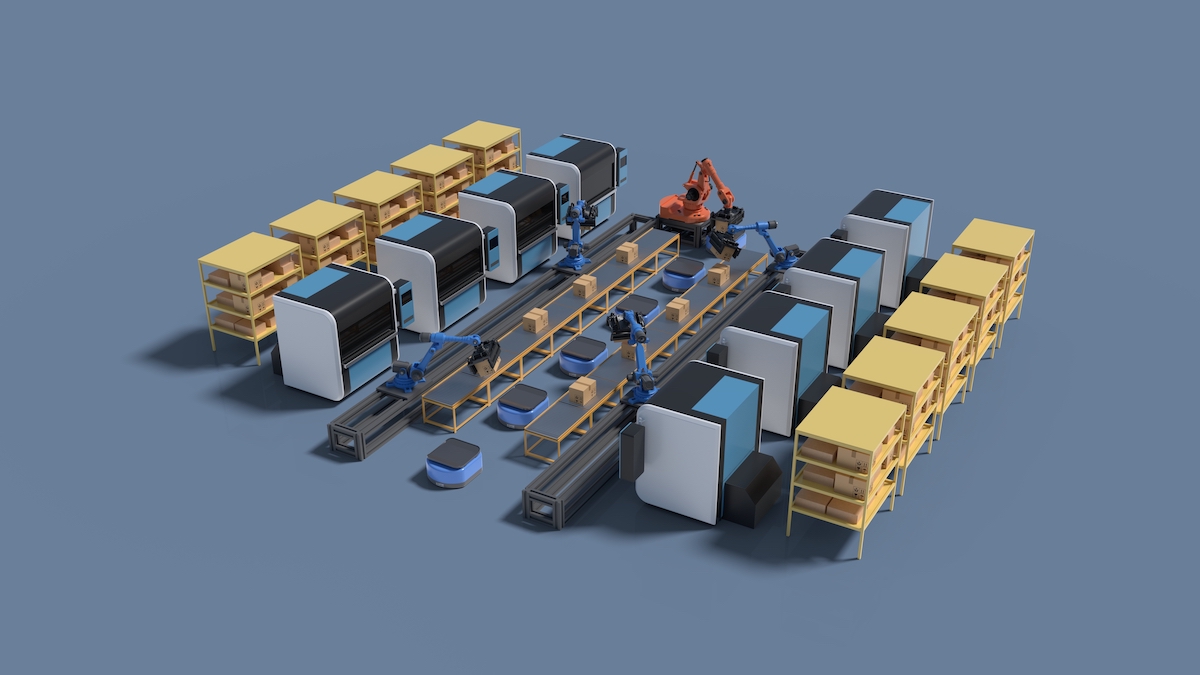

Returnable Asset Tracking – Operating Principles

Before moving forward with an investigation into tracking returnable assets, it is important to understand the available technologies, their capabilities, and how they relate to tracking functions in a production facility.

Asset Tracking Technologies

There are different tracking technologies typically used in a production facility. Depending on the amount of data transmitted and the complexity of implementation each have corresponding price points.

Low cost – low complexity

Manual, semi-, or automatic code scanning

The manual manipulation of hand scanners requires time for processing and allows for error in recording.

The cost of implementation is low, but systems require consistent investment of time devoted to ensuring accuracy.

The cost to serialize assets for tracking is low, but the data can be damaged and capacity/flexibility for data storage is limited.

Low cost – medium complexity

Automatic tracking with RFID technologies

A completely automated RFID tracking system is reliable and allows for tracking of units in motion (eliminating small stops).

The cost of implementation is medium, but this system allows for expansion and flexibility for additional capabilities.

The cost to serialize an asset is low, there are no batteries to maintain, there is large storage capacity with data manipulation.

High cost – high complexity

Real time tracking with RTLS systems

Completely automated RTLS systems are reliable, and allow for real time localization of an asset. They are the best fit for intralogistics.

High cost of implementation, and very complex. Useable location(s) requires plant-wide transponder grid.

The cost to serialize an asset is high, requiring active battery powered tags to relay location data through a grid of fixed gateways and wireless trilateralization.

Find out more about why is the UHF the chosen technology for asset tracking; what does this mean?; how to enable tracking with intelligence, what is an asset tracking portal; example of modular asset tracking portal by ifm; ifm controls architecture; antenna types; encoding and decoding GRAI and hot to get started.

More articles on asset tracking here:

About the author

TJ Berlin is ifm’s North American Product Manager for Identification Systems, including industrial multi-code readers and LF/HF/UHF RFID tracking solutions for production and intralogistics/logistics processes. With seven years experience as a technical sales engineer, TJ gained extensive exposure to plant operations, improving equipment efficiency, and logistics and supply chain optimization within various industrial markets. Currently focusing on new camera technologies and possessing a comprehensive understanding of RFID in tracking systems for high speed applications, TJ maintains, “I hope to continue to develop and offer solutions that maximize efficiencies in tracking and tracing in the age of Industry 4.0.”