Key Questions You Should Ask Your Industrial Video Provider

Frequently, video solutions intended for industrial use are purchased by the organization’s security department. In most organizations, operations and security are different departments. This often provides budget, control, and integration challenges within the organization. Treating the video system as part of the SCADA system rather than the security system helps to clearly delineate video’s use, purpose, form factor, and control. Video equipment intended for industrial use should be treated just like any other piece of equipment in the plant. It is time to consider video as a critical part of every plant’s operation and an important tool to improve:

- Operational efficiency

- Worker safety

- Product quality

- Loss prevention

What to Consider

Not all video solution vendors are the same. Here are some key questions to ask your vendor to make certain you get the right solution.

- Cameras are to be deployed in harsh or hazardous areas. Can you provide industrial grade cameras that are certified for use in Class 1 and Class II areas? Do you offer options such as wipers, air knifes, or cooled enclosures?

- Do your cameras include state-of-the-art HD or “temperature” monitoring radiometric thermal imagers?

- Does your system support SCADA integration technologies such as OPC or MODBUS?

- Does your video management software (VMS) support the ONVIF standard thus allowing other vendors’ cameras to be added to the system? Or am I locked into your cameras?

- Does your VMS provide synchronized playback of video based on clicking on an SCADA alarm or historical trend?

- Can I use your software to record and playback any HMI console monitor?

- For remote sites, do you have recording at the edge, remote site-wide bandwidth management, store-and forward clip upload technology, and a management system to monitor and manage the system centrally?

Who’s Integrating Industrial Video with SCADA?

21st Century Process Monitoring

Thanks to advances in networking, video, and processing technologies, video systems can now be an integral part of any critical manufacturing process. Examples of where these types of systems are now in use include:

- Food and beverage producers use video integrated with their SCADA systems to maintain product quality and ensure adherence to government regulations.

- Petrochemical producers deploy cameras certified to operate safely where explosive gases exist. Video is tightly integrated with production facilities’ SCADA system.

- Automotive manufacturers use video technology to quickly identify quality issues to maintain production efficiency.

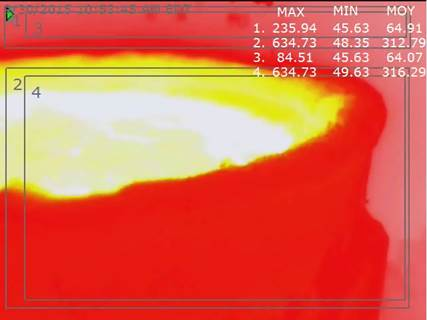

- Steel manufacturers use cameras to monitor the external temperature of molten metal ladles to warn for breakouts.

More about A Cloud Based Alternative to Traditional SCADA

This article was written by Paul Vanslette, Chief Technology Officer at Industrial Video & Control. Paul is responsible for planning and leading the initiative to design, develop, and implement industrial video software solutions for manufacturing, SCADA, and security applications that provide a sustained competitive advantage. IVC delivers a broad range of quality IP-based video systems to industrial, commercial and military applications. Their standards-based software, which delivers quality video to PCs and other client devices over a network, is designed to be scalable and easily integrate with third party software.

This article was written by Paul Vanslette, Chief Technology Officer at Industrial Video & Control. Paul is responsible for planning and leading the initiative to design, develop, and implement industrial video software solutions for manufacturing, SCADA, and security applications that provide a sustained competitive advantage. IVC delivers a broad range of quality IP-based video systems to industrial, commercial and military applications. Their standards-based software, which delivers quality video to PCs and other client devices over a network, is designed to be scalable and easily integrate with third party software.