Think 2018: must-see video recordings of the sessions and key takeaways

“It is a moment that happens, probably, every 25 years, it’s an exponential moment when both, business and technology architectures change at the same time. This moment has a potential to change everything, and If you are able to learn exponentially, you become the disruptor instead of being disrupted.” This is how the IBM Chairman, President and CEO, Ginni Rometty, began her speech at Think 2018 event, that took place last week in Las Vegas. It was inspirational, it was insightful, and it made those 30 000+ attendees think how they use the data today and how AI can help to take better business decisions in the future. We also found out that only 20% of the data is searchable today, which means that there is a tremendous potential to explore the other 80% and to learn exponentially.

Ginni Rometty also talked about three inflection points of Think 2018:

- It’s an inflection point of IBM clients’ business. All these companies, according to IBM’s CEO, will leverage digital platforms, will embed learning in every process they run and will empower people with all forms of digital intelligence. “This will be an era of man plus machine, not an era of man versus machine.”

- The second inflection point is about society

- The third one it’s an inflection point of IBM.

See the full speech here.

During the event, IBM announced Watson Assistant (one of the crowd favorites on the Think 2018 showroom floor was Harman’s Maserati GranCabrio, which features the newly-announced Watson Assistant), IBM Cloud Private for Data that will be available this year. IBM also announced a new, lower-cost plan for firms looking to develop blockchain applications.

We also found out about IBM Garage, a great concept for every company that plans to step into Digital Transformation process. For all announcements at Think 2018, check this link.

It was a massive event with 2768 sessions, 21 industries, 26 topics, 36 keynotes, all of these in four days. For those who did not have a chance to attend this year’s event, you can watch on demand all the recorded sessions here.

