Industry 4.0: What It Means for Your BMS/SCADA | SPONSORED

You’ve automated your operations. You’ve identified key data points. All the pieces and parts are in place to give you the insight you need into your building’s performance.

Then along comes Industry 4.0, the Industrial Metaverse.

Is this a fad or a next-generation innovation? Is Industry 4.0 something to “wait and see” or an “I need to get on board with this” phenomenon? More importantly, what does the Industrial Metaverse mean for your Building Management System (BMS) or SCADA (Supervisory Control and Data Acquisition)?

The Industry 4.0 bandwagon is here, so before you decide whether to jump on, let’s talk about what it is and how it can help you meet your most pressing Industry 4.0 challenges.

What is Industry 4.0?

Industry 4.0 (also known as the Industrial Metaverse) is an evolving concept and not something that is easily defined—yet. The best definition we’ve found, however, comes from the International Society of Automation’s publication arm, Automation.com:

“Industry 4.0 is not merely a matter of connecting machines and products through the Internet. It encompasses a wide range of advanced technologies, such as digital twins, artificial intelligence, high-speed wireless networks, deterministic wired networks, cloud and edge computing, and virtualization technologies like augmented reality.”1

In other words, Industry 4.0 is a digital transformation concept that enables the delivery of real-time insights, which can be used to improve products, processes, and production.

Central to Industry 4.0 is something we’ve all been immersed in for a while: data.

The fact is, this is a data-driven world—and that world includes building automation, industrial automation, life & safety, and OEMs (original equipment manufacturers). The amount of data has grown beyond anything any of us have seen. And now, thanks to Industry 4.0, data’s usefulness to transform operations is growing, too.

Why the Industrial Metaverse Matters

Perhaps it’s difficult to imagine how this new concept could directly impact your operations. So, we’d like to offer an example to help illustrate Industry 4.0’s potential.

Introducing, the Smart Factory @ Wichita, a project that’s the brainchild of consulting services firm Deloitte and Wichita State University. According to Deloitte this is a project that demonstrates how advanced technologies and intelligent automation can help organizations overcome their biggest challenges, whatever they may be.

There’s a lot going on over at the Smart Factory @ Wichita. The real point is that this isn’t some futuristic, sci-fi notion. Rather, it exists to demonstrate what was once imagined has now become possible.

For you, that could mean leveraging Industry 4.0 to bring data-driven processes and automation to mission-critical operations. For us, it’s something we’ve been working toward for quite a while now.

