New IIoT Case Study with Wiscon Products

Since 1945, Wiscon Products of Racine, WI has produced quality precision parts for the aerospace, medical, energy, automotive, construction and power industries as well as many others. Along the way, Wiscon’s innovation and commitment to quality has resulted in awards such as the 2014 Manufacturer of the Year and twice as the Future 50 winner for recognizing local, fast-growing entrepreneurs.

Since 2018, Wiscon has utilized MachineMetrics at their facility in Racine to further improve their efficiency and Overall Equipment Effectiveness. The objective with MachineMetrics was to closely align with core goals of process improvement, reduced downtime and increased equipment utilizationto better service their growing client base and gain full control of the data available to them.

“The biggest change has been in efficiency. Specifically, being able to visualize the data and act upon it in real-time. We didn’t have a lot of historical data and what we did have could only be addressed reactively. And planning and scheduling was a top priority. Without accurate data, planning and scheduling were difficult. We had spent over $16 million on equipment but still felt like we were running at capacity. Our production department was always “busy”; there were gaps in the data and not being visible in real-time caused a lag.” Torben Christensen, President/CEO, Wiscon Products

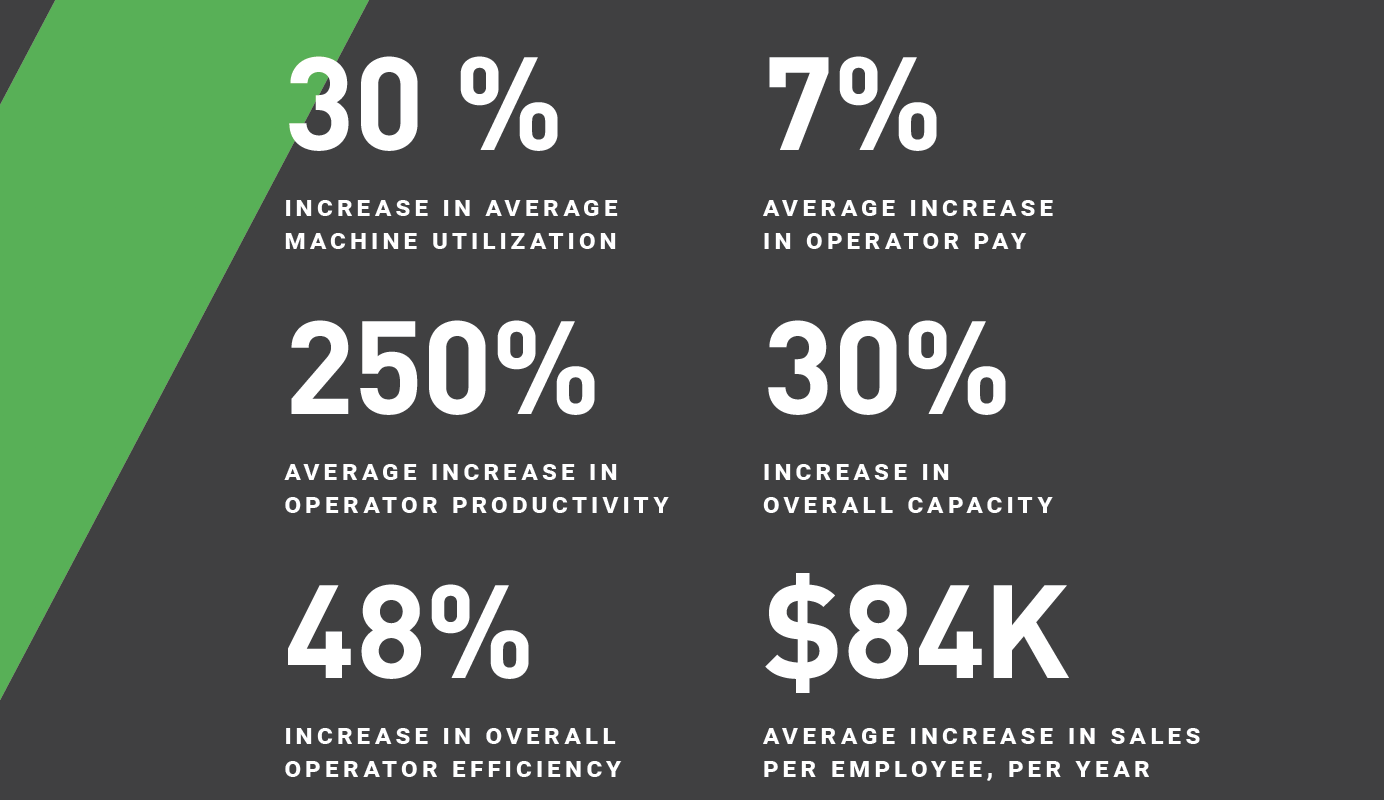

Download this new case study by MachineMetrics as it details all of the fantastic gains that Torben Christensen, President/CEO of Wiscon Products, was able to see after implementing MachineMetrics, including:

- Data Accuracy

- Increased Operator Productivity

- Accurate Production and Utilization Monitoring

- Increase in Overall Capacity

Graham Immerman, the author of this resource, is Director of Marketing for MachineMetrics, a venture-backed manufacturing analytics platform. Graham has quickly become an authority on digital transformation and the application of IIoT technology for the manufacturing industry. An accomplished leader and experienced start-up veteran with an integrated background in digital, social, traditional, account-based marketing, growth strategies, and business development.