Challenge: Tracking and Controlling Warehouse Inventory

To keep daily operations running smoothly at large plants, manufacturers typically employ a staff of maintenance workers who are solely responsible for repairing and replacing on-site equipment. This plant equipment is stored within warehouse facilities so components can be quickly retrieved when a maintenance issue arises. However, keeping track of parts and tools as they’re checked in and out of these storage facilities is a common challenge. Even with comprehensive inventory management systems in place, human error and employee theft can result in millions of dollars in lost inventory. One of the largest US poultry producers faced this challenge and tackled it head on.

Internal Audit Highlights Warehouse Losses & Inefficient Maintenance Processes

After conducting an audit of nine of its 23 maintenance storage facilities, the poultry company estimated it was losing between $1M to $2M in equipment per year at each location – representing a potential loss of $46 million dollars in unaccounted inventory. In addition to monetary losses, the company’s inventory tracking problem had a direct impact on plant production and employee productivity. When the equipment was misplaced or missing from a warehouse shelf, it resulted in a slowdown in production while the maintenance staff attempted to locate the missing equipment or waited for new parts to be delivered. Inconsistent maintenance work order procedures and lax physical security were making it nearly impossible for the company to effectively track and control its warehouse inventory.

Lack of Access Control and Visual Verification of Worker Activities

The company had an enterprise-wide inventory tracking solution in place but had used access control and physical security systems inconsistently across its different plant locations. At some warehouses, full-time personnel were on-hand to check work orders as the maintenance staff brought them in. But at other locations workers were given physical keys and unfettered, untraceable access to the warehouses. A lack of video cameras at most sites compounded the problem. Without video in place to track worker activity, inappropriate behavior and a lack of accountability were common. Beyond physical security issues, loose work order procedures made it easy for maintenance personnel to take shortcuts or circumvent check in and check out processes altogether. In some cases, workers were using old work orders to reduce the time it took to get the maintenance parts they needed leading to inventory errors, misplaced items, and employee theft.

In short, without access control mechanisms and video in place, work order policies could not be enforced, and improper behavior could not be proven.

The Solution: Video-Based Warehouse Loss Prevention from IVC

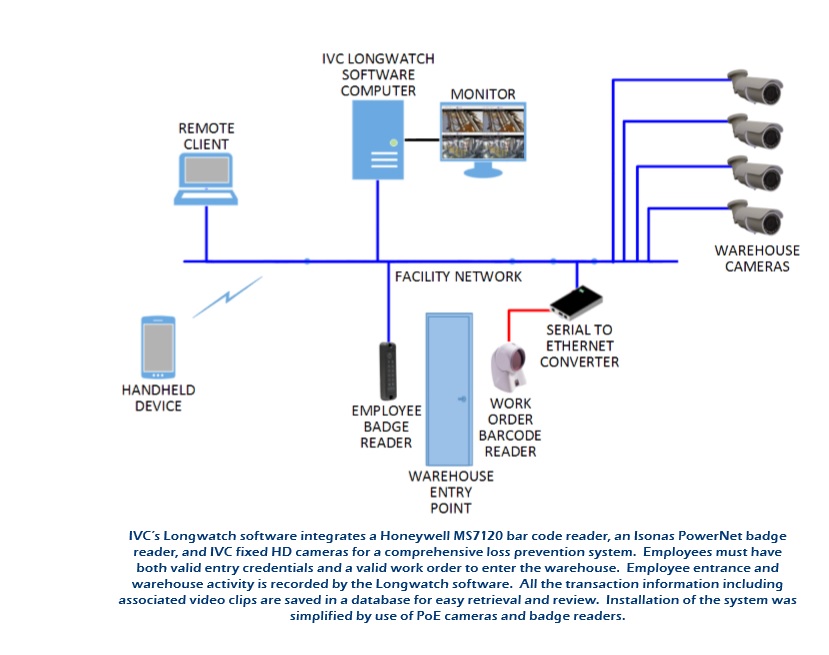

The company turned to IVC to provide a video-based warehouse activity tracking solution that delivers visual verification, access control, and inventory tracking in a single system. The solution combines IVC high-definition, IP, bullet video cameras and Longwatch camera management software with third-party access control devices and work order bar code scanners. IVC’s cameras produce broadcast quality video, even in low light conditions. The cameras are powered over Ethernet, making installation easy and inexpensive.