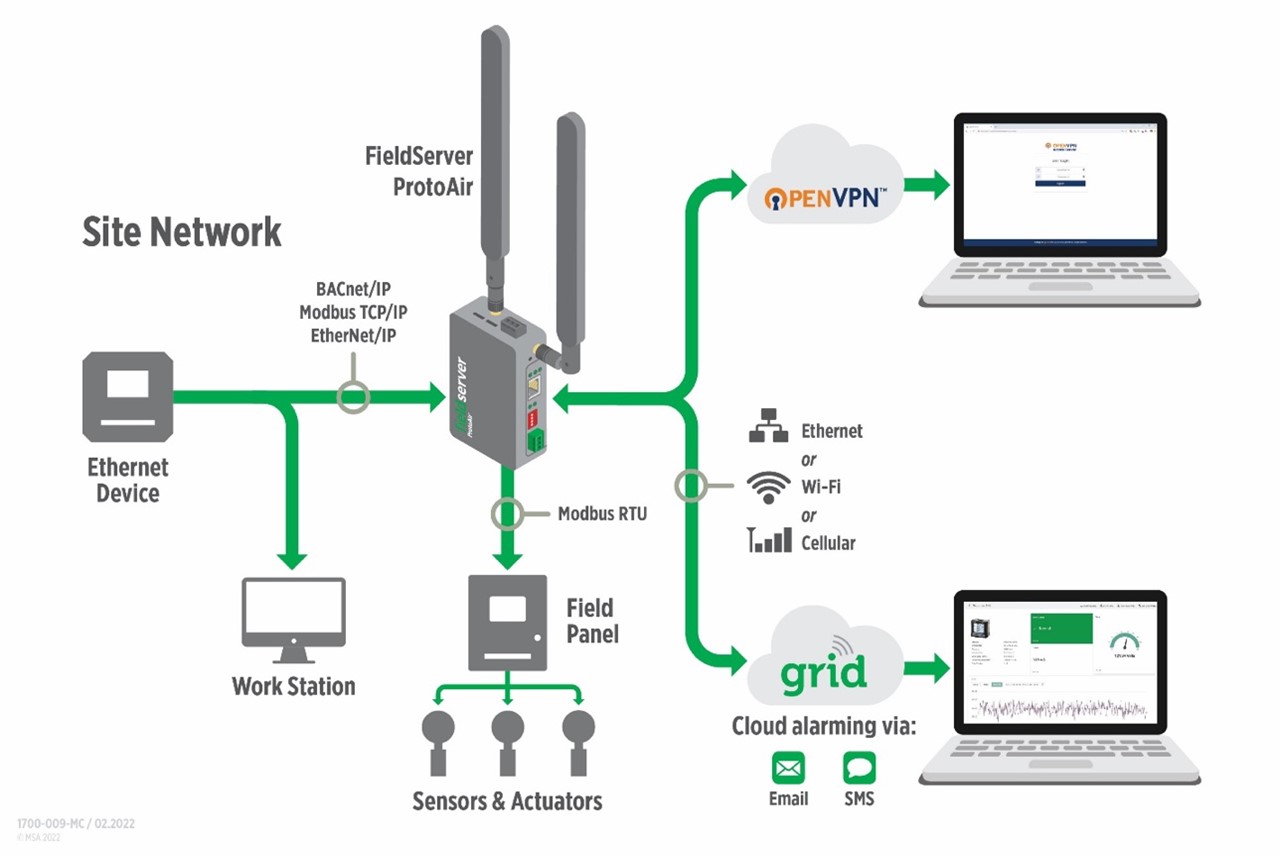

In fact, our FieldServer and the MSA Grid were early players in Industry 4.0 solutions, so this is a great starting point for building managers and systems integrators who are relatively new to the Industrial Metaverse. Using our experience working with companies in energy metering and others in connected machine data-to-Cloud applications, MSA FieldServer can help you leverage Industry 4.0 initiatives so you can bring together the processes, people, and places that fuel your operation.

Information Sharing Is Key

Now the question becomes, “How can Industry 4.0 help transform buildings, operations, and systems to make them faster, safer, and more efficient?”

The answer: information sharing.

Industry 4.0 can enable more and better use of the data contained within organizational resources, such as smart devices and the BMS or SCADA. For example, here at MSA, we’ve recently introduced the ALTAIR io™ 4 gas detection wearable to gas detection customers who are looking to support a stronger, more proactive culture of safety and performance. More about A Cloud Based Alternative to Traditional SCADA

Among its many features are visual compliance indicators, device lock-out capabilities, device health statuses, digital tagging, and more. Plus, as an Industry 4.0-enabled solution, our ALTAIR io™ 4 customers can now live-monitor their workers across their organization’s entire footprint, as well as enable automatic updates, provide real-time situational awareness, automate inventory management, and much more.

While you may not need gas detection in your workplace, it’s likely that you do (or will) need to know the “who,” “what,” and “where” of other operational aspects. Industry 4.0 can make that happen.

And though Industry 4.0 is still an emerging concept, device manufacturers like Siemens and Rockwell Automation have already created Industry 4.0-enabled smart devices, which are specifically designed to collect the data points needed to make the best possible informed decisions. MSA FieldServer™ is participating in Industry 4.0, too, by ensuring that this all-important data gets delivered to the appropriate destination.

Should You Jump on the Industry 4.0 Bandwagon?

Should You Jump on the Industry 4.0 Bandwagon?

Only you can decide if Industry 4.0 is right for you. However, Industry 4.0 is proving to be the go-to innovation for enabling more meaningful data collection, dissemination, and analysis.

Industry 4.0 also supports the integration of physical and digital technologies/assets across an enterprise, including Cloud computing technologies and Industrial Internet of Things (IIoT) devices. This means you can have persistent, digital visibility into your physical operations, and tap into next-level insights—insights that can literally change the way you operate. Find out if Internet of Things is going to replace SCADA systems.

This article was written by Richard Theron, Product Manager at MSA, and originally it was published here.