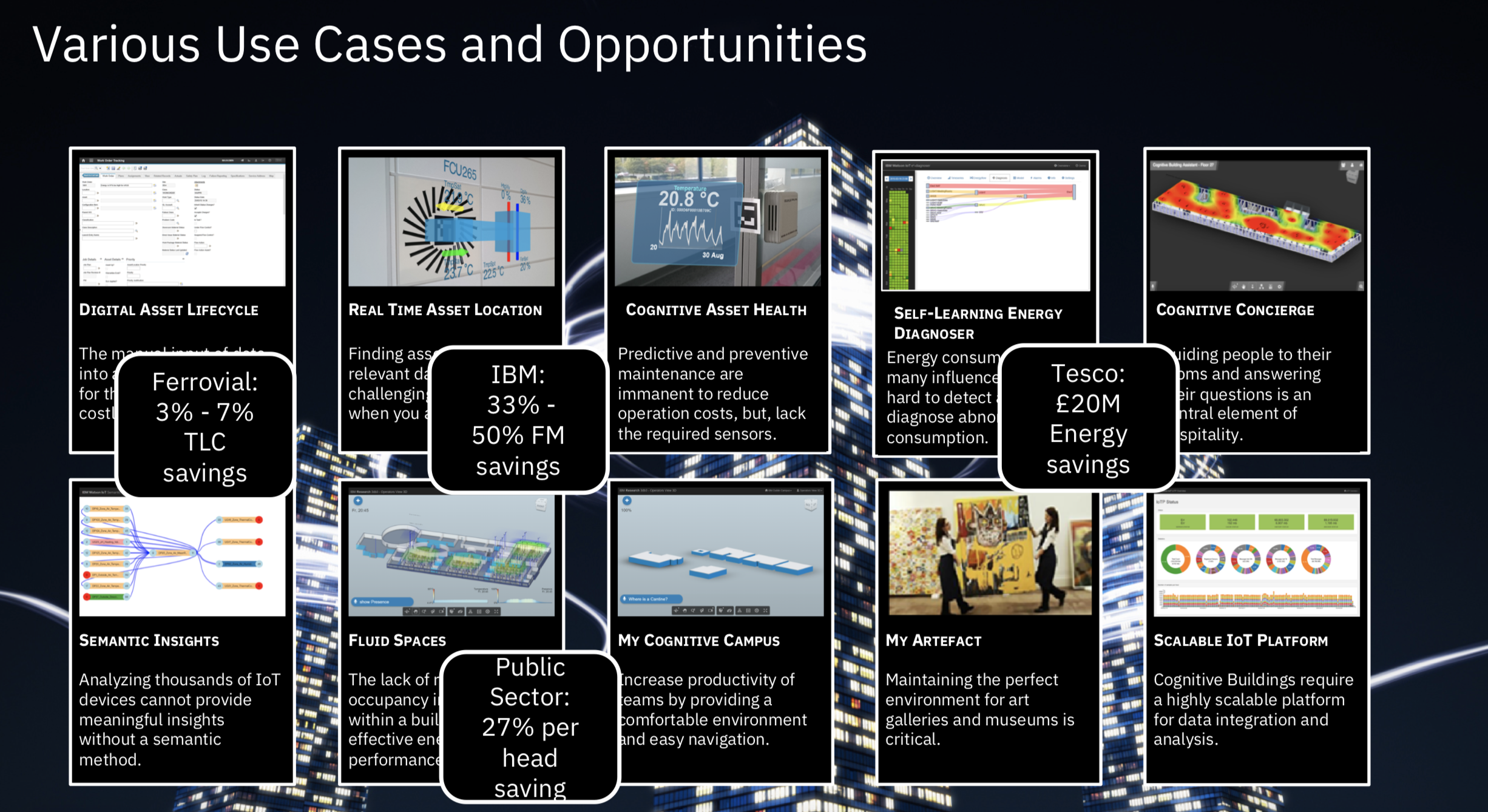

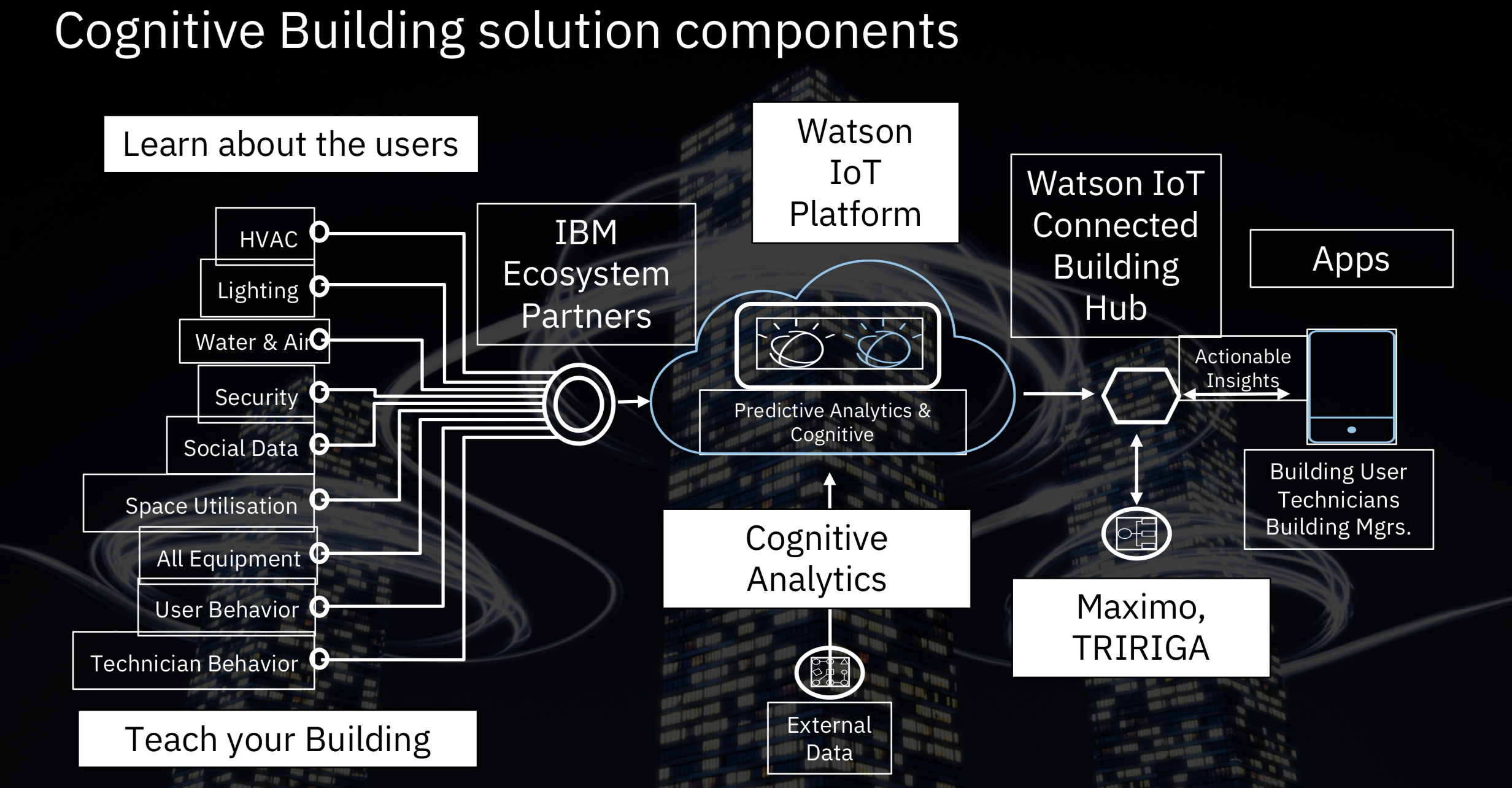

Smart buildings/smart cities

As a digital media outlet focused 100% on Industrial IoT, being a part of the Futurist Think Social VIP program, we attended a few sessions focused Industrial IoT and smart buildings. My partner, Lucian Fogoros, was panelist in the “AI-Powered Buildings: Activating a New Level of Productivity” session . Here is a live recording.

