Avoiding the ‘watermelon’ effect in the process industry

Have you ever heard of the “watermelon effect”?

What exactly is the watermelon effect?

The watermelon effect is what happens when the metrics appear ‘green’ suggesting that everything is under control, and yet digging below the surface will readily reveal signs of ‘red’ indicating signs of ill-health in the arrangements to prevent major accidents.

The major accidents in 2005 at Texas City and Buncefield marked a watershed for the global process industry, with general agreement that process safety was not the responsibility of the technical safety department. The crucial role of senior leadership was recognized as vital to developing an effective process safety culture throughout the organization. Another key finding was the need for effective process safety metrics to be gathered and used to drive improvements, to achieve similar levels of improvement that have been achieved with occupational health and safety.

Reflection on the improvements made

Over a decade has passed since these high-profile accidents and now is a good time to reflect on the improvements made and whether the momentum for change has been maintained. Senior management attention for ‘continuous improvement’ in process safety could easily be distracted by a belief that the issue has been resolved. This raises a crucial question about when the next Texas City or Buncefield type accident will occur, and whether your business is doing everything possible to avoid the existential threat that such an accident could present.

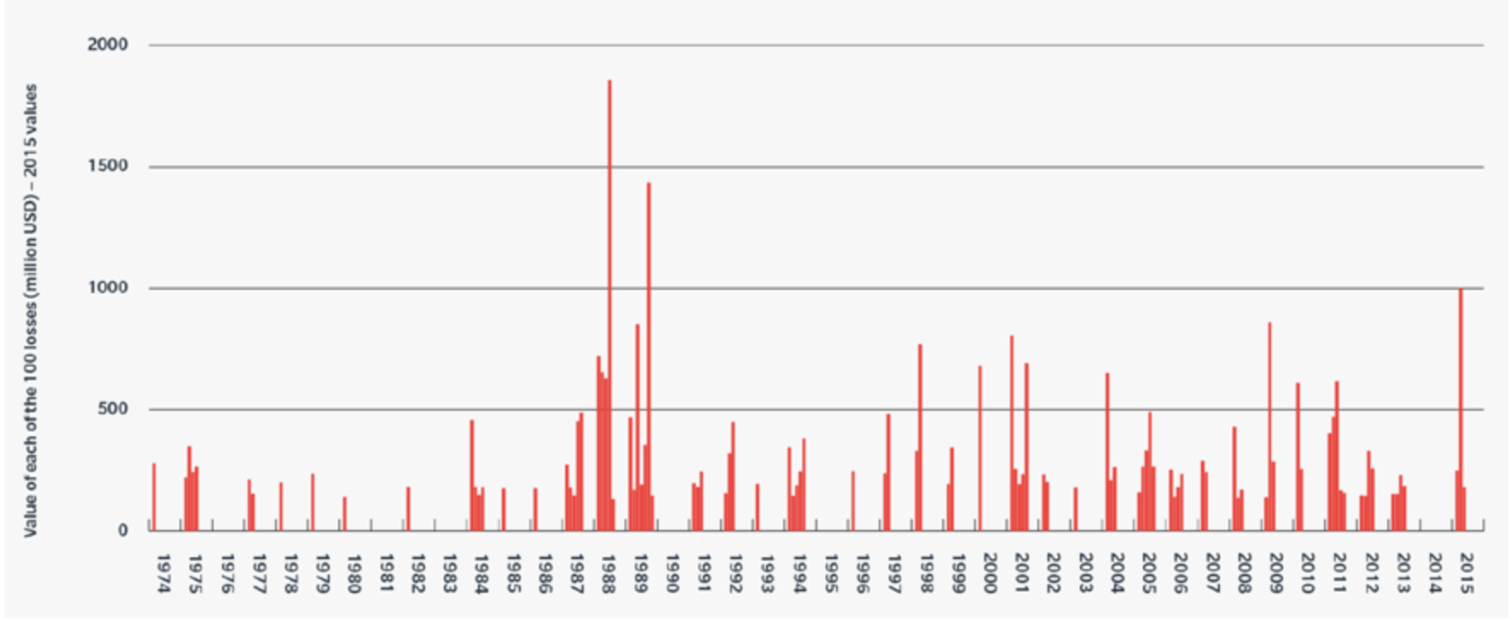

The graph below shows research by the Insurance company Marsh on the 100 largest losses in the hydrocarbon industry from 1974 to 2015.

