5 Ways Drones Are Transforming Earthworks Projects

Drones have quickly become one of the most versatile tools on the construction site. Whether it’s for documentation before pouring concrete, making pre-design processes more efficient, or speeding up data collection for infrastructure projects, drones have become the aerial eye of the jobsite, helping construction professionals work better and more productively.

One area that drones have had a big impact is in managing earthworks projects.

We’ve identified 5 key reasons why drones should manage earthworks projects:

Faster site surveying

For most field engineers, there’s a simple reason for using drones for earthworks: speed. It can take hours to walk the jobsite and measure aggregates and stockpiles with traditional workflows, and then it usually takes 1-2 days to process the data and produce the final deliverables. Drones are doing this work in a fraction of the time.

For example, one of our customers, PCL Construction, flew a drone at their jobsite in Florida and captured the entire area in less than 12 minutes. They then processed the images, and in a matter of hours they created an orthomosaic and a point cloud of the site.

Cut-and-fill made simple

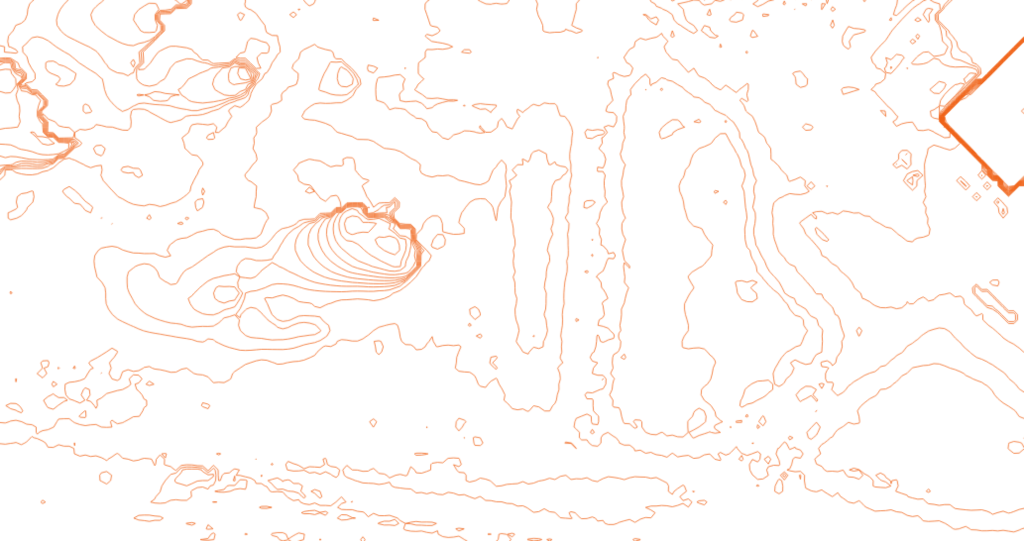

To perform cut-and-fill analyses and comparisons, most firms will conduct a topographic survey and collect points on a grid throughout their site. For large sites or areas with complex terrain, this survey can take days to perform, and post-processing the data typically takes another day. Drones have dramatically reduced the manual work needed to perform a cut-and-fill: once aerial data is collected, drone software platforms like Site Scan enables cloud processing and export into native Autodesk file formats like an RCS, a point cloud file that can be used in Civil 3D.

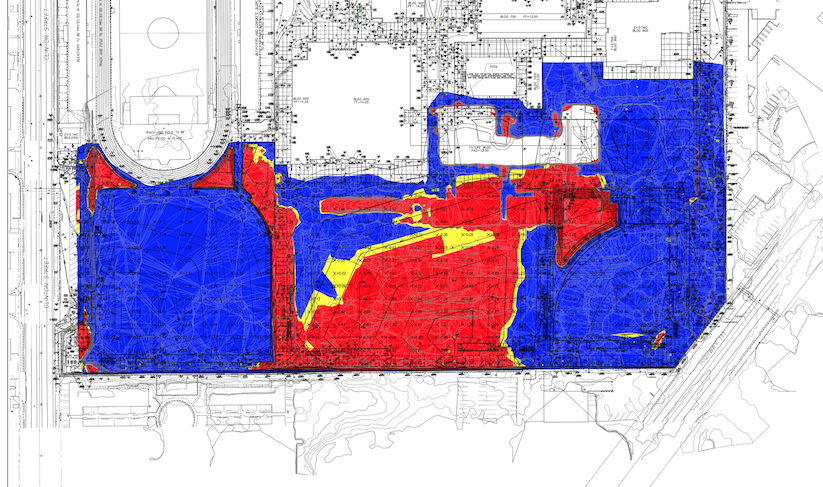

For example, one of our customer, Bogh Engineering, a family-owned firm building schools in California, created this cut-and-fill Analysis diagram after importing drone data into Civil 3D:

Cut-and-fill analysis using data from Site Scan

Bogh has been able to streamline their cut-and-fill workflow with drones, making it 4X more productive and empowering the whole team to get valuable insights with the push of a button.

Verifying work and managing conflicts

Whether your earthworks projects are self-performed or done by grading contractors, it’s vital to regularly monitor project progress, especially at key milestones and handoffs, in order to ensure that work is being done as planned. Collecting this progress data regularly has been a challenge in the past—for many firms, it’s too expensive and time-consuming to regularly document their site, and they often end up with gaps in their data that could have been used to improve communication with stakeholders or resolve disputes with subcontractors.

Drones have helped bridge this gap: many of our customers fly their site once per day, process their images into an orthomosaic, and then create an elevation map that can then be compared to the initial site plans as the project goes on. This helps document and monitor progress at important phases of the project and enables more focused quality control.

Streamlined cost estimates

To keep projects running smoothly and within budget, field engineers often do volume measurements to calculate the cost and labor time involved in managing their resources. By flying a drone, it’s possible to scan a jobsite in minutes, and then import the data into tools like Civil 3D and create a surface model that can be used for cost and labor estimates.

Improved worker safety

In the field, landfill personnel spends days walking piles and measuring aggregates with traditional survey tools. This is not only time-consuming, but it also puts them in harm’s way—they’re walking up and down steep slopes that are uneven and jagged, and it’s all too common for them to slip and fall. With drones, landfill personnel can inspect their stockpiles from a safe distance and not put themselves at risk—all while collecting millions of more points than ever before.

The article was written by Hugh McFall, Marketing Specialist at 3D Robotics in Berkeley, California. He tells stories about how construction and engineering professionals use Site Scan, 3DR’s drone to data platform, to save time and money and improve collaboration on projects. Originally the article was published here.

The article was written by Hugh McFall, Marketing Specialist at 3D Robotics in Berkeley, California. He tells stories about how construction and engineering professionals use Site Scan, 3DR’s drone to data platform, to save time and money and improve collaboration on projects. Originally the article was published here.