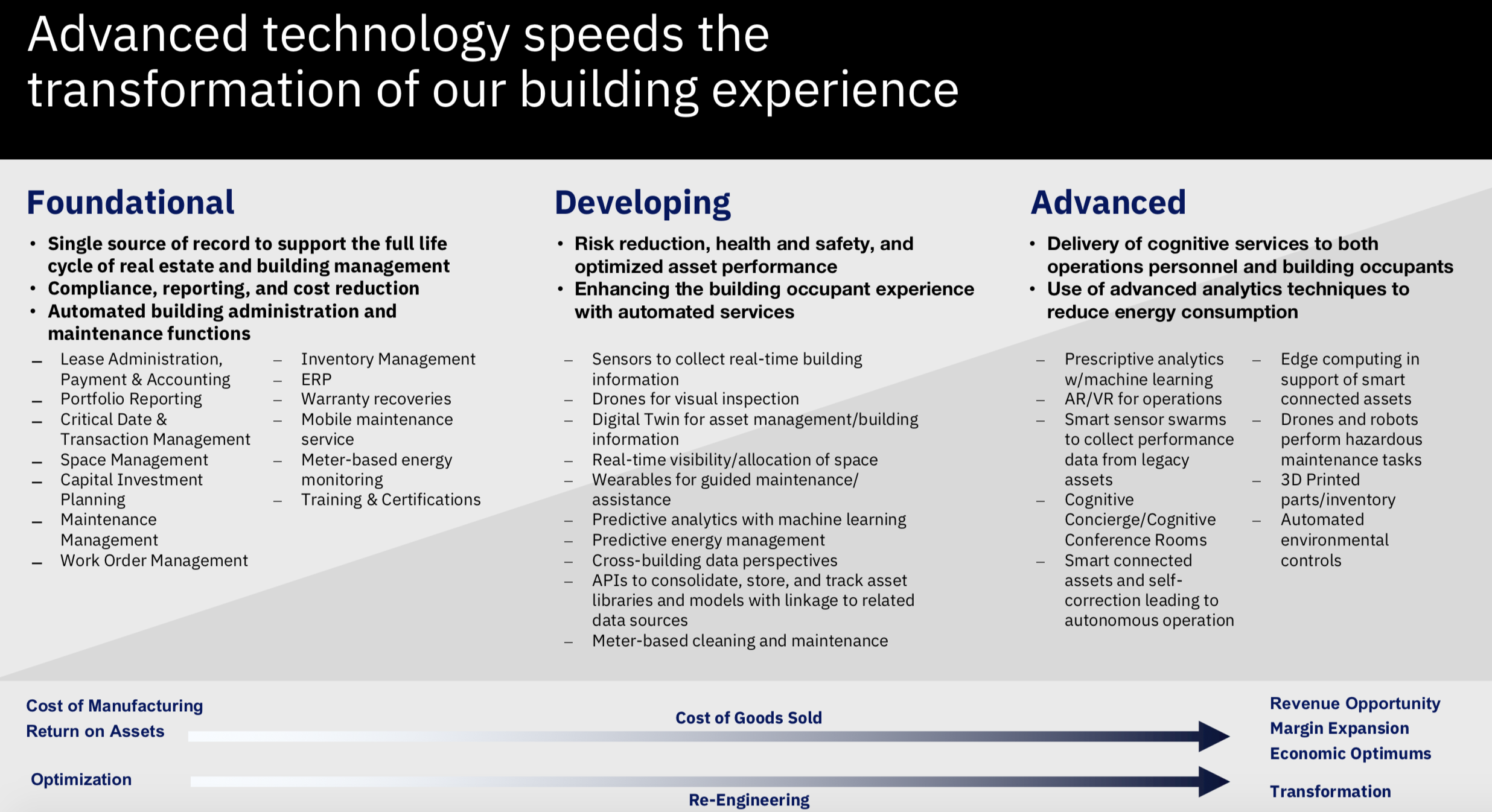

We also attended several other two sessions focused on smart buildings: “Buildings 2050: The Cognitive Building and Digital Twins” and “Building a blueprint to smart buildings / How to plan and prepare for the future”.

