As we move into 2021 and out of a crazy year that brought the challenges of a pandemic and economic disruption worldwide, many of us are no doubt ready for a new year. With sights on how technology will transform the industrial landscape the following are some insights on how innovations in 5G, Augmented Reality, 3D, and Machine Learning will evolve in the new year.

Use Cases for Industrial 5G With Video Streaming at the Forefront Begin to Take Hold

5G has been hyped in Industry 4.0 for some time with vague benefits that include things like an ‘improvement in supply chain efficiency’ without a clear path as to how that will happen. How will 2021 bring about applications that can really make use of the enormous bandwidth 5G brings?

Remote collaboration on maintenance and installation can really benefit from 3D models, or what is now being referred to as digital twins, and live video communication. As the users are typically moving around, wired connections are not really an option. Here 5G should be able to deliver an outstanding user experience with remote operators able to see what on site staff see, share data sheets and maintenance records as needed and use 3D digital twins to visualize how equipment operates.

Today 3D models are run locally on computer devices — analogous to how we used to download movies for viewing. 5G enables the ‘streaming’ of such information, similar to how we watch movies today. In 2021 we can expect to see the first full 3D video streaming for industrial purposes.

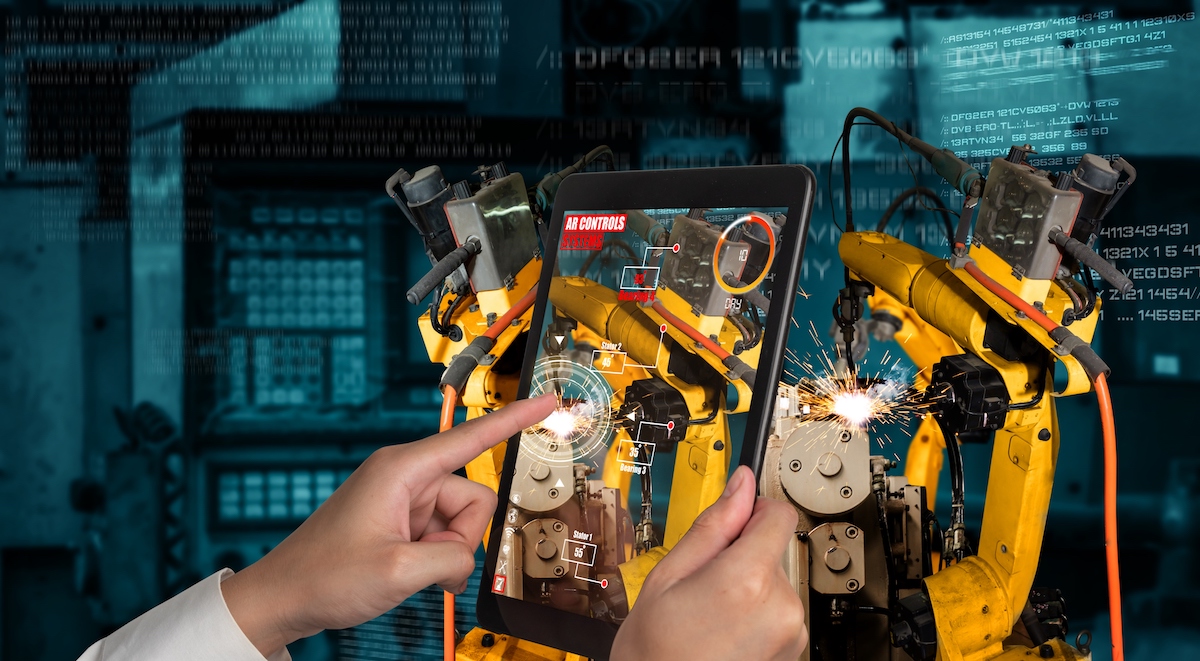

Augmented Reality For Industry 4.0 Will Come of Age

VR has found a niche in industrial applications, mostly related to training. AR has far wider use cases and 2021 will see this technology go mainstream. Head mounted devices that combine a display, camera and microphone will get much more sophisticated. Users will collaborate and view digital twins, live video, data sheets, and maintenance records using voice controls while keeping their hands free to perform needed tasks.

Beyond manufacturing industrial use cases, other industries, including construction will begin to leverage this technology. Contractors will now have the ability to tour job sites with architects and customers to walk through project evolution, explore questions remotely, quickly assess the need for change orders, and more.

3D Modeling Becomes the Norm

From 3D CAD and 3D scans to 3D digital twins, the industrial world will increasingly start to model its environments in 3D and move away from traditional 2D dashboards. The technology is available, affordable to create, much more intuitive, and has a wide range of applications. The abstract, hard to use nature of IoT interfaces has been one of the major reasons for holding back this technology. We’re used to great UI and how that innovation upended the mobile phone market 15 years ago. Great UI combined with 3D photorealistic technology is coming to the industrial world and will be a big driver in 2021.

Self Training Machine Learning is the New Normal

As anyone who has used data to train a machine learning algorithm can testify, there is a large amount of pre-processing required to normalize and tag data before it can be used to train. This has made machine learning hard to implement except in certain cases (e.g., written translation, machine understanding of voice) but 2021 will see the introduction of unsupervised learning for AI. In this application, data from a monitored device is sent to the algorithm with no human intervention. ML detects patterns of normal usage very quickly and then monitors for unusual patterns that exceed a preset threshold. For example an electric motor might be generating heat, vibration and electrical current consumption readings. In normal operation these readings generate a number of patterns but when the motor starts to fail new patterns are generated with a number of standard deviations outside the norm. This can be used to flag maintenance on machinery when required. Differences in motor type or environment make no difference to the ML algorithm’s effectiveness, it trains on each motor’s ‘normal’ operation and detects variations from that norm.

More Manufacturing Trends 2022

About the Author

This article was written by John Burton, the CEO and co-founder of UrsaLeo. Before founding UrsaLeo, John spent 30 years in the semiconductor industry working with industrial customers across Europe, North America and Japan. Seeing the vast quantities of data being gathered in IIoT environments he got together with Angie Sticher (ex-Apple) to find ways to better visualize and use that data. Hence UrsaLeo.

This article was written by John Burton, the CEO and co-founder of UrsaLeo. Before founding UrsaLeo, John spent 30 years in the semiconductor industry working with industrial customers across Europe, North America and Japan. Seeing the vast quantities of data being gathered in IIoT environments he got together with Angie Sticher (ex-Apple) to find ways to better visualize and use that data. Hence UrsaLeo.