A Decade of Industry 4.0 – Topics: The Promise, The Reality and what comes NeXT?

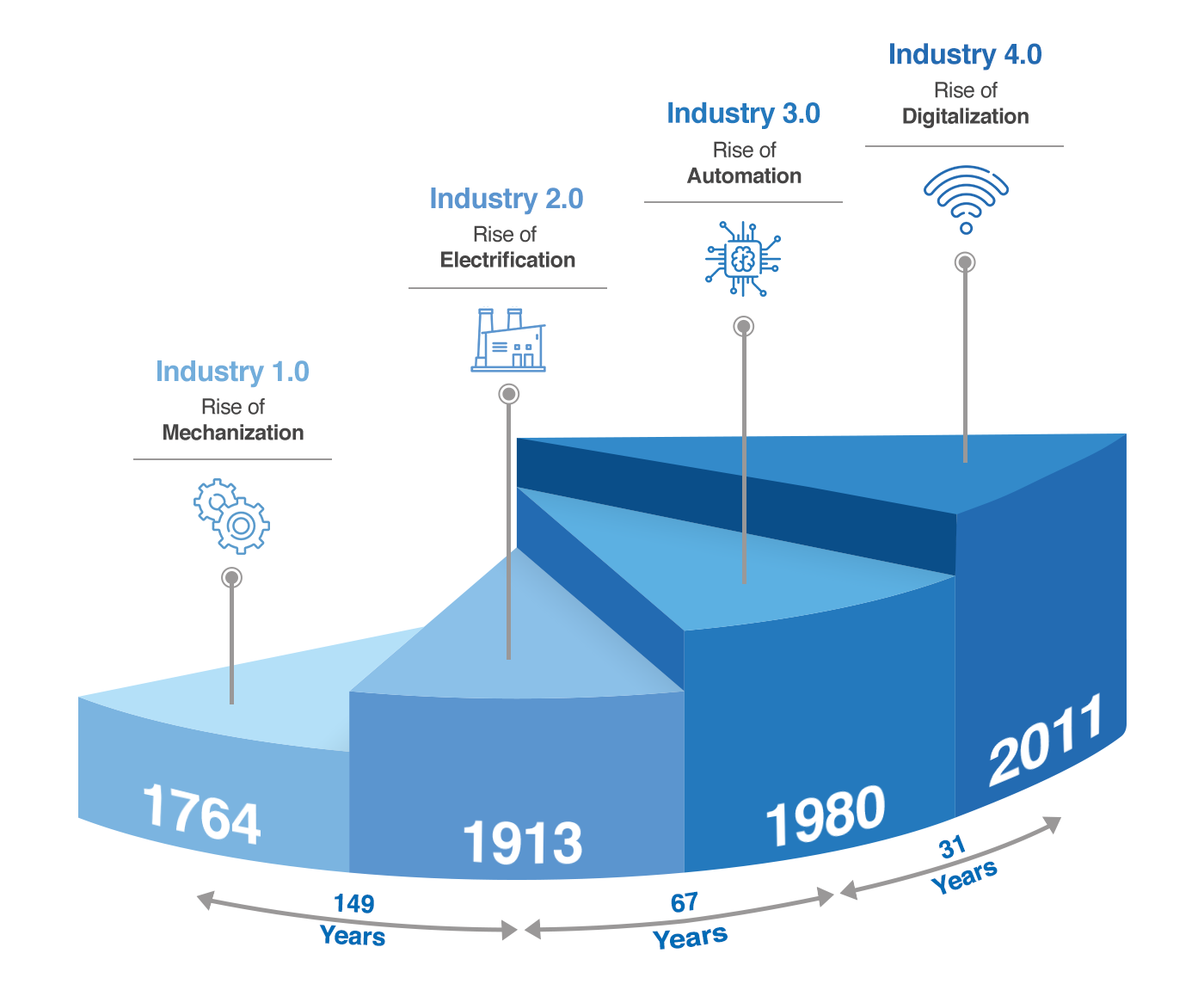

Four major industrial revolutions have occurred in the last few centuries with each revolution contributing to enhanced productivity and operational efficiency of the manufacturing process. Transition time between these revolutions has decreased drastically (Figure 1). As newer technologies emerge and business priorities change, the time between the last revolution, Industry 4.0 (I4.0) and the next will drop even more.

