Report on State of IIoT Adoption and Maturity in Three Industries

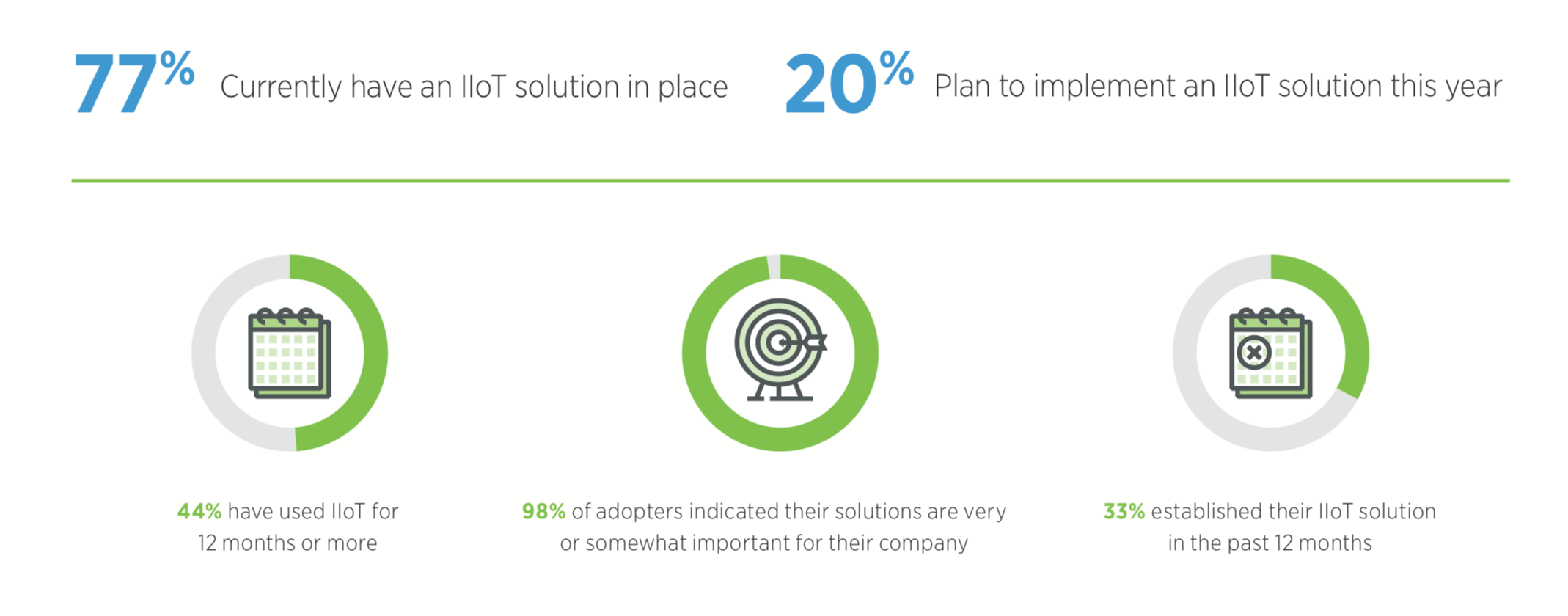

A survey of senior-level, experienced Industrial IoT decision-makers and influencers in the manufacturing, oil and gas (O&G), and transportation industries confirms that IIoT has progressed beyond hype to widespread use. Eighty six percent of participants in the Bsquare 2017 Annual IIoT Maturity Survey have adopted IIoT solutions and 84% believe their solutions are very or extremely effective.

Almost all respondents believe that the technology provides a significant or tremendous global impact on their industry and that setting clear business objectives prior to deployment, such as better managing devices, increasing production volume, or reducing operating costs, is an important driver of deployment maturity and return on investment (ROI). Fewer than 2% of respondents are not considering an implementation within the next 12 months.

IIoT Adoption by Industry: Survey Results

The survey results validate that Industrial IoT adoption is a maturity progression where companies realize increasing levels of benefit as they expand from basic machine connectivity to advanced approaches including analytics, automation, and edge computing. Current adopters overwhelmingly cite device health as the top business challenge they are addressing followed by logistics, operating cost reduction, and increasing production volume. In spite of high adoption rates, only 54% of all the devices deployed in the adopter organizations are IIoT technology-enabled, leaving ample opportunity for growth.

As organizations see the increasing benefits of implementing IIoT, 73% of adopters say their investment will increase in the next 12 months, with transportation and manufacturing leading O&G. As the result of this continued investment, respondents expect to see increases in achievement of business priorities such as automation and real-time monitoring over the next year.

Impact on Adoption of Industrial IoT in Manufacturing

The manufacturing industry has a long history of automated machines and systems. IIoT is part of larger Industry 4.0 and digital transformation efforts to help connect critical assets, extract data, and improve factory operations.

Current Industrial IoT Adoption

Manufacturers are strongly committed to IIoT and place a very high level of importance on it for their organizations.

Solution implementation is based on business needs. Seventy-six percent have chosen a cloud-based solution compared to 24% for on-premise. This preference is likely driven by the ease of deployment offered by cloud-based solutions.

Industrial IoT Business Maturity

Manufacturing respondents indicated their use of the IIoT adoption stages:

- Device connectivity and simple data forwarding: 67%

- Real-time dashboards and monitored activity through constant data stream: 62%

- Advanced analytics, such as machine learning, cluster analysis, and artificial intelligence, from data scientists: 47%

- Automated simple, single-step actions such as service-ticket requests: 32%

IIoT ROI increases once businesses apply advanced analytics, such as machine learning, to identify data correlations in real-time, and automation of processes such as repair tickets. Because the use of these two stages lags behind device connectivity and real-time monitoring, manufacturing companies have significant opportunity to advance their IIoT capabilities for greater future impact. When asked how large of an impact IIoT technology and related solutions will have on their industry in the future, 90% of respondents said it will have either a significant or tremendous global impact.

Operational Impact of Industrial IoT

Current adopters were asked to cite the top business challenges they were targeting with their IIoT solution. Logistics-related items and machine health topped the list, indicating that maintaining and optimizing equipment and operational parameters are closely tied to supply chain efficiency.

In terms of effectiveness of their IIoT solutions, 84% of respondents felt that their IIoT solutions are either very or extremely effective.

Future Outlook

Given the positive operational and organizational impacts cited by respondents, it is not surprising that they plan to continue their investment into IIoT, and the majority plan to invest more. Within the next 12 months, 78% plan to increase their investment and 20% plan to spend about the same as the past 12 months.

This is an excerpt from the report. A copy of the complete study can be downloaded here.