For Industrial IoT success, look beyond your factory walls

The architecture for Industrial IoT (IIoT) is largely understood. Sensors gather data. Networks orchestrate the data. Computation processes the data and analysis of the data to make it usable and actionable. However, one of the most significant challenges for manufacturers looking to create a connected factory is where to start their project. The next question becomes knowing the essential elements for success.

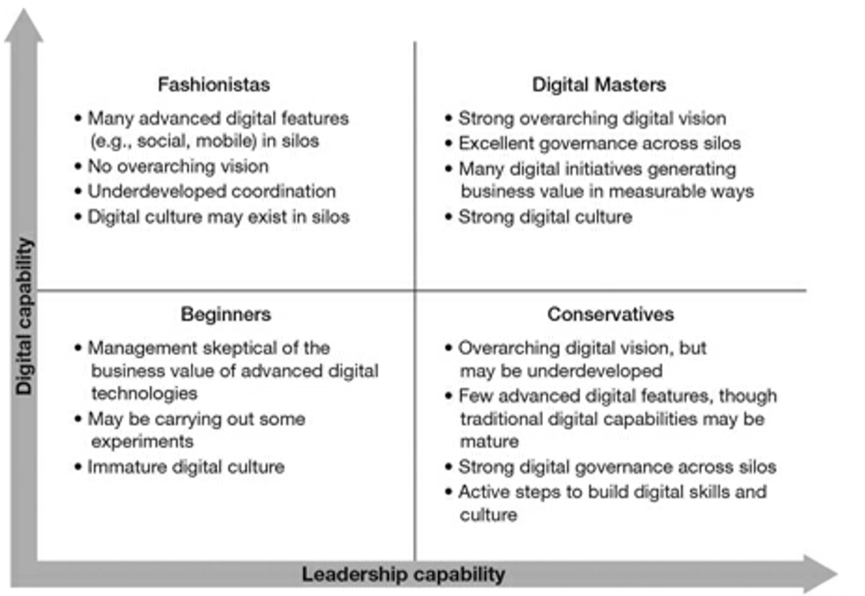

The problem isn’t unique and is an issue across many industries. In the book Leading Digital, authors George Westerman, Didier Bonnet, and Andrew Macafee developed a framework that helps identify where companies are on their journey in aligning both their investment and leadership within digital initiatives.

Source: http://www.thedigitaltransformationpeople.com/channels/the-case-for-digital-transformation/digital-mastery.

Based on their research, the authors noted that there is effectively an axis for where companies drive leadership capabilities and where their digital capabilities lie. Four levels define where organizations currently sit in their execution and investment:

- Beginners: These are organizations in the very early stages of adopting digital and IIoT. They may have engaged in small pilots or dabbled in some areas, but have not made investments to make IIoT a core part of their business or culture.

- Fashionistas: These organizations have a digital culture in pockets. They may have invested in digital applications and IIoT, but have not aligned leadership in implementations and are struggling to scale their investment and operationalize their digital efforts.

- Conservatives: These organizations have aligned a vision and a governance model, but lack wide-scale investment in digital initiatives.

- Digital Masters: These are the groups that have aligned both the business side and the application side of their investments. This structure includes culture, vision, and governance.

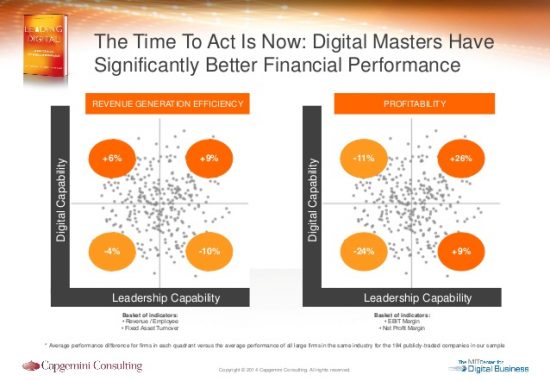

The benefit of moving up and to the right becomes clearer when viewing revenue generation and profitability across this framework. On average, companies that become more digitally capable are more efficient at revenue generation and profitability. The sample of publicly traded companies by Westerman, Bonet, and Macafee breaks down as follows:

Source: https://www.slideshare.net/rbouter/didier-bonnet-oracle-open-world-presentation-on-leading-digital-capgemini-consulting-digital-transformation

Digital masters on average see a 9% increase in revenue efficiency and a 26% increase in profitability when compared to their peers. When reviewing the numbers in the chart above, it’s easy to see why organizations are driven to become digital masters. For manufacturers, however, the current state is that many are stuck in that beginner’s quadrant, with some good IIoT initiatives but inertia in moving along on the digital transformation journey.

Industrial IoT: Breaking Through

Manufacturing is a more conservative business when it comes to taking on projects, compared to other industries. Initiatives must have clear ROI, minimal impact on current operations, and be able to scale across an organization. “Science projects” are not well-received on the factory floor.

The other reality is that resources are constrained, as companies have to focus on staying competitive in increasingly fast-changing markets. Becoming a digital master is very possible, but the reality is that it often takes help from someone who understands both digital capability and leadership capability.

These resources usually aren’t available—or don’t exist—within industrial organizations. For manufacturers, this means finding a partner that understands how to coordinate business models to address security, reduce downtime, increase overall equipment effectiveness (OEE), and bring new products to market faster. This understanding is where we can help having a proven track record of assisting manufacturers achieve digital mastery. The key is building that digital foundation, which should include:

- Assessment of current environment

- Planning a solution using validated architectures

- Solution design

- Solution deployment

- Care and support

Unlocking value from your digital investment is the key to driving increased revenue and profitability. Combining leadership and capability will position companies for a long-term strategy that optimizes into the future. I invite you to check out the following information to learn how our Services team can help move you toward becoming a digital master.

Further reading: Avoiding the ‘watermelon’ effect

This article was written by Eric Ehlers, Marketing Manager at Cisco. Eric joined Cisco in 2016, taking responsibility for marketing in the manufacturing vertical. He was previously Director of Marketing at Belden, where he worked with the Industrial Networking and Connectivity, Enterprise Connectivity and Cybersecurity business units. Originally the article was published here.

This article was written by Eric Ehlers, Marketing Manager at Cisco. Eric joined Cisco in 2016, taking responsibility for marketing in the manufacturing vertical. He was previously Director of Marketing at Belden, where he worked with the Industrial Networking and Connectivity, Enterprise Connectivity and Cybersecurity business units. Originally the article was published here.