In the Oil and Gas industry, the consequences of hydrocarbon leaks can be severe. Gaseous and liquid leaks of these products can result in fires, explosions, and environmental contamination. These calamities could likely cause harm to employees and the public as well as irreversible damage to company infrastructure and the environment. As the production and distribution infrastructure for these products expands worldwide, leak detection technologies and stricter regulatory framework are helping to reduce leak events and, if they do occur, identify them early enough to reduce the likelihood of a devastating event.

Hydrocarbon leak detection systems & technologies

To continuously protect well sites, production facilities, pipelines, and storage tanks from catastrophic leak events, an efficient detection scheme should be integrated into the operation’s control system. Today, there are a variety of technologies to consider. Most commercially available solutions fall into one of the following categories:

- Physical inspection (direct or remote)

- Discrete sensing (vapor, liquid, acoustic)

- Computational monitoring

Each of these approaches have their advantages and disadvantages. A comprehensive system will likely use a combination of these technologies. This article focuses on the visual leak detection technologies that are currently available.

Historically, continuous visual inspection systems were provided by thermal and/or optical cameras. In the past, disadvantages of using these products included cost, low resolution, deployment complexities, and lack of alarming.

Today, optical and thermal camera technologies continue to become more capable and less expensive, making them more viable for broad use in leak detection systems. Networking and communications technologies are also more advanced and cheaper to implement. Along with sophisticated camera management software that facilitates the integration with process control systems, these can be combined to provide a reliable leak detection system.

Visual Gas Leak Detection Technologies

Equipment that is currently available to provide a state-of-the-art continuous physical leak detection solution include:

Spectroscopic Cameras

Mid-wave or Long wave Infrared (IR) cameras equipped with optical filters coupled with analytic software allowing for imaging of the spectral absorption of specific gas wavelengths. This is probably the most sophisticated method of leak detection and can even image tricky to-see methane and ethane. These cameras are best suited for mid to long range gas cloud detection.

Thermal Cameras with Onboard Analytics

Long wave IR cameras that can measure and relay temperature differentials of a field of view are used to observe abnormal temperature signatures generally seen in high pressure leaks. Using integral analytics, the cameras can detect and image the vaporization stemming from a leak and automatically generate alarms based on the leaks behavior. Visual cameras are oftentimes used in conjunction with the thermal imager to discern between real and false alarms. Pipelines (transporting natural gas liquids) and other pressurized systems can derive the most benefits from these mid to short range installations.

Infrared Cameras

Standard Long wave and Mid-Wave IR cameras operate under a similar principal listed above but require operator input to identify a leak. Mid-wave cameras are more sensitive to the absorption wavelength of certain compounds and are often a better general-purpose method of hydrocarbon leak detection (in a variety of forms). Long wave cameras are best used in applications where potential leaks will have drastically higher or lower temperatures than the background.

Optical Video Cameras

Optical cameras operate in the visual spectrum and are unable to spot invisible gases or leaks. These types of cameras are generally used in conjunction with other leak detection equipment (cameras or discreet sensors) as complimentary safety devices. Detecting a leak and subsequently visually verifying that workers are not at risk is the primary benefit of incorporating visual cameras into a leak detection system. That being said, larger liquid leaks can be detected via a visual camera.

Pros and Cons of Hydrocarbon Leak Detection Systems

Spectroscopic Cameras (Gas Cloud Detection (GCD) Thermal Cameras):

Pros: Long Range detection and visualization of invisible, hard to detect gases like methane.

Cons: Expensive and normally requires dedicated software (on a separate computer) for analytics. Alarm integration with process control systems may also not be present. Not applicable for liquid leaks and short ranges.

Thermal Cameras with On-board Analytics (Radiometric Thermal Cameras):

Pros: Inexpensive compared to other technologies. Can be used to detect liquid leaks (due to temperature differentials). Works at most ranges depending on lens size. Has multiple use cases outside of just leak detection.

Cons: Software is required for analysis & alarming (although this can be loaded in the camera, on the edge). Configuration of software is often environment dependent and can be complicated. False alarms are more common than with dedicated detection equipment. Certain compounds are not detectable (Benzene Butane Ethane Ethylene Heptane Hexane Isoprene Methane Octane Pentane). Works on a different absorption spectrum than Mid wave cameras.

The price/performance ratio of radiometric thermal cameras is continuing to improve. Manufacturers that use this technology as the core of a leak detection system are integrating additional on-board intelligence that enable these cameras to: Detect specific types of hydrocarbon gases and liquids; Mitigate false alarms & communicate directly with SCADA systems using industry standard protocols such as MODBUS and OP.

