AI is the Future of Manufacturing, and It’s Already Here

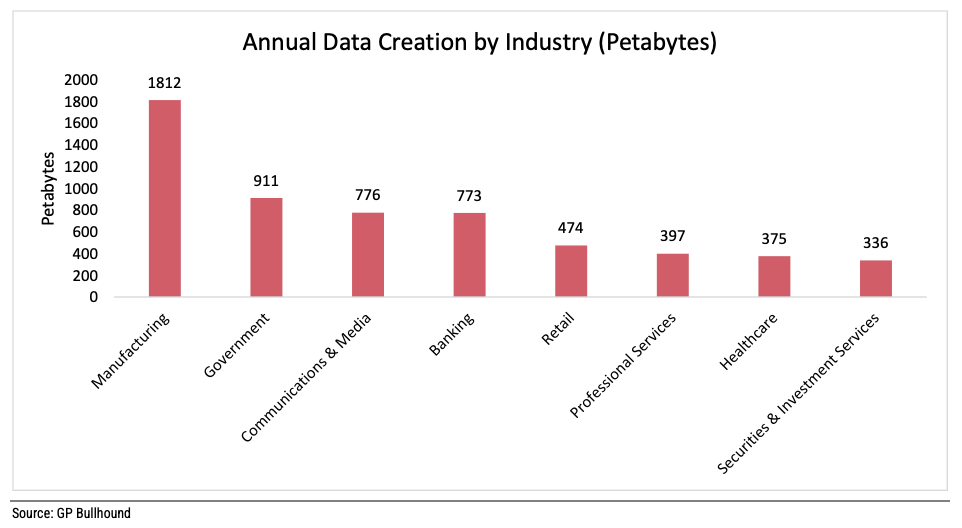

Costly machine maintenance, inefficiencies, and faulty products are some of the many issues plaguing the manufacturing industry. But thanks to a combination of human know-how and artificial intelligence (AI), data-driven technology, better known as industry 4.0, is reshaping the entire sector. With the advent of the Internet of Things (IoT) and factory automation, much daily data is being produced. AI plays a crucial role in turning these raw data into meaningful insights. According to GP Bullhound, the manufacturing sector generates 1,812 petabytes (PB) of data yearly, more than other industries such as BFSI, retail, communications, and others. Manufacturers are adopting the AI solutions like machine learning and deep learning, natural language processing to analyze data better and make decisions.

FIGURE 1 ANNUAL DATA CREATION BY INDUSTRY (PETABYTES)

Future Applications of AI in Manufaturing Industry

AI has several applications in every manufacturing phase, from raw material procurement and production to product distribution. The key application of AI is predictive maintenance. By applying AI to manufacturing data, manufacturing enterprises can better predict and prevent machine failure. This, in turn, cuts down expensive downtime in manufacturing processes. AI in manufacturing has many other potential uses, such as improved demand forecasting, quality assurance, inspection, and warehouse automation.

AI is crucial to the concept of “Industry 4.0,” the trend toward greater automation in manufacturing factories, and the enormous generation and transmission of data. AI and ML are necessary to ensure that organizations can unlock the value in the vast amounts of data created by manufacturing machines. Applying AI to this data can lead to greater cost savings, safety improvements, supply-chain efficiencies, and other benefits.

In the context of AI in manufacturing, the sub-technologies such as machine learning & deep learning, natural language processing, and machine vision play a crucial role in the various processes.

Future Technologies used by AI in Manufaturing

There are two types of machine learning technologies used in manufacturing such as supervised and unsupervised machine learning. Supervised machine learning involves leveraging AI to draw patterns from large data sets with a predefined end. This is specifically useful in determining the remaining useful life of a machine and the probability of specific equipment failure. At the same time, unsupervised machine learning concerns itself with identifying patterns from data sets whose outcome isn’t yet known. For instance, engineers can use ML technology to spot unknown anomalies and faulty components in production lines.