Adoption of Industry 4.0 technologies

The adoption of Industry 4.0 technologies was a turning point in the history of the human-machine relationship. Since 2011 when I4.0 arrived, it has evolved the fastest on the back of advances in technologies, such as cyber-physical systems, IT/OT convergence, AI/ML, Blockchain, and AR/VR.

The COVID-19 pandemic was a litmus test for organizations to understand the impact that Industry 4.0 adoption could put on their business processes and personnel policies. Studies show that businesses that implemented I4.0 technologies before the pandemic were “better positioned to respond to the crisis.” Also, 96 percent of organizations with mature I4.0 implementations (at least some use cases scaled across locations) reported “a stronger ability to handle the crisis.”

Industrial Revolution Phases

The new normal is expected to be driven by technology, making businesses more resilient, human-centric, and sustainable. By empowering the workforce and placing worker well-being at the core of the production processes, emerging technologies are expected to expand their objectives from efficiency and productivity to include contribution of industry to society. To deliver evolving business expectations, I4.0 must undergo an evolution in being better equipped for these new realities and companies attached to I4.0 as a benchmark would quickly get onto a lagging path of evolution.

What has Indystry 4.0 achieved, and what is it missing?

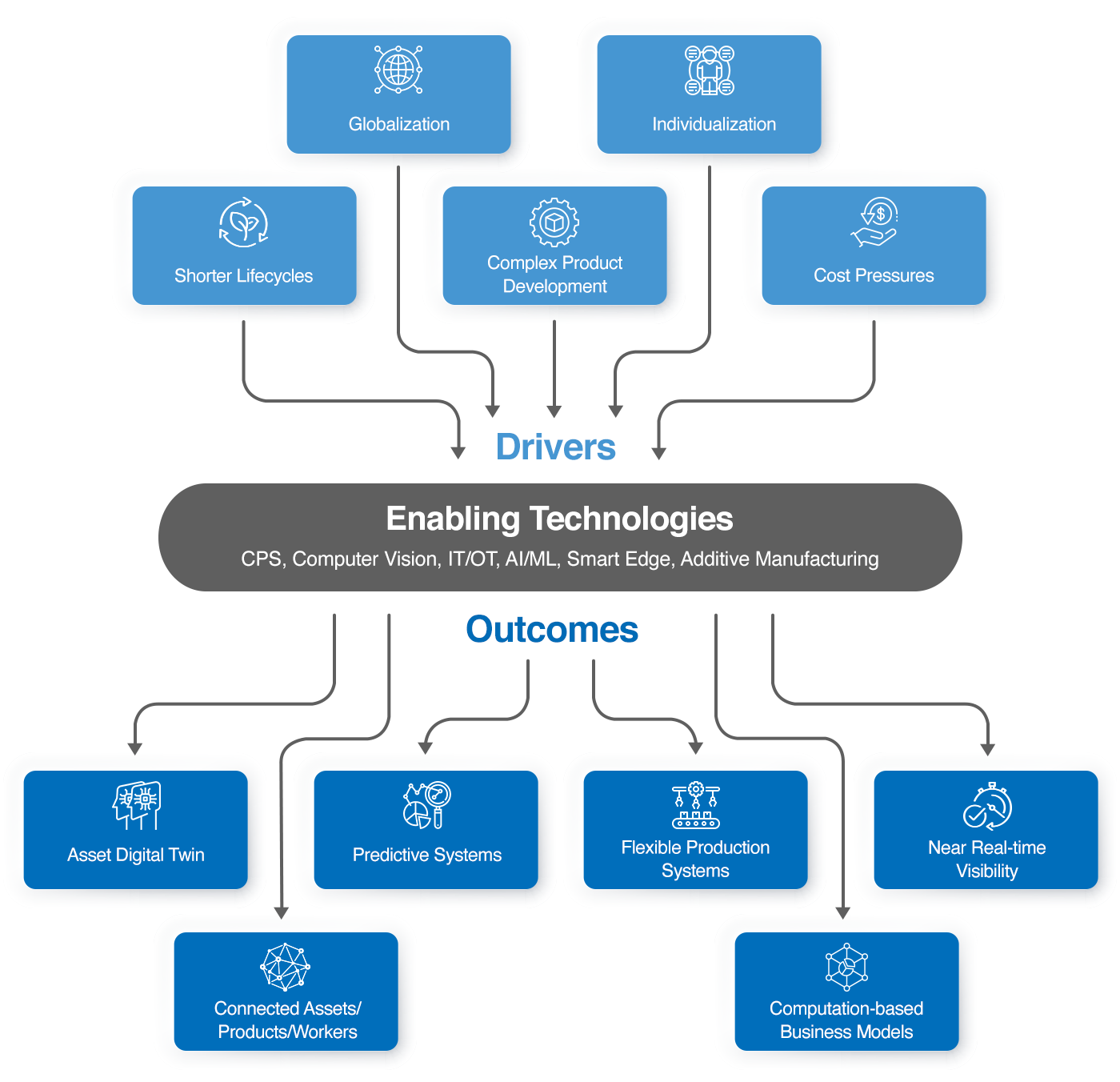

I4.0 was a construct in the cyber-physical production space with a heavy reliance on large-scale adoption for success. With the manufacturing industry directing the wave of adoption, outcomes like boosting efficiency and reducing costs went mainstream. The result was a definitive change in how manufacturing worked. These efforts resulted in significant gains for enterprises.

Figure 2: Drivers, Technologies and Outcomes of Industry 4.0 Journey

However, as businesses’ level of understanding matured, newer aspirations transpired. Frequently changing market conditions and pandemic-driven disruption in supply chains generated disruptive business models and the desire for sustainable business processes. I4.0 needs to be leveraged with greater intensity to lead to the realization that there is still more that needs to be done.

