Signal Conditioning and Circuit Protection: Critical pieces of IIoT and Automation

The Internet of Things (IoT) and the Industrial Internet of things (IIoT) have reached a stage where the hype has now started to see the reality. Every day, we get to hear about new and innovative use cases of IoT and IIoT. As we progress, we are likely to see more adoption of IoT, more use cases and the latest innovative solutions coming into the market. While this is happening, I would like to bring to notice two aspects of IoT/IIoT solutions that are critical – Signal Conditioning and Circuit Protection.

Signal Conditioning and Circuit Protection are seldom talked about in any IIoT or Industrial Automation activity. However, these key blocks form a critical part of IIoT and the Automation ecosystem.

So what exactly is Signal Conditioning and Circuit Protection and why are they important?

What is Signal Conditioning?

Simply put, Signal Conditioning is the processing of a signal such that it meets the expectations of the next processing stage. There could a wide range of next stage requirements, depending on the sensors and use cases. One of the most common use cases is Analog to Digital conversion of a signal.

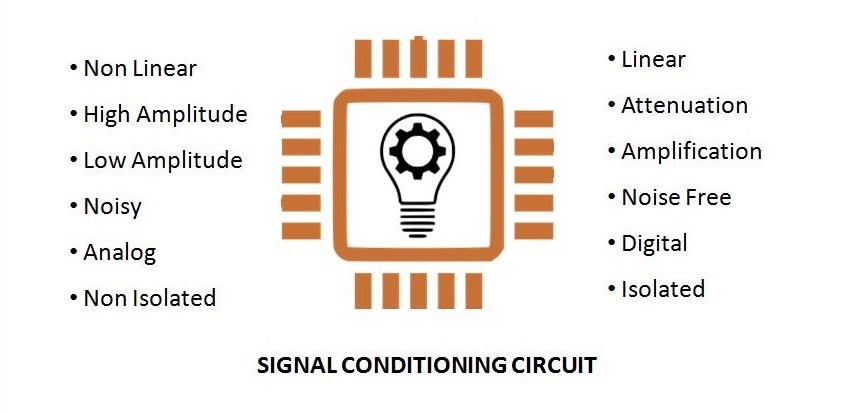

Additional use cases of Signal conditioning are Signal Isolation, Amplification, Attenuation, Range matching or any other signal processing requirement that makes the output suitable for the subsequent stage. The below figure illustrates some of the examples of signal conditioning.

Various types of industries need to measure environmental or structural parameters as part of their signal processes. So before a signal/data is being fed into a data acquisition device, a signal needs to be conditioned for accurate and effective recording of data.

