The Benefits of Artificial Intelligence of Things (AIoT) in Modern Oil and Gas Leak Detection

|

Getting your Trinity Audio player ready...

|

The oil and gas industry is undergoing a profound transformation, driven by a realization among plant managers and engineers of the imperative to reassess business processes related to fugitive emissions. There’s a compelling need to modernize emissions detection, moving from conventional manual routines to a technology-first ethos.

Fugitive emissions, including Greenhouse Gases (GHGs), Volatile Organic Compounds (VOCs), and other pollutants, emerge from various sources such as drilling, process equipment, human error, and unmonitored components. These emissions pose significant challenges, especially in industrial settings like oil refineries, petrochemical plants, or processing facilities, leading to severe consequences such as unsafe conditions, unexpected downtime, fines, shutdowns, and environmental impact.

The challenges in current leak detection procedures are multifaceted, including the complexity of industrial processes, numerous potential leak sources—especially in remote locations—and constraints like limited equipment access, error-prone manual methods, and environmental conditions impacting accuracy. An additional hurdle is the outdated schedule-based maintenance approach, imposing financial risks on plant operators. The effectiveness of the process to detect, investigate, and rectify emissions is only as robust as its weakest link, with early issues escalating rapidly, causing negative impacts throughout the plant facility.

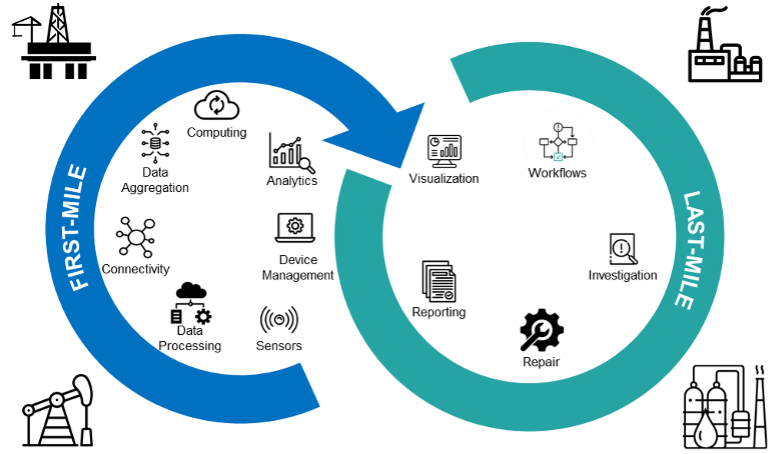

First-Mile Mastery: Building the Strongest Link

Despite the gradual pace of technology adoption in the industry, a silver lining exists for refineries, plants, and process facilities. They can now leverage the transformative power of Artificial Intelligence of Things (AIoT) technology for proactive decision-making to curtail emissions. Addressing the “first mile” bottleneck becomes pivotal, where Industrial AIoT emerges as a transformative solution. By amalgamating smart sensors, AI, machine learning (ML) analytics, and timely alerts, the focus is on optimizing the “first mile” and seamlessly extending efforts to the “last mile” of emissions remediation. Key components of the first mile encompass data collection, processing, analytics, device connectivity, and management.

Operational and local environmental data emerge as invaluable assets in fugitive emissions management. Leveraging a broad spectrum of data, including air flow patterns across the facility, organizations can utilize sophisticated techniques to pinpoint leak locations and predict likely sources. The significance of the first mile lies in empowering organizations with real-time field data, facilitating timely decisions that yield enhanced efficiency, cost savings, and operational improvements.

First-Mile to Last-Mile: Second Nature for Operations

In the “last mile” of managing fugitive emissions, important elements contribute to effective and proactive management. This includes visualizing data through graphics to identify patterns and trends, while utilizing workflows to save time and reduce errors. The last mile considers time for investigation and repair, as promptly addressing emission sources is crucial. Swift implementation of necessary repairs or maintenance activities is essential for effective emissions management. Additionally, preventing fugitive emissions requires strategies such as equipment upgrades, process improvements, or enhanced maintenance protocols. Comprehensive record-keeping of emissions data, inspection findings, and reporting ensures regulatory compliance and transparency. These elements collectively enable a proactive approach to managing fugitive emissions, minimizing potential impacts on the environment, employees, and neighboring communities.

When it comes to data transmission and usage, prioritizing security and privacy is paramount, particularly during the vulnerable stages of the first and last mile. These critical points demand comprehensive security measures to safeguard sensitive data effectively. Plant operators can ensure data security by employing robust tools such as encryption, authentication, and access controls. These measures not only preserve data integrity but also restrict access solely to authorized individuals. A proactive stance on security and privacy not only ensures regulatory compliance but also underscores environmental stewardship. By fortifying sensitive data, organizations can avert breaches, instill trust among stakeholders, and uphold the confidentiality of critical information.

Unlocking the Potential: Clear Benefits of AIoT

It is evident that to mitigate fugitive emissions and enhance workplace safety, process industries need to revolutionize their emission detection methods and adopt cutting-edge technology. The integration of AIoT proves instrumental in translating extensive and intricate data into actionable insights. A pivotal component in obtaining reliable and actionable data for emissions reduction is the implementation of a continuous emissions monitoring solution spanning from the ‘first mile’ to the ‘last mile.’ This comprehensive approach empowers plant operators to realize substantial emissions reduction, bringing benefits to the business, the community, and the environment.

About the author

This article was written by Venkat Eswara. He currently holds the position of Senior Director in Product Management. He leads a pioneering Solution as a Service portfolio for process industries, seamlessly integrating cutting-edge technologies such as AIoT, Operational-aware Analytics, and Automation. His role encompasses portfolio strategy, roadmaps, go-to-market strategies, P&L management, and strategic partnerships.

This article was written by Venkat Eswara. He currently holds the position of Senior Director in Product Management. He leads a pioneering Solution as a Service portfolio for process industries, seamlessly integrating cutting-edge technologies such as AIoT, Operational-aware Analytics, and Automation. His role encompasses portfolio strategy, roadmaps, go-to-market strategies, P&L management, and strategic partnerships.