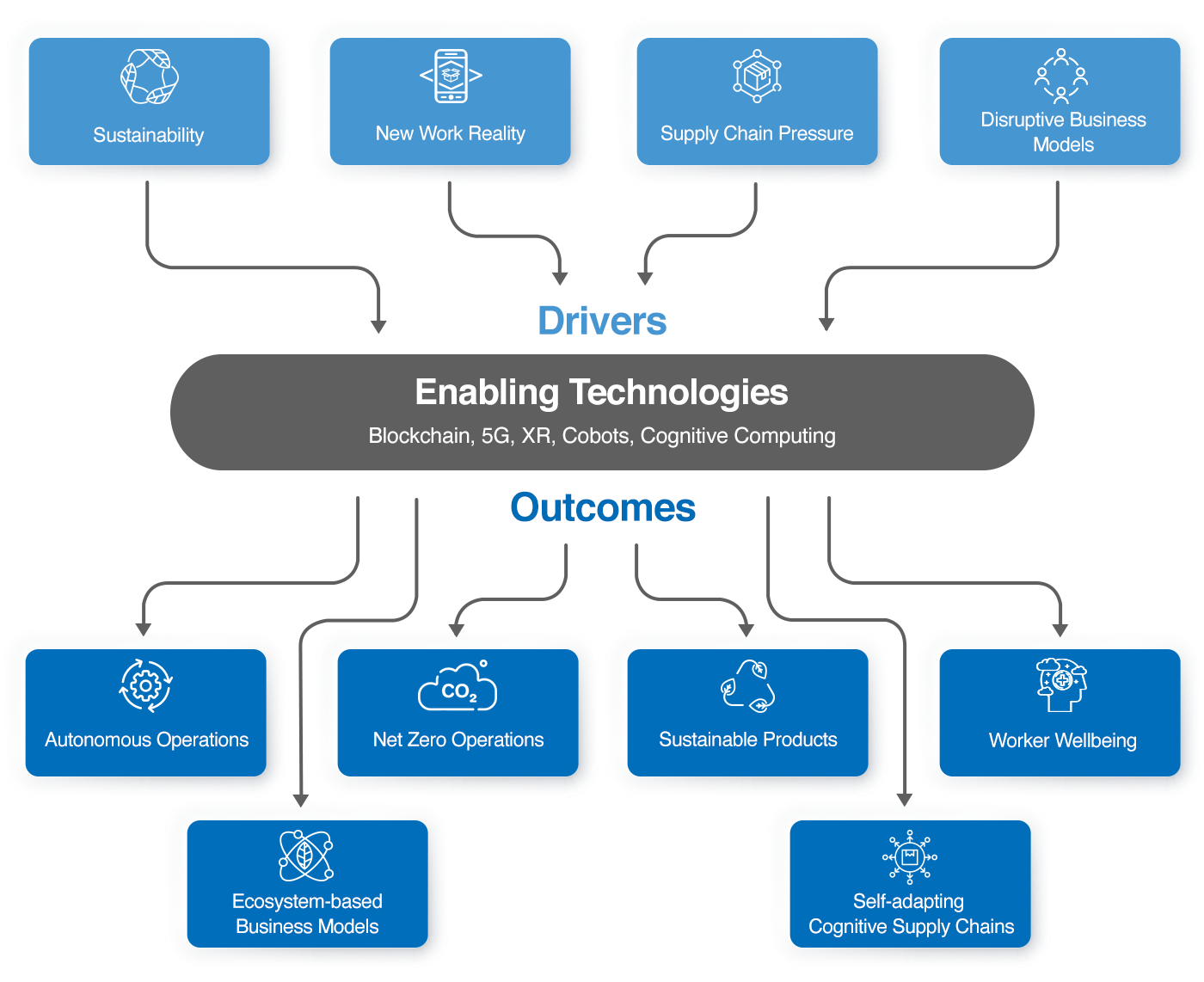

As businesses shift their focus from operational excellence to value-centric, purpose-driven business models, they are on the brink of transcending to a new ecosystem-based phase called, Industry NeXT by HCL Technologies.

Key Tenets for Industry NeXT

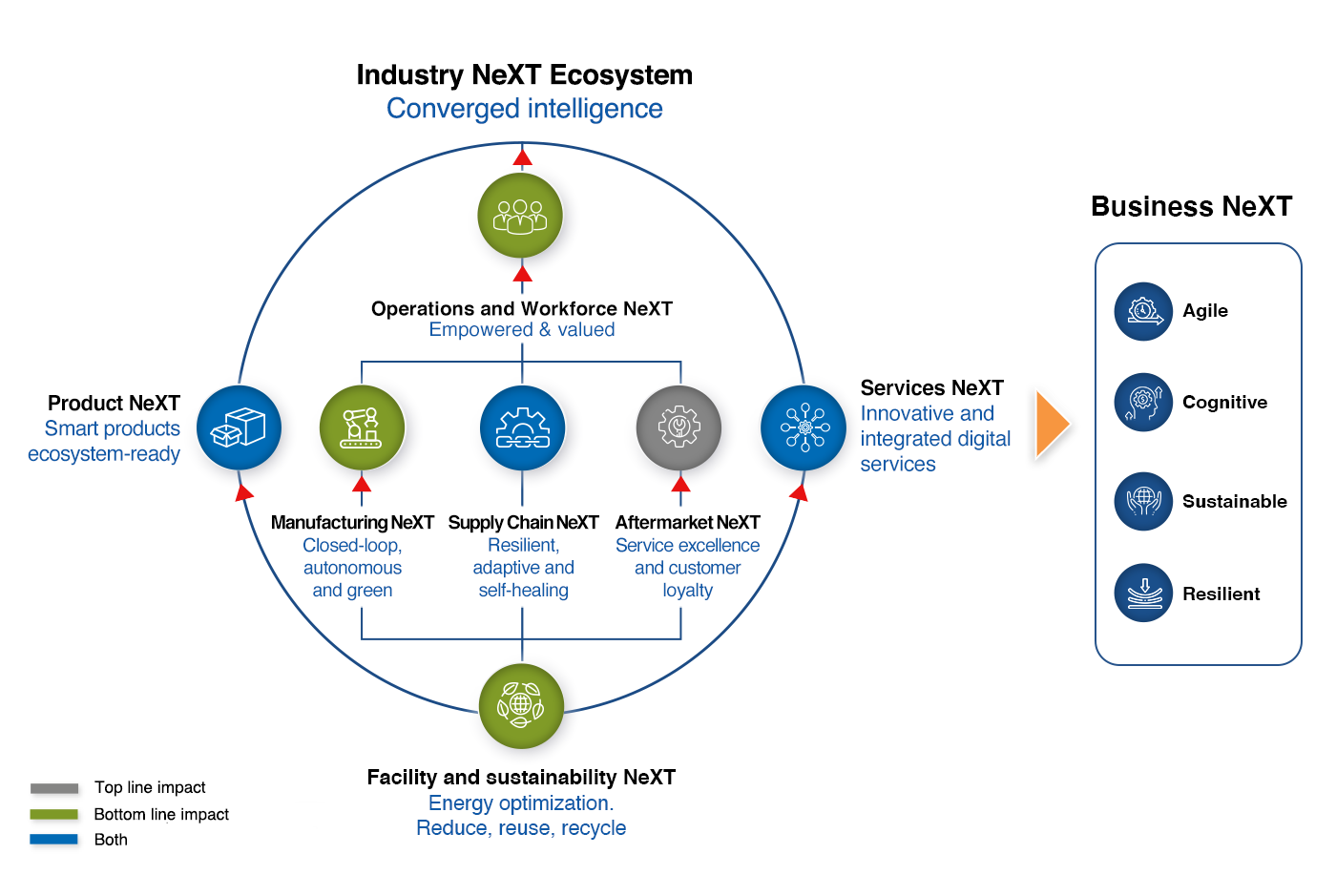

Industry NeXT builds on the I4.0 foundation is a transformational framework and forms a cognitive ecosystem of connected experiences, resilient operations, and blend of physical and digital products and services. It enables the creation of contextual insights from an ecosystem of stakeholders, operations, and facilities—all connected by a digital thread that allows businesses to create smart products and digital services, resilient operations, and sustainable processes.