Deep learning is still small but gaining significant momentum in the process industries. Process manufacturing factories produce massive amounts of data and frequently encounter complex analytical issues, making deep learning a valued tool for manufacturing companies.

Natural Language Processing (NLP) helps identify key elements from human instructions, extract relevant information, and process them so machines can understand. NLP technology has multiple use cases in the manufacturing sector, such as process automation, inventory management, emotional mapping, operation optimization, etc.

Furthermore, AI-based machine vision is used for monitoring manufacturing and industrial environments. Machine vision uses the latest AI technologies to allow industrial equipment to see and analyze tasks in smart manufacturing, worker safety, and quality control. At present, AI-enabled machine vision technologies replace labor-intensive, inefficient operations for greater efficiency, reliability, and security. AI smart cameras are gaining widespread acceptance for high-speed machine vision applications. Nowadays, AI-based leak detection is being widely deployed in the process industries. For instance, AI-based cameras detect a leak of chemicals or gas in real time and help technicians diagnose leaks quickly and accurately. This technology has significant potential and has demand across industries where hazardous gases or chemicals are processed and produced.

Robotics will play a major role in the futire of AI in Manufaturing

The major revolution that can bring AI into the manufacturing sector is robotics. AI-enabled robotics can help robots learn like humans, which could have a massive impact on traditional manufacturing. Robots are inflexible by design, but AI-enabled robotics that use sensors, data-driven computation, and more can enhance their capabilities. Robots can function more intelligently by combining AI, ML, and DL into robotics, mainly through machine vision. The primary wave is coming in robotics, known as Generative AI. Robots equipped with Generative AI technology can identify and navigate obstacles, recognize human gestures, and even learn from their mistakes, making them suitable for applications such as manufacturing, logistics, healthcare, and many others.

Today, AI technology has gained rapid adoption in the discrete industry compared to the process industry. The manufacturing sub-sectors such as automotive/OEMs, heavy machinery, semiconductors & electronics are the dominant end-users that leverage the AI technology. The process industries such as energy and power, food and beverages, and pharmaceuticals are the major end users utilizing AI technology in daily operations. The key trend is witnessing the use of AI technology in smart grids. AI technology is transforming the energy grid by offering new ways to monitor and optimize its performance. AI-powered tools can assist utilities in managing the power grid by providing real-time monitoring and predictions of system conditions. AI has several applications in the energy grid, such as condition monitoring/predictive maintenance, load forecasting, predicting future behavior, outage predictions & response, demand management, and so many others. More about The Role of IoT in Smart Grid Technology and Applications

The Potential of AI to Transform the Future of Manufacturing Industry

AI has massive potential to transform the manufacturing industry, and 81 percent of companies believe AI produces better results. Still, only 22 percent have adopted it, according to a survey conducted by Market Research Future. Many companies need more expertise to leverage AI technology; domain expertise is essential for successfully implementing AI in the manufacturing industry.

According to Market Research Future, “the global AI in manufacturing market was valued at USD 2.45 billion in 2022 and is expected to grow from USD 3.61 billion in 2023 to USD 53.69 billion by 2030 with a CAGR rate of 47.1% during 2023-2030”. Currently, the AI penetration is still less, and it is expected to grow during the upcoming years owing to the industry 4.0 era, favorable regulations, surges in automation, and AI investments by tech companies. The market is expected to open massive revenue opportunities for the market players during the projected period since there is significant potential for the market in developed and emerging economies. Currently, the global AI in manufacturing market is dominated by the countries such as the US, China, Germany, the UK, France, Italy, Japan, India, and South Korea.

However, as advances in AI take place over time, we may see the rise of entirely automated factories, product designs made automatically with little to no human control, and more. Fifth Industrial Revolution (Industry 5.0) is already begun with the use of AI technology alongside humans. However, there is still needed to continue the trend of innovation. More ideas, unification of technologies, new use cases, and advanced innovations will further accelerate the adoption and completely transform the manufacturing market landscape.

More about How IIoT enables the factory of the future

About the author

This article was written by Shubham Munde, Senior Research Analyst, Market Research Future.