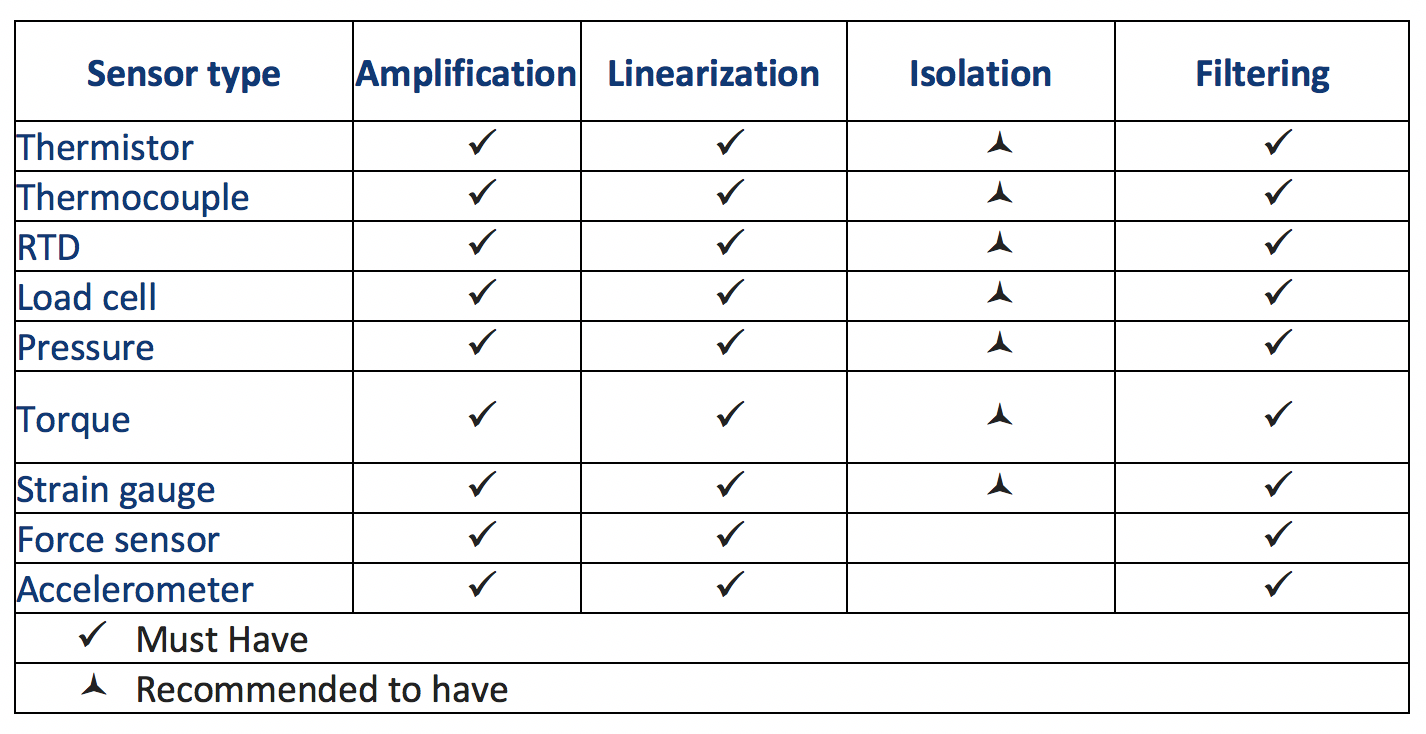

Different sensors require different signal processing to be deemed for the next stage process. Some sample actions based on sensor types are as mentioned in the table below:

Advantages of Signal Conditioning

- Data Quality: IoT is set to generate tons of data. If the data quality is not good, there would be too much of garbage and the cleaning may consume time and computing power.

- Accuracy: Assists in improving the data accuracy

- Efficiency: Improves the efficiency of the managed process and “Thing”

- Optimized Bandwidth: Effective use of signal conditioning helps in optimizing the bandwidth and help save on money

- Cost Advantage: Adds to the bottom-line by ensuing quality data, improving the efficiency of the overall process and reducing the costly bandwidth

- Flexibility: brings flexibility of processing into vast range of signals.

Need for Protection Circuit

Circuit Protection or Protection circuit is needed to protect the connected systems from possibilities of electric surge, overheating or electrostatic discharge. Connected systems are more susceptible to failures because of these factors. Protection circuit is an important factor in determining the reliability, product lifespan and energy efficiency of IIoT solutions. The industrial automation ecosystem generally starts small and increases in size with other systems connecting with it. Hence, Circuit protection is an essential part of the ecosystem for ensuing high availability and reliability of such ever expanding system.

Industrial IoT systems are designed to operate independently, while many of these systems operate in remote areas, unmanned, for their entire lifespan. One of the classic examples is of windmill operations. These systems are exposed to harsh weather such as excessive heat, wind, rain, thunder, lightning burst as well as electrostatic discharge. In order to ensure the long life and efficient functioning of such system, Protection circuit plays a vital role.

As more and more devices gets connected or as increasing number of electronic components are fitted into an electronic circuit, the chances of electrostatic discharge increase. Further, as the IoT infrastructure expands, the necessity of having a robust and stable protection circuit increases. All the components of an IoT ecosystem such as sensor nodes, edge devices, gateways, and computing platforms will require protection throughout their design- right from AC power connections to digital ports, down to the circuit board level.

The fundamentals of IoT or Industrial IoT stand true when even a remote device is capable of sending accurate and continuous data. The benefits of having a stable and robust circuit are both financial and technical. Undermining the threat of electrical transients can lead to heavy losses that can impact the productivity, efficiency and in turn add to financial losses as well.

Conclusions on Signal Conditioning and Circuit Protection

To summarize, IoT solutions, especially when deployed in an industrial environment, need to be rugged, sustainable, reliable and meet the stringent requirements prescribed by various industry councils. So when it comes to designing a solution for Industrial IoT, signal conditioning and circuit protection are as critical as any other piece of the puzzle in the IoT ecosystem.

![]() This article was written by Ajay Kamble, the Co-Founder and CEO at AMWick Technologies Pvt. Ltd. He carries close to two decades of experience in IT and has worked with various renowned IT MNCs.n the past he has played various roles such as Product Management, Presales and Sales, Process and Technical Consulting, Marketing, Solutions and Architecture etc. Ajay holds Engineering degree and is an MBA from reputed institute in India.

This article was written by Ajay Kamble, the Co-Founder and CEO at AMWick Technologies Pvt. Ltd. He carries close to two decades of experience in IT and has worked with various renowned IT MNCs.n the past he has played various roles such as Product Management, Presales and Sales, Process and Technical Consulting, Marketing, Solutions and Architecture etc. Ajay holds Engineering degree and is an MBA from reputed institute in India.