IVC’s Longwatch software is a powerful camera management platform that records video from each camera and automatically correlates it with data from the badge readers and bar code scanners. The result is an easy to use, searchable, event database that catalogs the time, location, employee ID, work order number, and a video record for every worker transaction– giving the company a wealth of information that saves time, money, and effort.

Deployed at three warehouse locations to date, the system has created a more efficient work order process and is positively impacting the company’s bottom line.

How IVC’s Warehouse Tracking System Works

IVC video cameras, badge readers, and bar code scanners are installed at the entrance of each warehouse and various locations inside the warehouses. When a work order is created, it is automatically assigned to a maintenance worker via the company’s SAP system. Each work order includes a unique bar code and list of components required for the repair. To gain access to the warehouse to retrieve the parts, the worker must scan both his employee badge and work order bar code. Inside the warehouse, additional cameras and badge readers located in different areas provide further access control. Each time a worker’s badge is scanned,

IVC’s Longwatch software captures detailed information about the transaction including the worker’s badge ID, operator order number, and a video snippet of the employee’s entry. This high-resolution video saved from the IVC HD cameras provides the opportunity for detailed pre- and post-event analysis of the employee transaction. If there is an inventory discrepancy, the site administrator can just click on an event in the Longwatch system to get accurate information about the work order transaction and play back a video of the maintenance worker’s movements and decisions.

The Results: Big Savings & Greater Worker, Production Efficiency

IVC’s warehouse tracking system has had an immediate impact on production efficiencies, worker accountability, and the company’s bottom line. For the first time, the company has a work order procedure in place that is easily enforceable. Workers cannot take shortcuts to get the maintenance equipment they need and must adhere to proper maintenance policies. The use of video and the fact that there is a record of all work transactions tied to individual employees has also curbed inappropriate behavior.

Recently, a $10,000 processing component went missing from one of the plant’s warehouses. The SAP system used for inventory tracking showed that the component should have been in stock and on the shelf, but it wasn’t. Using IVC’s Longwatch software, the Maintenance Repair Operations (MRO) administrator was able search for the corresponding work order containing the missing part. Once found, he clicked on the work order event and was automatically provided with recorded video of the maintenance employee’s actions at the time of the event. The video showed the employee mistakenly taking two components when the work order only called for one. The component was re-acquired and put back on the shelf. The IVC video solution resolved a $10,000 problem in a few minutes.

As a result of their early success, the company has plans to roll out the IVC warehouse tracking system to their remaining 20 maintenance inventory warehouses.

To find out more about all the components used in this case study, check the application note.

The case study was written by Paul Vanslette, Chief Technology Officer at Industrial Video & Control, being responsible for planning and leading the initiative to design, develop, and implement industrial video software solutions for manufacturing, SCADA, and security applications that provide a sustained competitive advantage. IVC is the global market leader in industrial network video, driving the integration of digital video with SCADA applications. IVC products and solutions focus on industrial surveillance and monitoring solutions for security, productivity, and safety applications.

The case study was written by Paul Vanslette, Chief Technology Officer at Industrial Video & Control, being responsible for planning and leading the initiative to design, develop, and implement industrial video software solutions for manufacturing, SCADA, and security applications that provide a sustained competitive advantage. IVC is the global market leader in industrial network video, driving the integration of digital video with SCADA applications. IVC products and solutions focus on industrial surveillance and monitoring solutions for security, productivity, and safety applications.