The price/performance ratio of radiometric thermal cameras is continuing to improve. Manufacturers that use this technology as the core of a leak detection system are integrating additional on-board intelligence that enable these cameras to: Detect specific types of hydrocarbon gases and liquids; Mitigate false alarms & communicate directly with SCADA systems using industry standard protocols such as MODBUS and OP.

Mid wave IR Thermal Cameras:

Pros: Detects invisible, hard to see gases (methane, ethane, etc). Can be used at all ranges.

Cons: Expensive compared to Long wave technology. Has a limited equipment lifespan – maintenance on the cooled thermal core is required after prolonged use. May not have analytics, alarming, or integration features (and if it does, it adds even more to the cost).

Long wave Thermal Cameras (nonradiometric):

Pros: Increasingly becoming very affordable. Can work with liquid leaks (via temperature differentials).

Cons: Alarming not possible (requires operator analysis and input). Cannot detect certain compounds. False alarms can be very common.

Optical Video Cameras:

Pros: Most cost-effective option. Useful for more than just leak detection (process monitoring, operator safety, etc.). A wide range of certified (ex-proof, UL & IECEx) available.

Cons: Cannot detect leaks unless they are clearly visible (so fugitive gases will not be detected at all). Last resort for leak detection as the cameras are really designed for security, safety, and process monitoring.

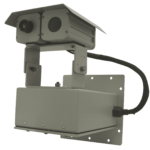

Ideal leak detection solution providers are those with experience with a variety of sensor technologies and the ability to provide a product that easily integrates with the facility’s control system. For example, the camera pictured above includes thermal and optical camera sensors. The thermal sensor provides the leak detection alarms, while the optical sensor gives the operator a chance to visually verify the situation before taking action.

Ideal leak detection solution providers are those with experience with a variety of sensor technologies and the ability to provide a product that easily integrates with the facility’s control system. For example, the camera pictured above includes thermal and optical camera sensors. The thermal sensor provides the leak detection alarms, while the optical sensor gives the operator a chance to visually verify the situation before taking action.

What to Consider when Choosing Hydrocarbon Leak Detection Technology

As mentioned earlier, a comprehensive hydrocarbon leak detection system will likely be comprised of multiple leak detection technologies. What your solution looks like will depend on the following factors:

- Product type – Can the solution detect the hydrocarbon gas or liquid under surveillance?

- Leak size – What is the minimum leak size that the system is capable of detecting or needs to detect?

- Response time – How long after a leak is detected should the system alarm?

- Leak location – How accurately can the system locate the source of the leak?

- Release volume estimation – Does the system need to determine the volume of hydrocarbon product released?

- False alarm rate – What is the typical false alarm rate for the technologies implemented? Does the equipment in use include false alarm mitigation technology?

- Does the system automate necessary actions? – Are actions necessary to verify the leak and mitigate leak consequences automated? Is notification of stakeholders automated? Is the system easily integrated with the facility’s SCADA/DCS system?

- Cost – What will be implementation and operating costs of the system?

- Reliability – What is the MTBF of the major components of the system?

- Availability – Will the system work 24/7? How is affected by changing lighting and weather conditions?

- Ease of implementation – How easy is it to install and configure the system?

- Ease of use – Does the system present leak alarms to operators and process control system in a timely and clear manner?

- Ease of maintenance – How easy is it to repair or calibrate the major components of the system?

Summary

Hydrocarbon leak detection is both critical and complex. There is no one-size fits all solution that is commercially available. To insure an implementation that exactly meets your needs, it is most crucial to pick a solution provider that provides a platform in which all necessary technologies may be integrated. This solution should also have the capability to integrate with your facility’s control system to provide the automation necessary to keep the consequences of a leak event to a minimum. Today’s state-of-the-art visual leak detection technologies have some limitations, as mentioned above, but can be easily networked to provide a comprehensive leak detection system to satisfy the requirements for most environments. On-board camera analytics and alarming facilitate integration of a camera-based leak detection system with discreet leak detection devices and an operation’s process control system. When used with full-featured camera management software, these capabilities provide for fast responses to leak events and an easy means to automate notifications and system maintenance.

For more information, visit www.ivcco.com, send an email at info@ivcco.com or call at 617-467-3059.

This article was written by Michael Hrinishin is a technical sales manager at Industrial Video Control (IVC). IVC is a manufacturer of industrial video systems that are designed for a wide variety of safety, security, and process monitoring applications. Mike focuses on customer project management and is primarily responsible for evaluating customer video application requirements and recommending appropriate technical solutions.