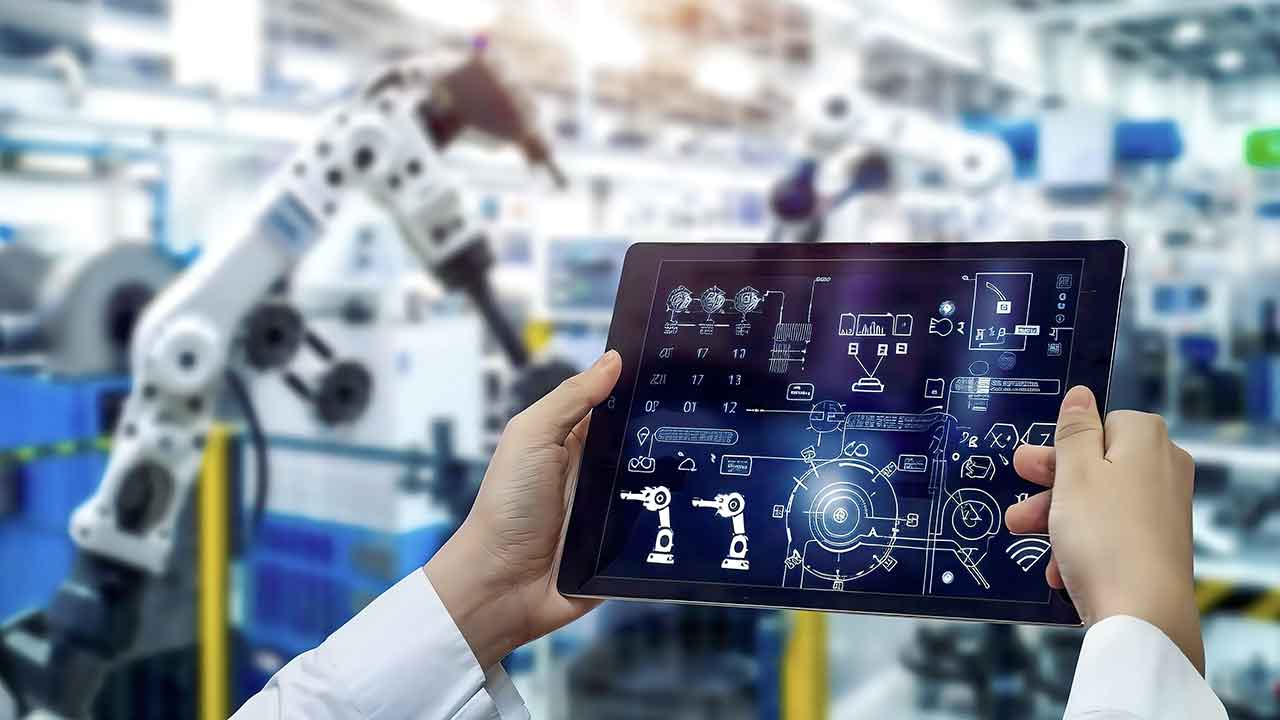

The role of Industrial Analytics in driving Manufacturing Transformations

As global competitive pressures have driven changes and higher expectations for manufacturing organizations, enterprise technology in manufacturing must respond at an accelerated pace today. Largely the result of fundamental changes enabled by transformative technologies, new and novel opportunities for industrial organizations are looming. This provides the capacity to leverage the role of industrial analytics and use operational data and systems for new opportunities, as well as allowing operations to be more competitive in their markets and more responsive to their customers.

Industrial Analytics Insights

The widespread use of smart sensors and devices and the acceleration of interest and adoption in industrial IoT and digital transformation initiatives have spurred innovation throughout the entire manufacturing ecosystem. Research by ARC Advisory Group highlights just how far manufacturers have come over the past few years, and where they are headed.

More about Top Use Cases for Manufacturing Analytics

Key takeaways from this white paper include:

- Data being generated in the manufacturing industry is increasing – at the edge, on-premise, and in the cloud

- Industry 4.0 (some call it Manufacturing 4.0) cyber-physical systems provide an opportunity to drive business transformation

- A digital innovation foundation can accelerate use cases that drive transformational outcomes and enable manufacturing personnel to become agents of change and bridge the IT/OT gap

- The 4Ms offers opportunities to drive new insights and transformative use cases that can become a source of new competitive advantage

Download “Take Manufacturing to The Next Level with Industrial Analytics” white paper written by ARC Advisory Group for more insights. This white paper is sponsored by Hitachi Vantara.

For more resources on IIoT/analytics on our website, click here.

Industrial Analytics FAQs

What is industrial analytics?

Industrial analytics refers to the use of advanced data analysis, such as machine learning, artificial intelligence, and predictive analytics, to gain insights in order to better optimize industrial operations. Industrial analytics involves collecting and analyzing data from various sources, like machines, sensors, and production systems, to identify patterns and trends, optimize processes, and improve product quality.

What is the difference between enterprise analytics and industrial analytics?

While enterprise analytics focuses on analyzing data from various business functions, such as ales, marketing, and finance to improve performance, industrial analytics is focused on optimizing industrial processes to improve product quality focusing on data from manufacturing, production, and supply chain operations.

What are the core components of industrial analytics?

The core components of industrial analytics typically include data collection, data preparation, data analysis, and visualization. Industrial analytics requires collecting data from various sources, such as sensors, machines, and production systems, and preparing it for analysis by cleaning and processing it. Data analysis involves using advanced techniques to identify patterns, predict outcomes, and optimize processes. Finally, visualization techniques are used to communicate insights and facilitate decision-making.

What are some use cases of industrial analytics?

There are many use cases for industrial analytics, including:

- predictive maintenance – uses analytics to monitor machines and predict when maintenance is required, reducing downtime and costs;

- quality control – involves using analytics to identify and prevent defects, improving product quality;

- process optimization – involves using analytics to identify bottlenecks and inefficiencies in production processes, reducing waste and improving productivity;

- supply chain optimization – involves using analytics to optimize inventory levels, reduce lead times, and improve delivery performance.

Sorry, the comment form is closed at this time.

Pingback: The role of Industrial Analytics in driving Manufacturing Transformations – IoT – Internet of Things