Four pillars of the industrial IoT | SPONSORED

The fourth industrial revolution is making manufacturing faster, smarter and leaner. Known as Industry 4.0, this wave sweeping across factory floors takes automation to the next level. Using the Industrial Internet of Things, manufacturers can connect the physical world with the digital and take complete control over systems as never before. Manufacturers can harness data to cut costs, improve performance and increase productivity by leveraging an open, industrial IoT as a service solution like Siemens’ MindSphere.

Although a digital transformation may seem overwhelming, the transition can be achieved in just four phases. Download the white paper to find out what are the four phases.

Although few companies (4 percent) are fully integrated now, more than 70 percent have already completed at least one IoT project or are researching and implementing a project; and nearly 90 percent of those who have completed a project are looking into additional projects.

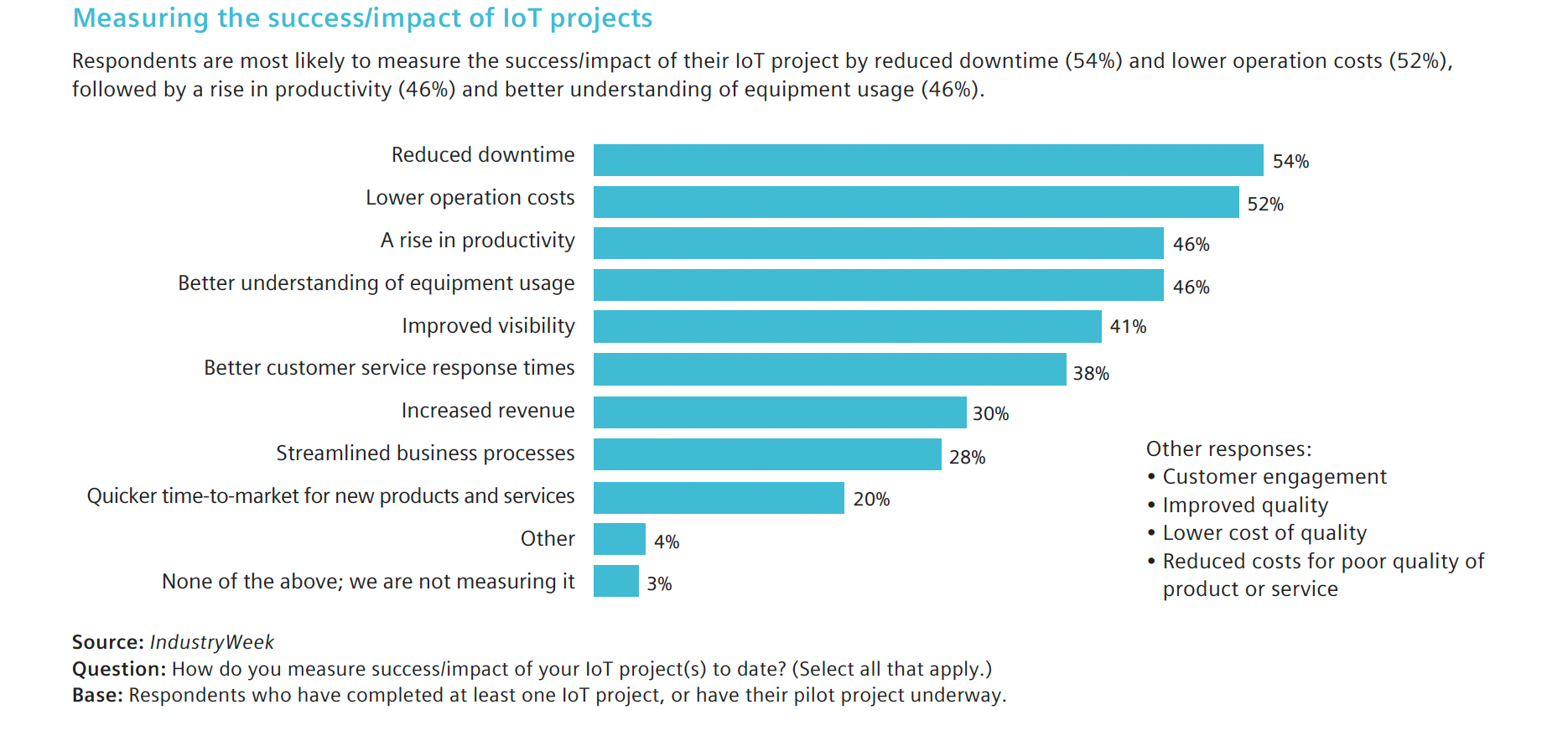

Those who have finished an IoT project report achieving reduced downtime, lower operating costs, increased productivity, and a greater understanding of equipment (see chart below) and how to optimize it.

Download the white paper to understand how to make the digital transition and take full advantage of the opportunities offered by Industry 4.0. Learn the importance of adopting IoT for manufacturing sector.

Sponsored by Siemens