Distribution of the 200 largest losses by year – source: Marsh Research

This shows that large losses have continued in the industry after 2005 at a fairly consistent rate, with an apparent upturn in 2015 that could speculatively be linked to the drop in oil prices affecting safety performance in this sector.

“Avoiding the ’watermelon’ effect” white paper

“Avoiding the ’watermelon’ effect” white paper will present findings from analysis by ABB following a recent process safety event, attended by senior process safety professionals, and data gathered during recent ABB webinars. It will introduce the concept of the ‘watermelon’ effect, where metrics appear ‘green’ suggesting that everything is under control, and yet digging below the surface will readily reveal signs of ‘red’ indicating signs of ill-health in the arrangements to prevent major accidents.

This white paper is intended to provoke discussion within the process industry on the dangers of complacency during periods when major accidents are not in the headlines, and to challenge senior management to seek assurance that process safety risks are being continuously lowered.

Key topics of this “Avoiding the ’watermelon’ effect” white paper:

- How to avoid the ’watermelon’ effect

- How to maintain a healthy level of unease

- How strong is the ’watermelon’ effect perceived by senior process safety professionals

- Greatest challenges in process safety

- Process safety metrics

We would love to hear your feedback on the ideas in this paper and about your own related experiences.

This is an excerpt from the “Avoiding the ‘watermelon’ effect” white paper, written by Graeme Ellis and Conrad Ellison.

Graeme Ellis is a Principal Lead Consultant with ABB Consulting with 35 years’ experience in the process industry, now specializing in process safety for major hazard installations. He is a Fellow of the IChemE and initially worked as a process engineer in design for MW Kellogg and Hercules before gaining operational experience and training as a hazard study leader with ICI. Since 1994 Graeme has provided PSM consultancy services in all sectors of the process industry, specializing in PHA revalidation for existing operations. He is a member of the UK Energy Institute Process Safety Committee, and completed an update of EI guidance on Inherent Safety in Design in 2014.

Conrad Ellison is a Fellow of the Institution of Chemical Engineers and a chartered environmentalist with 28 years of process engineering and process safety experience. He has supported numerous organizations across the process industries with their COMAH safety reports and has extensive hazard study experience majoring on HAZOP and Process Hazard Review (PHR) studies across the chemicals, petrochemicals, pharmaceuticals, power and oil and gas sectors. He also advises and supports companies on aspects of PSM.

FAQs about the watermelon effect

What is the no watermelon effect?

The “no watermelon effect” refers to a situation where an organization’s reported performance metrics or key performance indicators (KPIs) appear green or positive on the surface, much like the exterior of a watermelon, but internally, they are red or negative. It indicates a discrepancy between what is presented and the actual reality, potentially masking underlying issues or problems.

What is the watermelon effect safety?

The “watermelon effect safety” describes a situation where safety metrics or indicators appear satisfactory at a glance, often indicated by green or positive indicators, but upon closer inspection, safety issues or risks are discovered. It highlights the danger of relying solely on superficial safety measures and the importance of a thorough understanding of safety performance.

What is the watermelon metrics effect?

The “watermelon metrics effect” refers to the phenomenon where metrics or performance indicators seem positive on the surface, indicated by green or positive colors, but they belie underlying problems or negative performance when examined more closely. This term emphasizes the need to ensure that metrics accurately reflect the true state of affairs rather than just presenting an optimistic facade.