In recent months, augmented reality (AR) has gained much attention across both business and consumer marketplaces. Although AR technologies have been around for at least 15 years, mainstream adoption is a recent phenomenon within the manufacturing industry. New breakthroughs in the affordability and applicability of AR technology have accelerated the rate of adoption. Traditional AR installations involved expensive equipment, a complex rollout, and a high degree of technical expertise. Now, a flood of mobile devices such as smart phones and tablets combined with some innovative software engineering tools have made it possible for developers across industries to achieve affordable AR solutions. Manufacturing companies large and small find themselves in a position to capitalize on AR and to pursue new opportunities that significantly boost operational productivity and enhance competitiveness.

What is augmented reality?

Within the realm of industrial manufacturing, augmented reality is really about two different environments converging or blending in a way that boosts the effectiveness and efficiency of plant operators. One environment is “real” (what you see, unassisted, in front of your own eyes) and the other is “virtual” (not “real”, but computer generated). Both of these environments can be understood in terms of a continuum, with real environments at one end and completely virtual environments at the other. What lies in between is augmented reality, which is, in essence, mixed reality.

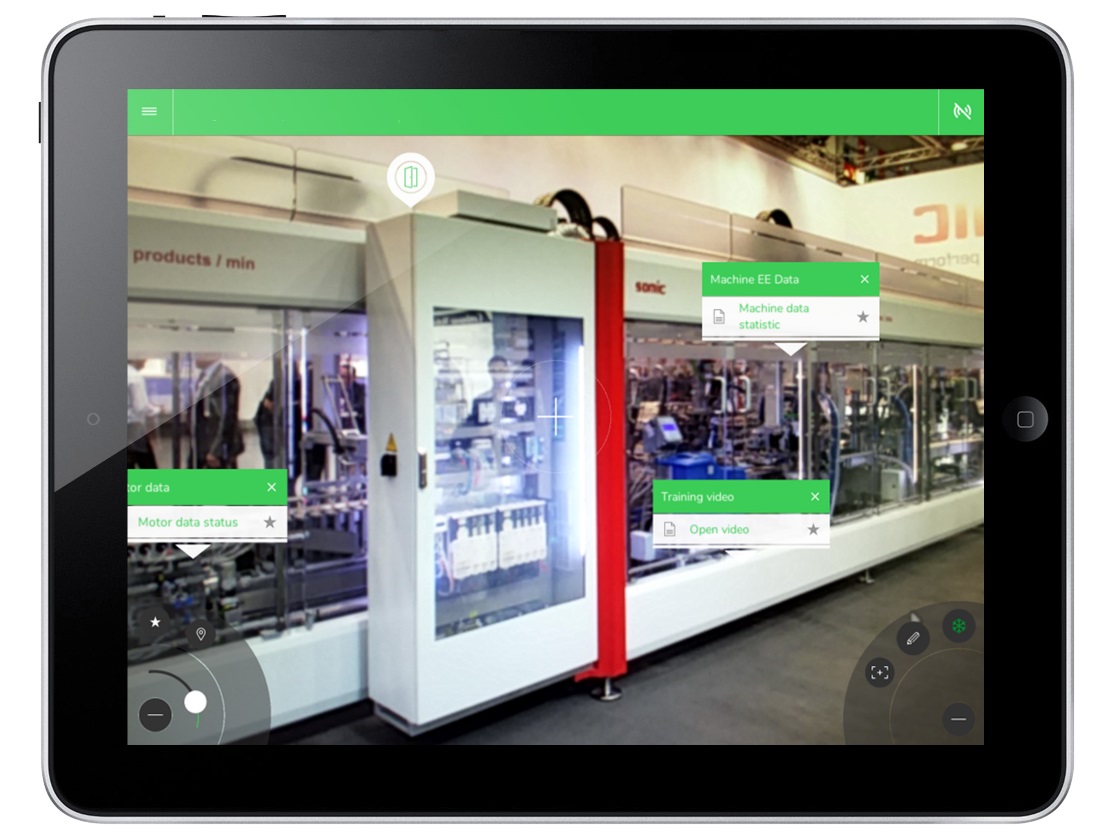

AR presents a completely new way of engaging with machine devices and executing tasks. The technology of mobile devices (and the cameras within) is combined with access to new sources of real-time data (usually via a wireless network) and the conversion of that data into visualizations/graphics. This offers operators a blended view that allows them to virtually see “inside” of a machine without having to open any doors.

For anyone that uses a mobile device for daily activities, AR presents a completely new way of engaging with machine devices and executing tasks. The technology of mobile devices (and the cameras within) is combined with access to new sources of real-time data (usually via a wireless network) and the conversion of that data into visualizations/graphics. This offers operators a blended view that allows them to virtually see “inside” of a machine without having to open any doors.

Practical applications

Consider the implication of such capabilities on three areas pertinent to manufacturing:

Product development – Augmented reality applications in IoT can be effective in the product design review phase, when new products require testing and evaluation. AR offers the possibility of evaluating 3D virtual models of new products, which can be easily modified, in their real context of use, without having to take the time and to bear the cost of producing real prototypes. More about the key role of Augmented Reality in Industry 4.0 for Manufacturing.

Maintenance – Suppose an operator’s machine breaks down. An AR app can diagnose the machine problem and visually guides the operator or maintenance person through quick and easy repairs. The AR program displays superimposed information on the operator’s tablet regarding how to execute the specific repair. More about How AR systems guide industrial operators in preventive maintenance activities

Safety applications – New AR applications allow the user to “see” the inside of a closed metal cabinet (that houses machine components) and allows the user to diagnose an issue without ever having to physically open the box. This allows internal environmental conditions to be assessed while equipment is still in operation (without humans having to get too close). This increases overall reliability and reduces safety risk involved with digital transformation.

Generating exponential benefits through “end-to-end” integration

Sophisticated AR tools do require a high degree of integration to perform these specific functions. Elements such as the physical environment, data sources, graphical interfaces, product specifications (including software and connectivity compatibility) and artificial intelligence all need to work together. In fact, AR tools perform best when connected with the broader upstream and downstream processes across the entire manufacturing value chain. Naturally, such complex programming should not be the responsibility of the end consumer, and that is why open and inclusive vendor-developed technology architectures are important enablers to large scale deployment of AR applications.

We are just now uncovering the potential for this new generation of AR tools on the plant floor. Although much progress has been made to get to this point, recent advances in easier integration and practical use cases should help speed the adoption of these solutions within the manufacturing space. In fact, 10 years from now we will realize that 2018 was just the beginning.

This article was written by Peter Herweck, EVP Industry Business, Schneider Electric. Peter began his career at Mitsubishi where he served as Software Development Engineer. In 1993, he joined Siemens in the Motion Control for Machine Tools unit where he led various R&D projects.

This article was written by Peter Herweck, EVP Industry Business, Schneider Electric. Peter began his career at Mitsubishi where he served as Software Development Engineer. In 1993, he joined Siemens in the Motion Control for Machine Tools unit where he led various R&D projects.