Are you ready for the Digital Twin?

We often hear the term “Digital Twin” in the context of the Industrial Internet of Things, Digital Transformation, or just going digital—and no this is not about Avatars! Most often we think about Digital Twin for machinery failure prevention, but benefits go well beyond including process optimization, lowering the cost of production, and decreasing the carbon footprint of the enterprise. In this article, I will be laying out step by step how to holistically assess maximum benefit for your Digital Twin transformation initiative.

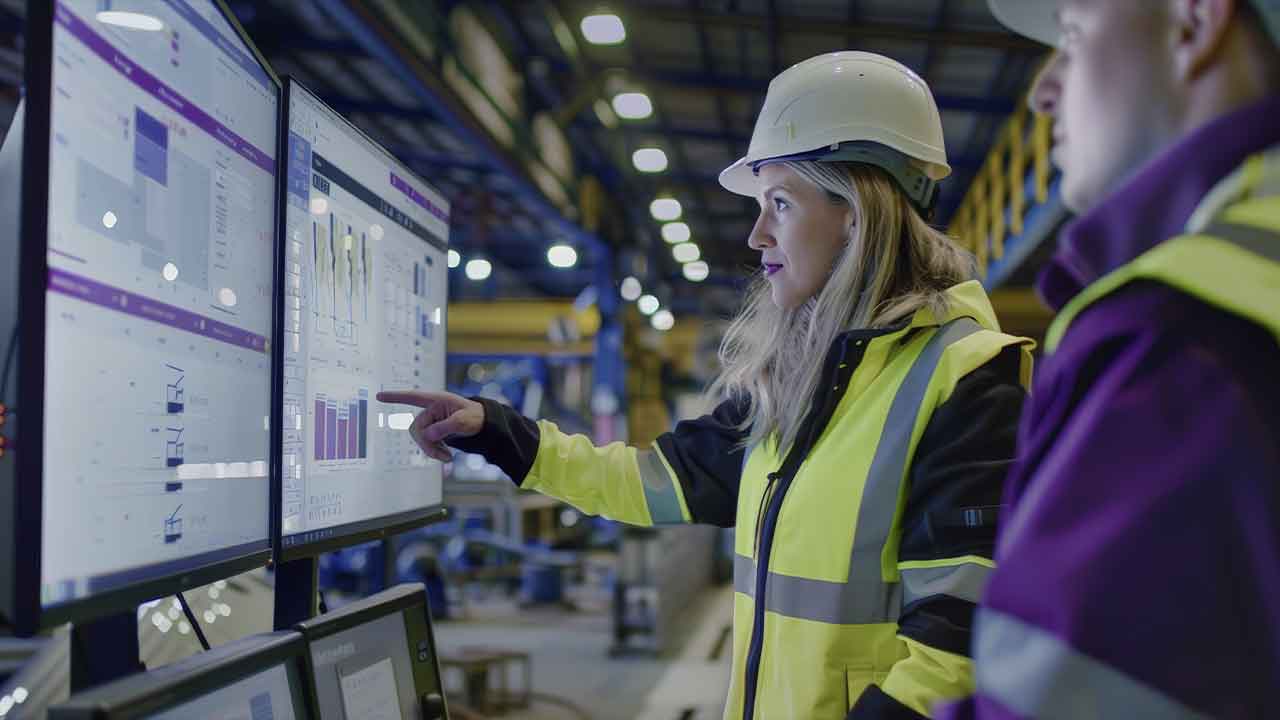

The most common question we hear from customers is “Where do we start?” The answer is to look at what critical manufacturing processes will have the greatest impact on profits. By starting with the strategic business perspective and understanding profit drivers, we can tailor any digital efforts on those that impact business profits (or risk or costs).

The next step is to identify the critical assets and components in the plant. What data is available from these assets? We are typically interested in engineering data including performance specifications, process, and instrumentation diagrams (P&ID), repair and maintenance manuals, operational manuals, and drawings (both two dimensional and three dimensional). We are also interested in machinery and equipment data. Can we pull data from the equipment controllers in real-time? What network infrastructure is in place or can be added to connect the data to our digital twin? Do we need to add sensors and instrumentation to obtain the data we need to make decisions that will drive our business Key Performance Indicators (KPIs)? These are just a few of the questions that need to be addressed to ensure success on the digital twin journey.