Figure 3: Drivers, Technologies and Outcomes for Industry NeXT

Key Topics for Industry 4.0 Technologies Future

The key transformative forces that drive businesses to prepare for the future and examine their effects on the industry:

Sustainability

Climate change, geopolitical shifts, emergence of disruptive technologies, aspiration to achieve net-zero operations, and other trends make the Environmental, Social, and Governance (ESG) strategy even more important. Technology can reduce operating costs through improved internal energy management waste and carbon footprint reduction. A multinational plant equipment manufacturer headquartered in Switzerland drives its sustainability objectives by reducing energy consumption and wastage across the manufacturing value chain. With the help of image analytics, robotics, data insights, and AI/ML, the manufacturer met its sustainability goal of 30 percent reduced energy consumption and 30 percent waste reduction.

Lifecycle Value

The pandemic forced businesses to re-think the value generation process because of fluctuating demand patterns and a disrupted supply chain. Companies have responded by shifting from a product-centric to purpose-driven model to generate value. A European multinational aerospace corporation is simplifying its end-to-end managed services and enhancing the management of its special devices using a wide range of HCL’s connected services and solutions. As a result, the aerospace giant has reduced onboarding times by 30 percent, reduced device downtime by 25 percent, and simplified the management of 20+ device families.

Products and Ecosystems

Businesses need the ability to innovate and go-to-market faster to offer a higher degree of personalization and remain cost-effective. Above all, in the post-pandemic world, they also need to stay relevant in new market realities.

New Business Models

Post-pandemic, with the help of newer technologies, businesses are not only achieving new levels of process and cost efficiency but creating new revenue streams.A global kitchen equipment manufacturer utilized an ecosystem driven approach to create new revenue streams and a new service model enabling enhanced visibility into health and performance of their products in the field. This “Data as a Service” offering created insights and predictive health monitoring to improve overall customer experience. This created cost savings with remotely monitoring of assets across geographies and client locations along with reduced break-down visits.

What’s NeXT?

Economic value creation is rapidly moving beyond traditional value chains with the emergence of collaborative ecosystems—a stepping stone to growth, as they offer great opportunities to participants to create value in a more efficient manner. Industry NeXT by HCL Technologies maps this paradigm shift and helps businesses transcend toward a connected ecosystem in a quick, modular, and simplified way.

Industry NeXT brings homogeneity to the enterprise by taking stock of existing investments, identifying needs for digital continuity, and providing a blueprint that aligns with business objectives. The key transformation levers are:

- Intelligent integration of people, process, and technology

- Cyber and physical aspects of ecosystems

- Inclusion and collaboration of both internal and external stakeholders

- Horizontal integration with digital continuity from discover/define/design/source/build/test to manufacture/supply/experience/service/sustain

- Vertical integration where there is digital continuity from assets and employees to customers and consumers

- Lifecycle integration where there is digital continuity between the various stages/phases/states of the product or service from the time it is conceptualized to its state in operation, and then when there is an end of life when it needs to be salvaged or recycled

Figure 4: Industry NeXT

Embracing existing and emerging technologies across core operations to unlock more compelling possibilities is the way forward. It affirms the need to understand the impact that collaborative ecosystems can create and how they will become a key differentiating factor for generating value with a better trained workforce. When combined with greater adoption of next generation technologies, an understanding of manufacturing processes will be created that spans beyond productivity and becomes inclusive of sustainability, agility, and resilience. Find out How to Achieve More Sustainable Manufacturing Practices

NeXT is exciting. Get ready to unlock your business potential to make it more efficient, inclusive, meaningful, safer, and sustainable with Industry NeXT by HCL Technologies.

Here is the latest thought leadership piece authored by Sukamal Banerjee, Corporate Vice President, Industry Software Division and IoT WoRKS.

Originally it was published here.