Litmus Automation Q&A: An Intelligent Edge Computing Platform

A few weeks ago, Litmus Automation announced LoopEdge 2.0, the latest iteration of their edge computing platform designed to seamlessly connect all industrial assets and derive value with instant analytics. We asked COO John Younes to share a few details about the changes with our readers.

John, can you describe LoopEdge for those who are new to the edge computing platform?

LoopEdge is an edge computing platform that lets you collect data from industrial systems like PLCs, DCS, sensors or historians and run applications locally on top of the data, such as event processing, Lambda functions, machine learning models, and more – all in an offline first deployment. LoopEdge runs on any IoT gateway, industrial PC or as a VM. LoopEdge is carefully designed to manage the complete edge lifecycle from secure edge device onboarding to device management to cloud connectivity.

Who is the target market for LoopEdge 2.0?

Any industrial customer can benefit from gathering intelligence from their industrial systems. Let’s take a boiler manufacturer for example – they can use edge computing in industry to monitor system health, temperature, steam, and other data points at their customer sites. Now, they could just collect that data and send it to the Cloud, but the real value comes when you have intelligence at the edge. When that boiler manufacturer’s customer can see that over a period of a week the average temperature of the boiler has gone up a few degrees. The customer can then be notified and make changes on the fly to ensure the system does not fail.

Why was it time to launch the next version, LoopEdge 2.0?

We have been listening closely to our partners and customers, and the number one thing they have been asking for is out-of-the-box analytics components inside of LoopEdge. One of the most common pieces of feedback we heard was that customers could see the visualizations on the factory floor, but they couldn’t do long running visualizations on the factory floor.

LoopEdge is already proven – customers are using it to get their edge computing projects up and running quickly and on budget. However, the new features will make it even easier to derive business value from industrial assets in the field.

Tell us about those new features – let’s start with an analytics database for data and event processing at the Edge.

As Industry 4.0 matures, we have seen a shift in what our customers are doing at the Edge. First, and with the first version of LoopEdge, they were collecting data from industrial systems, processing it, and then making it available to a third-party system via the Cloud, local marketplace, or some other OPC-UA interface. That was the focus – collect the data and make it available to the system they want to consume the data. Sometimes we would cycle back a feedback loop to the operational technology. That is all well and good but we are always thinking about how we can make better use of that data at the edge.

So, with LoopEdge 2.0 we added more intelligence. We can collect data from any industrial device, process the data, and now we have brought in a long running database and analytics tool to run locally, inside of LoopEdge. Now, every data point we are collecting has integration into the local database, which allows us to store data at the edge for longer periods of time. We are moving away from the “collect and forward” method to a smarter, “collect, process, analyze, store, and then integrate” method.

The database we added to LoopEdge 2.0 allow us to instantly do some local real-time analytics, or batch long-term analysis. Think simple things like – if the boiler manufacturer wants the average temperature for the last week. Now they don’t have to send data to the Cloud for that analysis. They can get it right at the edge.

What else did you add to LoopEdge 2.0?

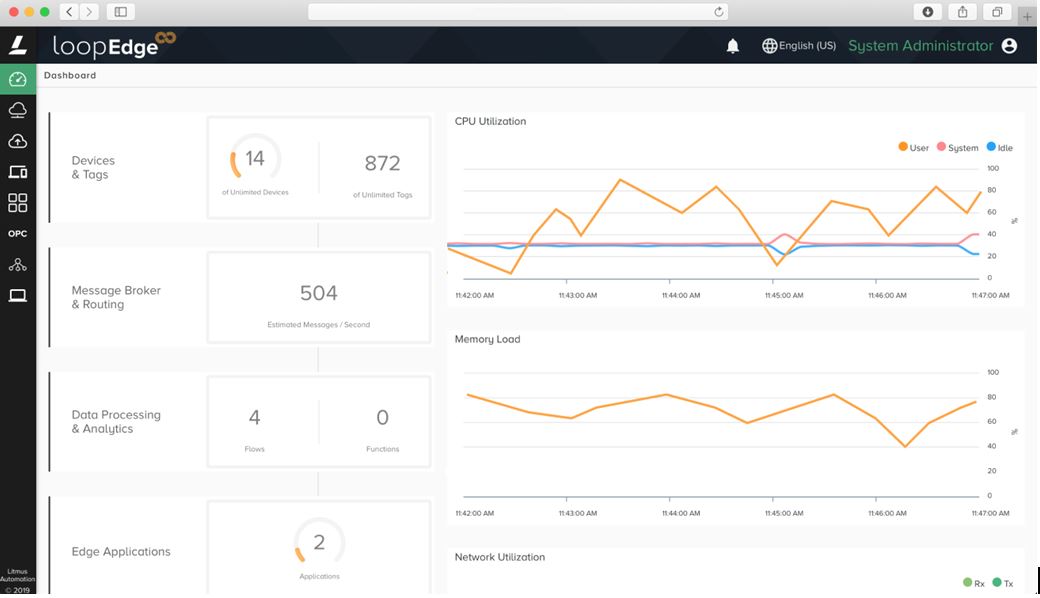

We launched several new integrations such as leading IoT Clouds Azure, AWS, Google IoT Core, and others. We integrated with big data platforms, enterprise software, and cloud or on-site databases. We expanded our advanced marketplace for running artificial intelligence and machine learning applications at the Edge. LoopEdge 2.0 also adds increased device management functionality for real-time monitoring and management. We refreshed the user interface (see dashboard screenshot below) and added a full OPC-UA server at no cost.

There were a lot of updates – but still – the most important is the analytics database for seamless data and event processing at the Edge.

Where are you going next with LoopEdge?

We want to continue to utilize data at the edge for real-time analytics. As we continue to work on the product we will add more analysis features, specifically Ready Apps. Ready Apps represent even more value for the customer if they can access real-time data from our system, and then connect to an app for a final solution such as cybersecurity, asset management, etc.

John Younes is the Co-Founder & Chief Operating Officer at Litmus Automation. He is in charge of operations and growth for the company and draws on considerable experience working with start-ups and early stage companies. He has a Bachelors in Management from University of Western Ontario and a Masters in Management with specialization in Global Entrepreneurship from EM-Lyon.