The missing piece in the IIoT

Buzz words such as the industrial Internet of Things (IIoT), Industry 4.0 and Digital Twin have started to weave their way into executive key notes and sales peoples’ pitches. It is easy for product offerings to get lost in the cloud of buzzwords and become disconnected from the basic operating principles of the customers in which these products were originally developed.

Back to basics

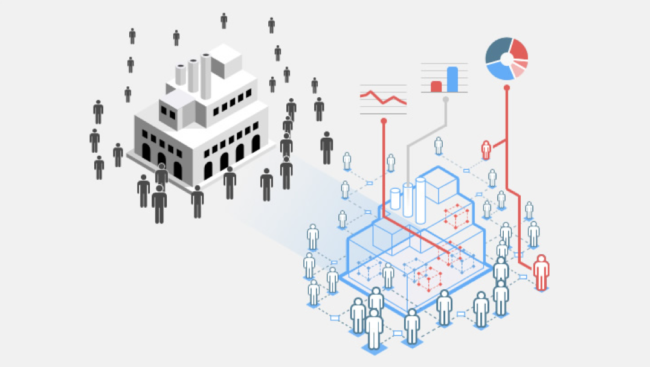

Most Industrial IoT customers produce a product such as oil, chemicals, motors, etc. This requires two primary assets; Physical Assets – machines, plants, mobile rigs, etc; and Human Assets – operators, maintenance, engineers, and managers. These two assets dance together in a process to produce a desired outcome e.g. crude, cars, widget xyz.

Digital Twin defined

The term Digital twin is rapidly making its way into the everyday technology dictionary. Defined as a “digital copy of physical and human assets that can be used to analyze and simulate real world conditions, respond to changes, improve operations and add value.” Gartner even has listed Digital twin as a top 10 digital trend of 2017.

The Missing Piece

Most technology players in the space are developing and marketing to the physical side of the asset equation. With the typical pitch being something along the lines of “With connected devices we can connect your assets and, with all your data we can predict downtime, asset failure, benefit xyz.” This over emphasis on the physical asset side neglects the other half, which are the humans. Physical asset data alone is not a complete picture of what operations are today. Physical asset data plus Human data is now a must.

Further reading: 3D Digital Twin used for decarbonization and energy management optimization and The Benefits of Using the Digital Twin in Manufacturing

Humans (unfortunately) remain an operational reality and are responsible for operating, maintaining and ultimately optimizing the physical asset. Having data on what people are doing, how, when, where and if they even did it to begin with helps to identify risks and opportunities. This improves and completes the Digital Twin value proposition which simply is “Show us a lot of data and we’ll show you how to improve”.

Our market prediction

The Industry 4.0 / Industrial IoT market battle is hot with all the major players and startups arming themselves to start to collide. Our prediction is that the fastest players to combine both the physical AND the human side of the asset data equation are going to provide the most value and ultimately win. Leaving all the others wishing they executed faster rather than nodding their head in agreement and still leaning one comfortable way. The way they have always leaned. The way that feels safe, but, as history tells, is the most dangerous.

This article was written by James McDonough, a passionate tech CEO. James has had the pleasure of being invited to deliver speaking engagements at a number of industry forums and top universities all over the world on a range of topics including entrepreneurship, innovation, industrial internet of things (IIoT), and was an honorable mention in Australia’s 30under30. James has earned a MBA – Master of Business Administration, Honours in Business Management, and a Black Belt in LEAN Six Sigma.

This article was written by James McDonough, a passionate tech CEO. James has had the pleasure of being invited to deliver speaking engagements at a number of industry forums and top universities all over the world on a range of topics including entrepreneurship, innovation, industrial internet of things (IIoT), and was an honorable mention in Australia’s 30under30. James has earned a MBA – Master of Business Administration, Honours in Business Management, and a Black Belt in LEAN Six Sigma.