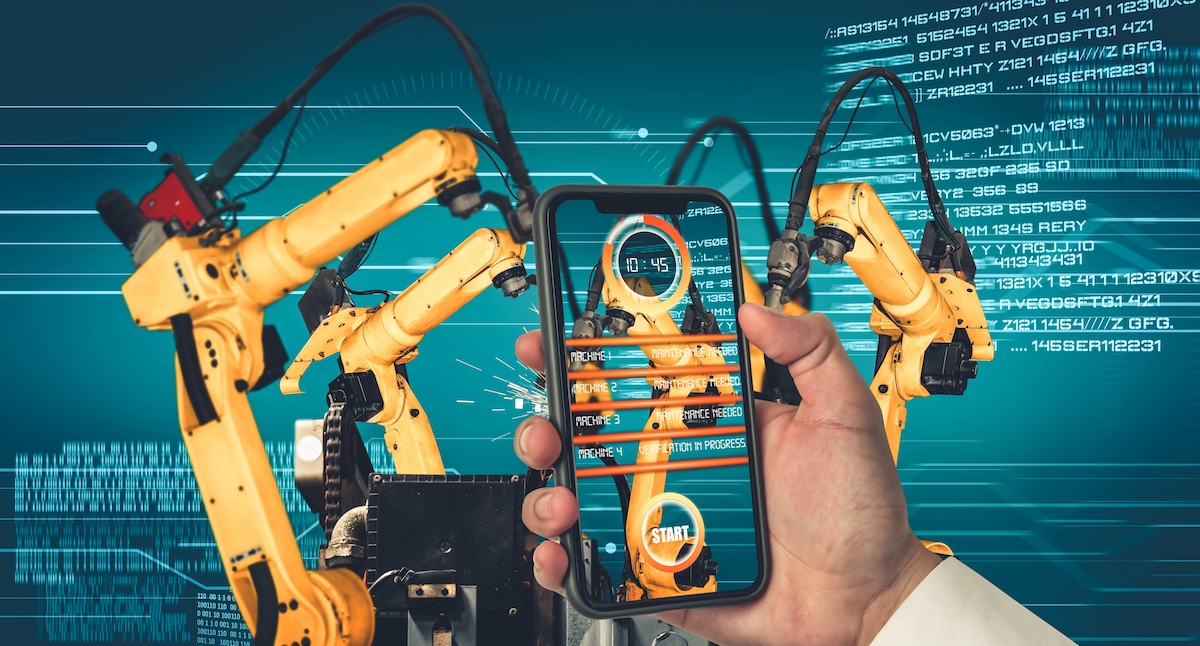

How AR systems guide industrial operators in preventive maintenance activities

Efficiency, safety, remote control: augmented reality systems guide industrial operators in preventive maintenance activities.

The advantages of augmented and virtual reality in industry 4.0 are considerable. In new construction projects, augmented reality makes it possible to intervene in the early stages and eliminate any criticalities. In maintenance, it improves remote assistance and preventive and predictive maintenance activities. Finally, in personnel training, it is possible to transfer skills to operators in a reality similar to the real one. The result is measured in operational efficiency, safety, customer service level and higher availability of the production asset throughout the life cycle of the investment.

Understanding Augmented Reality in Preventive Maintenance

Augmented reality (AR) is revolutionizing the landscape of Preventive Maintenance by providing technicians with an immersive and interactive platform to enhance their troubleshooting and repair processes. Through the integration of digital information into the real-world environment, AR overlays critical data, schematics, and step-by-step instructions onto physical machinery. This empowers maintenance teams with real-time insights, enabling them to identify potential issues before they escalate into costly breakdowns. Moreover, AR in Preventive Maintenance facilitates comprehensive training programs, ensuring technicians are equipped with the knowledge and skills required to perform their tasks efficiently. By bridging the gap between the physical and digital realms, augmented reality is redefining the way maintenance is conducted, leading to increased operational efficiency and reduced downtime.

The importance of AR (Augmented Reality) in Industrial Maintenance

IoT acts as a bridge between physical assets and digital infrastructure, while AR brings digital to life by interacting with the physical environment in real time. Let’s take the example of workers and engineers accessing IoT data in real time on the shop floor, where these technologies are implemented to achieve the best possible result: Augmented Reality devices are aware of the spatial configuration of the environment where the worker is operating, and can therefore perceive what he is looking at, to intuitively display only the data needed for the current operation.

These Augmented Reality and IoT applications can be applied to maintenance management in remote locations, low visibility and unfriendly environmental conditions and other dangerous situations: in a way, the possibilities are truly endless.

The role of IoT and AR in preventive maintenance

The IoT-AR pairing offers a number of business benefits, such as:

– standard quality improvement: AR encompasses a range of systems and technologies that provide practical real-time guidance to ensure that tasks are completed safely, correctly and efficiently.

One of the most important features that make this type of standardization possible is the “no faults forward” functionality that must be built into the system. This ensures that steps are completed in the correct sequence before allowing the user to move on to the next step in the process. This, in effect, eliminates most inaccuracies that result from human error and ensures that the right steps, processes and sequences are always followed.

– Customization and efficiency: much of the power and usefulness of AR would be wasted if these systems were not flexible enough to be used in a wide range of different applications and processes. AR visualizations can easily be adopted for multiple functions and in a variety of conditions. Easy and intuitive to use, AR is a technology that helps workers and employees solve problems more easily, thus increasing their productivity.

These technologies greatly enhance training effectiveness and improve maintenance efficiency.

FAQs about AR in Maintenance

How is augmented reality used in maintenance?

Augmented reality (AR) is used in maintenance to provide technicians with real-time, contextually relevant information overlaying their physical environment. This can include visual instructions, schematics, and data about equipment, enabling more efficient and accurate troubleshooting and repairs.

How is augmented reality helping in maintenance?

Augmented reality assists in maintenance by offering technicians an interactive visual aid. It enhances their ability to identify, diagnose, and resolve issues with machinery or equipment, often leading to faster and more precise maintenance tasks.

What are 3 ways virtual reality or augmented reality can help areas in training and maintenance?

Virtual reality (VR) and augmented reality (AR) can aid in training and maintenance by: Providing immersive simulations for realistic training scenarios; Offering visual step-by-step guides for complex procedures; Allowing remote experts to provide real-time guidance through AR overlays.

These technologies greatly enhance training effectiveness and improve maintenance efficiency.