Five steps to master digital transformation in manufacturing

It is still early innings for the Industrial Internet of Things (IIoT), and the fourth industrial revolution has barely begun, yet organizations without a digital strategy are already falling behind. This trend toward more connectivity, data, computing, and technology will only grow. Enterprises that begin their digital transformation journey, will, in fact, take advantage of the new technologies that can help them achieve their business goals.

To maximize IIoT project return on investment (ROI), enterprise information technology (IT) and operational technology (OT) professionals need to work together. IIoT solutions can virtualize control systems from multiple manufacturers and converge them under a single administrative platform. They can restrict control access to on-premise workers and transmit analytics off-site for strategic planning. But reaching the point where all of these moving pieces come together in a real-world production environment can be messy. Many OT devices come up short in key areas, such as interoperability and security, due to the prevalence of over proprietary protocols, in the legacy machine-to-machine (M2M) market out of which IIoT grew. IT and OT must work together using the appropriate protocol converters and taking the necessary security measures to both connect and protect mission-critical operations. If they can do this, it can result in a converged system that they can update and adapt far more easily than before.

With a converged IT/OT system, IT can regulate access to IIoT tools, ensuring security. The appropriate stakeholders can then monitor digital twins, running digital tests and simulations based on near real-time, real-world data to optimize the performance of all sorts of assets, reduce downtime, and perform predictive analysis for failing parts. IIoT tools can also empower the integration of other technologies, such as augmented reality (AR), collaborative and connected robotics, and product lifecycle management (PLM). A converged IT/OT system with IIoT tools feeds into PLM software for improved data management.

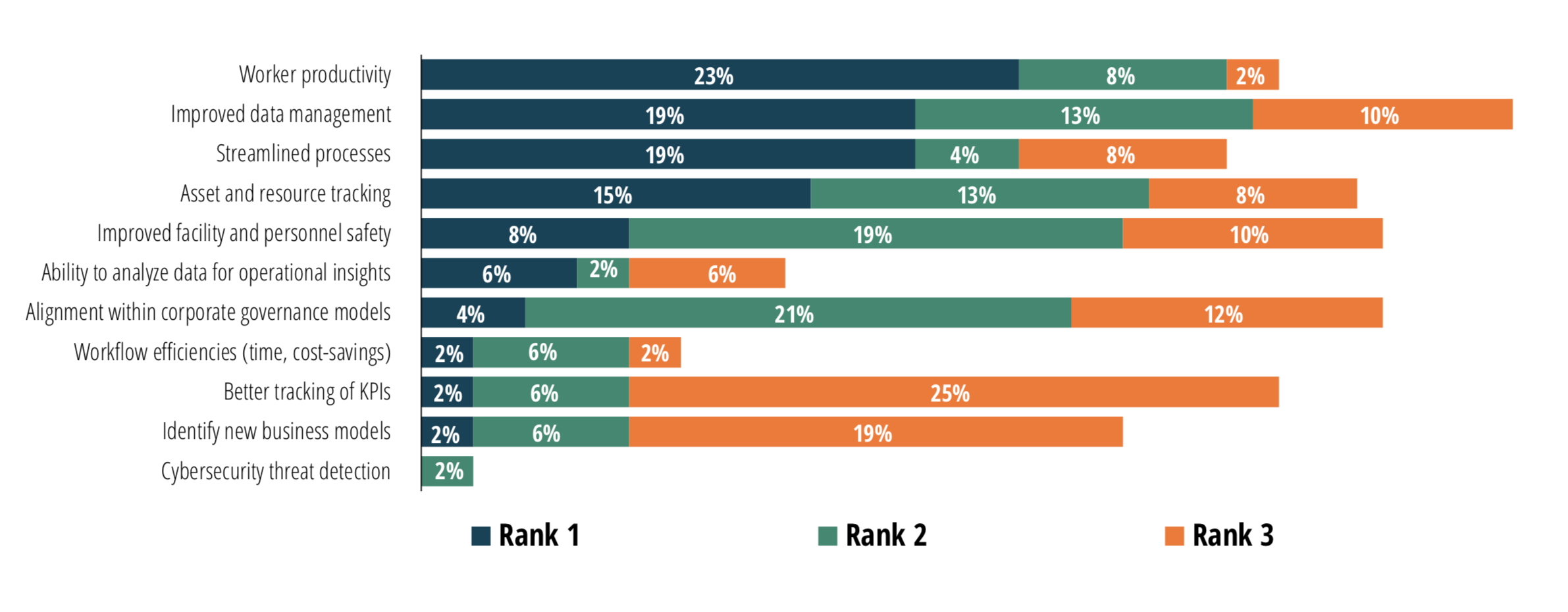

In a recent survey conducted by ABI Research, when asked to rank the most desired outcomes of applying emerging technologies to manufacturing organizations, respondents ranked “improved data management” in the top three more than any other outcome, as seen in Chart 1 below.

To achieve this level of IT/OT integration and make the digital transformation, ABI Research provides strategic guidance in the form of the following step-by-step framework, which is explained in greater detail in this whitepaper.

Are you and your organization prepared for digital transformation? Where are you on the path, trailblazing full steam ahead or lagging a bit behind? As the world’s most respected digital transformation conference, LiveWorx brings to you this whitepaper from ABIresearch: Five Steps to Master Digital Transformation.

The white paper covers:

- The challenges and solutions for digital transformation

- Four core technologies to implement into your business

- A step-by-step framework to execute.

- Managing the Risks of Digital Transformation

- Challenges of Digital Transformation in Manufacturing

No matter where you are on the journey to digital transformation, this information will empower you to achieve your business goals.