[Summary] Successful Software Safety Certification

When it comes to developing safety-critical systems like industrial equipment, automotive systems and medical devices, avoiding certification is no longer an option, nor is it easy. Just a decade ago 75% of companies embarking on certifying software against a safety standard, failed. As each certification project requires an immense investment of resources and engineering time, failure is expensive.

Overcoming the odds against successful safety certification requires business leaders to drive a company-wide safety culture, and for development teams to adopt new processes as new safety standards become goal-based. Chris Hobbs, author and functional safety expert, shares practical advice for R&D leaders he’s gained from years of first-hand experience working on safety projects.

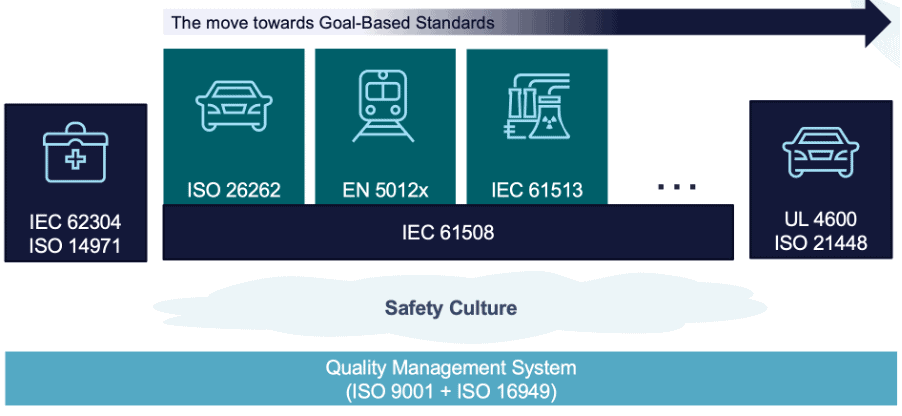

Following his advice, you can learn how to set your teams up for success when pursuing safety-certification standards such as ISO 26262, UL 4600 and IEC 61508, how to develop “sufficiently-dependable” software that meets availability and reliability needs with minimum development effort and why functional safety is so important to staying competitive.

Software Safety Certification Isn’t Easy

In 2010, research by Martin Lloyd and Paul Reeve showed that for IEC 61508 and IEC 61511 assessments, only 25% of the 12 software-based certifications had succeeded. In 75% of these cases, companies spent significant time and money, but didn’t receive a certificate. By 2016, the success rate was much higher… because fewer companies were starting the process, not because they were getting better at it.

Chris Hobbs explains that traditional software safety certification projects are changing for these reasons, among others:

- The complexity of the systems is making prescriptive metrics inappropriate

- Goal-based developments can inspire the best developers and intimidate others

- The purpose of testing and verification is changing

- Upper management’s role in fostering a Safety Culture is changing

The Evolution of Safety Standards

Hobbs goes on to explain the movement toward goal-based standards, with the idea being that the focus is producing a safe product, not the process in getting there. So prescriptive standards where steps 1, 2 and 3 must be followed are going away, now the goal is to demonstrate that the product is adequately safe.

This movement from prescriptive standards to goal-based standards also requires a shift in leadership. Instead of a prescriptive approach, e.g. “Show me how many points on the checklist have been completed”, management must now take a goal-based approach, e.g. “How many of the identified hazards and risks have been mitigated? Convince me the system is adequately safe.”

Watch the on-demand virtual conference with Chris Hobbs, “De-Risking Sofware Safety Certification: How to Lead Your Organization to Certification Success” to learn more, including the 5 steps to creating the “safety case,” creating an organizational culture of safety and more.