Toyota’s Two-Pronged Approach to IIoT

Toyota's investment in the Industrial Internet of Things (IIoT) is characterized by a strategic, two-pronged approach that balances long-term digital transformation initiatives with smaller, immediate-impact projects. This method not only drives substantial technological advancements but also empowers employees and maximizes

Navigating Regulatory and Technological Shifts in IIoT Security

The Industrial Internet of Things (IIoT) has revolutionized manufacturing, offering unprecedented connectivity and efficiency. However, this connectivity brings significant cybersecurity challenges. As manufacturers integrate IIoT into their operations, understanding and navigating regulatory and technological shifts becomes essential for maintaining robust

Low-Code Tools Empower Shop Floor Workers and Improve Efficiency

In the dynamic world of manufacturing, complexity, and rapid changes present significant challenges. Innovative solutions such as low-code tools and open-source software are transforming the industry, making it more efficient and adaptable. This article explores how these technologies reduce complexity,

From Pilot to Plant-Wide: Ensuring Scalable AI Solutions in Manufacturing

In the rapidly evolving manufacturing sector, digital transformation is not just a trend but a necessity. Leveraging technologies such as AI and machine learning (ML) can lead to significant improvements in efficiency, quality, and decision-making. However, the success of these

Generative AI: Bridging the Knowledge Gap for Manufacturing Personnel

Generative AI can make AI insights more accessible to shop floor operators, allowing them to make better decisions without having to understand complex data or algorithms. For example, generative AI could help operators understand what the next best action is to

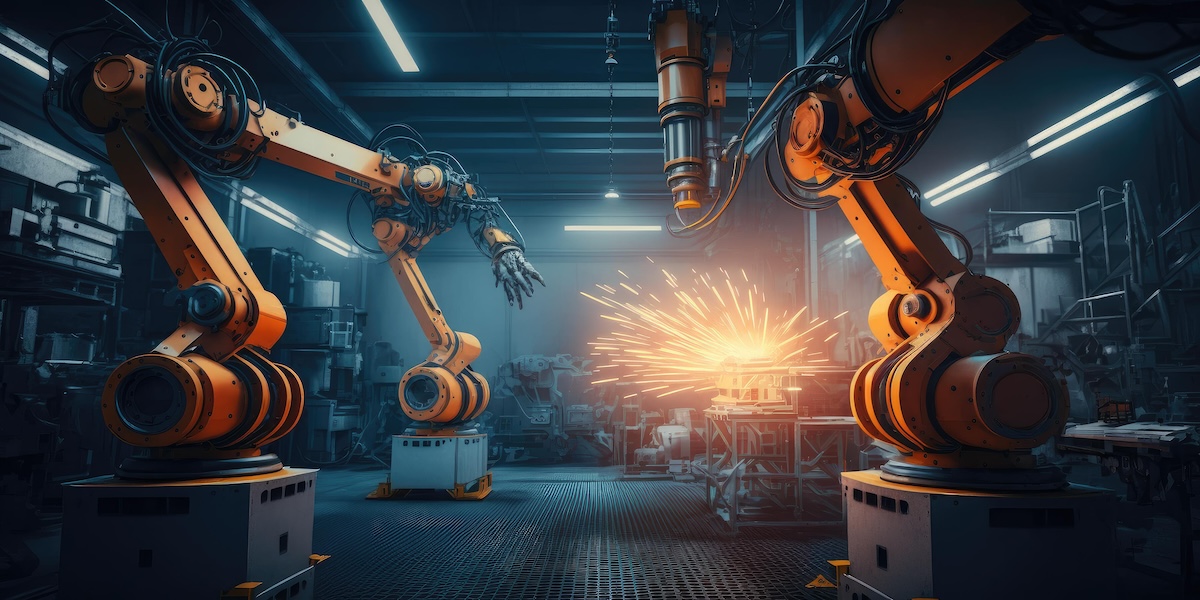

Harnessing IoT and Time Series Data to Revolutionize Manufacturing

The recent “Navigating the Data Tsunami: The Rise of IIoT Sensors in Industry 4.0” session at IIoT World Manufacturing Days highlighted insights into the transformative power of time series data and advanced data analytics in manufacturing. This follow-up interview delves

The Age of Accuracy: How Smart Manufacturing Is Redefining Unbiased, Efficient, and Sustainable Factory Processes

The advent of smart manufacturing promised higher visibility into factory operations and fast data analysis. Today, it’s safe to say what the industry has achieved has gone way beyond these expectations. The market is showing immense progress and a positive

Revolutionizing Precision Manufacturing: How Node-RED Transformed Abrasive Technology

Discover how Abrasive Technology, a leader in super-abrasive tooling and coatings, revolutionized its manufacturing processes with Node-RED. This case study delves into the challenges, solutions, and impressive results achieved by integrating this versatile low-code tool. Download the full case study

What is a Unified Namespace and How Does it Work in Manufacturing?

A unified namespace (UNS) provides a single point of access for all manufacturing data within an organization. It aggregates data from various sources like orders, historical records, telemetry, and execution information. Instead of functioning as a single version of the truth, a UNS