Next let’s take a look at Digital Twin Components, Connectivity, and then we’ll bring it all together:

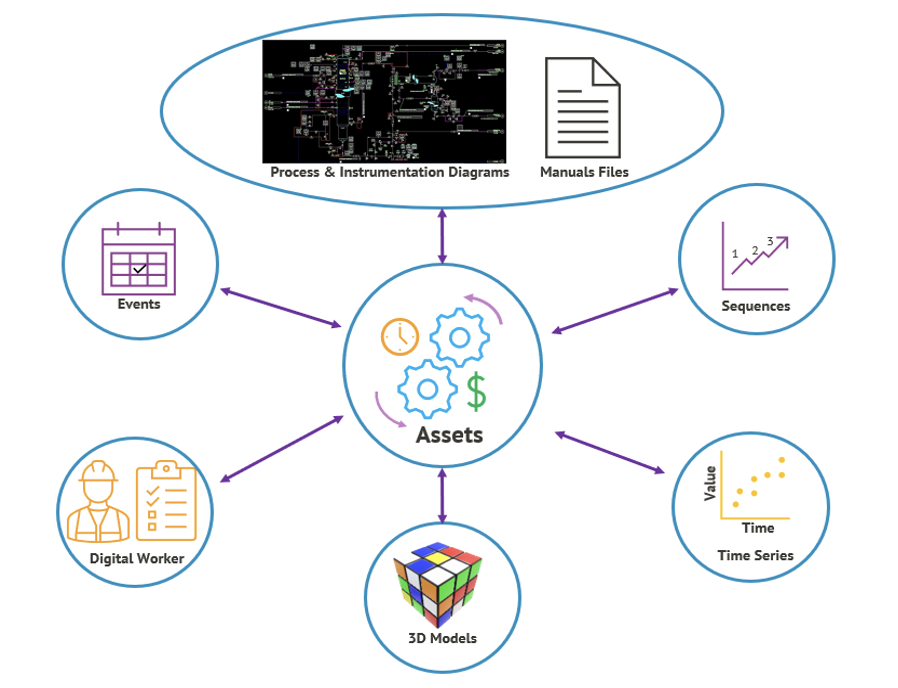

Digital Twin Components:

The asset (equipment or system) is at the core of the digital twin. There is a range of real-time data including time series, maintenance and operation events, and worker operator activity associated with the event. There is static data including engineering documentation, manuals, and three-dimensional drawings.

As an example, a feed pump may be part of a distillation column, and is listed on the P&ID. A digital operator notes his production schedule event and starts the feed pump. The feed pump automatically executes a series of start-up steps and checks. This is the start-up sequence. Motor current and vibration data from the pump is logged along with temperatures, pressures, and flows. These are time series data.

The operations manuals provide limits on any of the data, sequence timing, etc. Our three (or two) dimensional models provide any visualization that is helpful to the operator or to management.

Data Connectivity:

It may seem obvious, yet our digital twin needs access to core data. Data resides in our control system and data historian. Data resides in our maintenance management and operator management systems. Data resides in our engineering archives. It is likely that the data and systems are provided by multiple vendors, each with their own application programming interface. We need to identify where the data is, that will empower our digital twin.

We will also need to address our networking and security parameters as well. For example, we can use OPC UA to pull data from the control systems. OPC UA gives us security layers and can work across firewalls. OPC UA will allow us to see time series data, some sequence related data, and data that maps to events.

In other cases, we will need to access or implement digital versions of our management processes. These are business and process sequences we may wish to automate. We will need to access and manipulate our engineering data, those manuals, and P&IDs. It is likely we will need some help from natural language processing, or similar tools to interpret the engineering data. In the case of multi-dimensional drawings and models, we may need augmented reality resources that can bring the drawings to life. Lastly, we will want to bring our plant field personnel into the digital twin by adding smart devices for digital workflow, and access to digital twin information.

Bringing it all together:

Participating in the new digital industrial environment requires digital thinking, that is digitizing and automating many of our manual processes. However, these are often a two-to-three-year journey. For this journey, we will need support at the top of our organization, which may include cultural and change management efforts.

To keep the effort moving, it is recommended that companies partner with integration teams with expertise in operational technology (OT) and information technology (IT) and that have expertise in the company’s manufacturing process. Experience yields the ability to anticipate and overcome challenges that are likely to arise.

With these implementation elements in place, the team is ready to scale and ultimately transform the organization into a new digital entity. Machines will be more reliable, processes more efficient, energy consumption lower, and achieve a more profitable and competitive enterprise.

About the author

This article was written by Preston Johnson, a Senior Solutions Manager with CB Technologies, Inc. (CBT). As a solutions manager, Preston focuses on Monitoring and Analytics as he assists clients begin their digital journey. Preston is also the Chairman of the Society for Machinery Failure Prevention Technology (MFPT). Preston is MFPT chair of the Data Management and AI focus group, and a fellow of MFPT.