Key takeaways

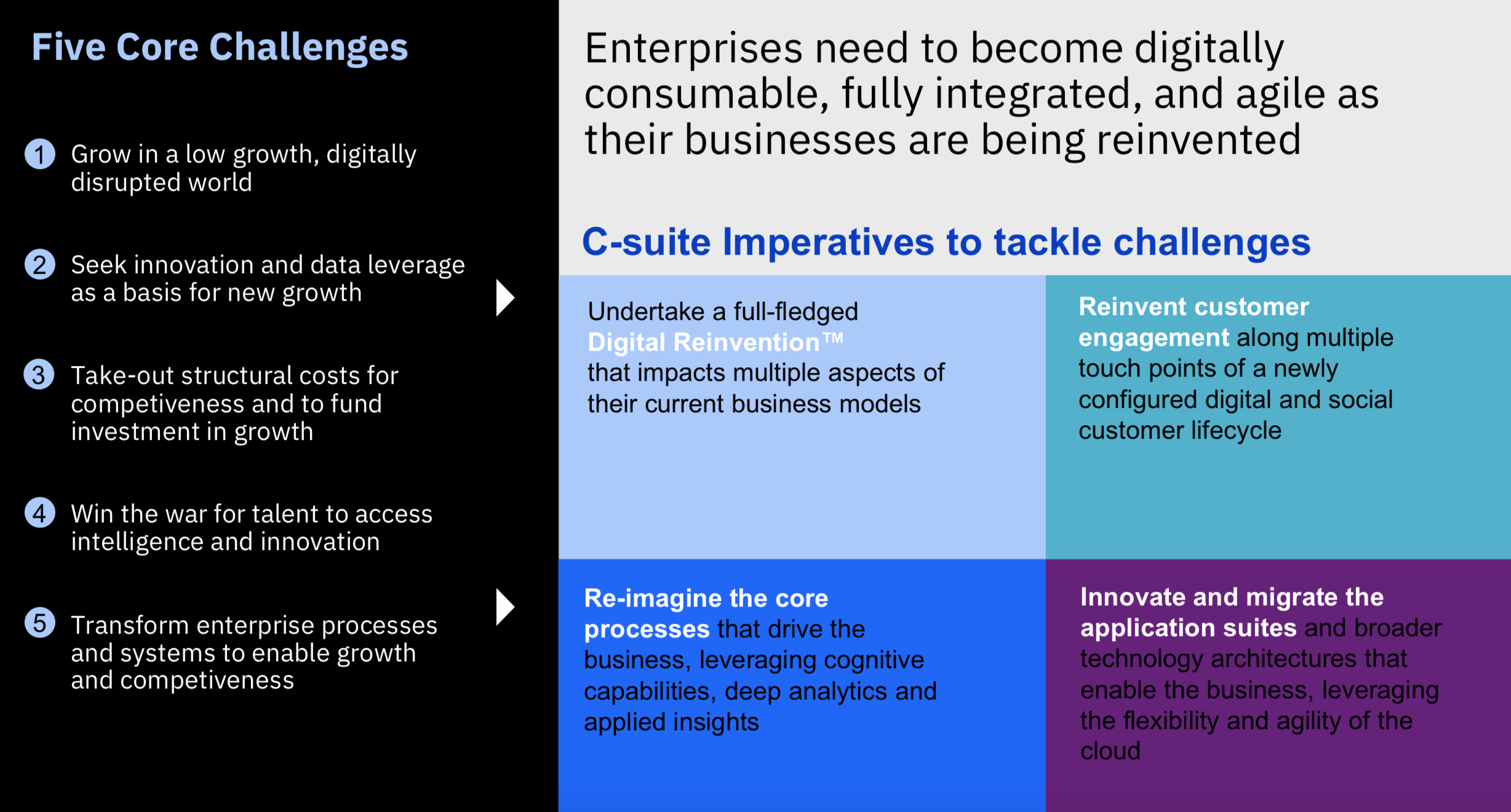

- Enterprises need to become digitally consumable, fully integrated, and agile as their businesses are being reinvented.

- Transformation focus is key to achieving exponential improvements in building performance

- There is a huge digital transformation opportunity in the construction industry, as this is the least digitized one in the US and 2nd least digitized in Europe, according to a study published by McKinsey Global Institute in 2017.

- Only cognitive unlocks the potential of all data. By the year 2020, about 7 MB of new information will be created every second, for every human being on the planet

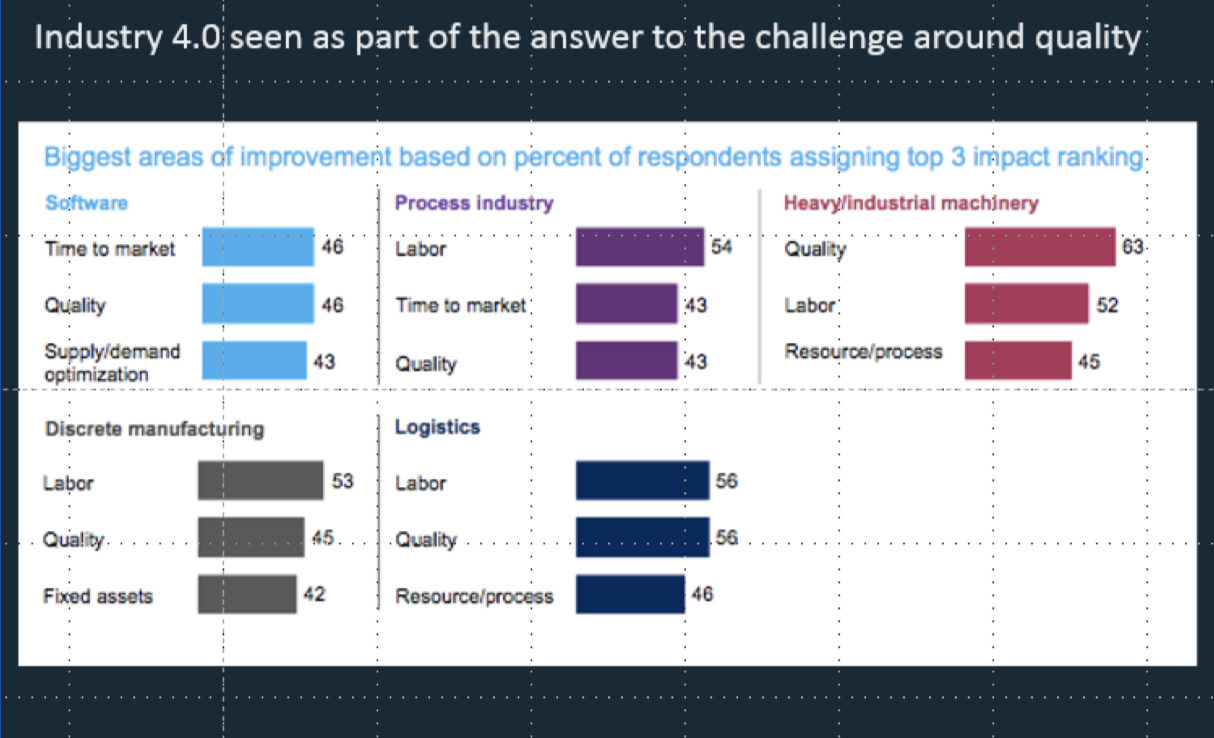

Smart Manufacturing

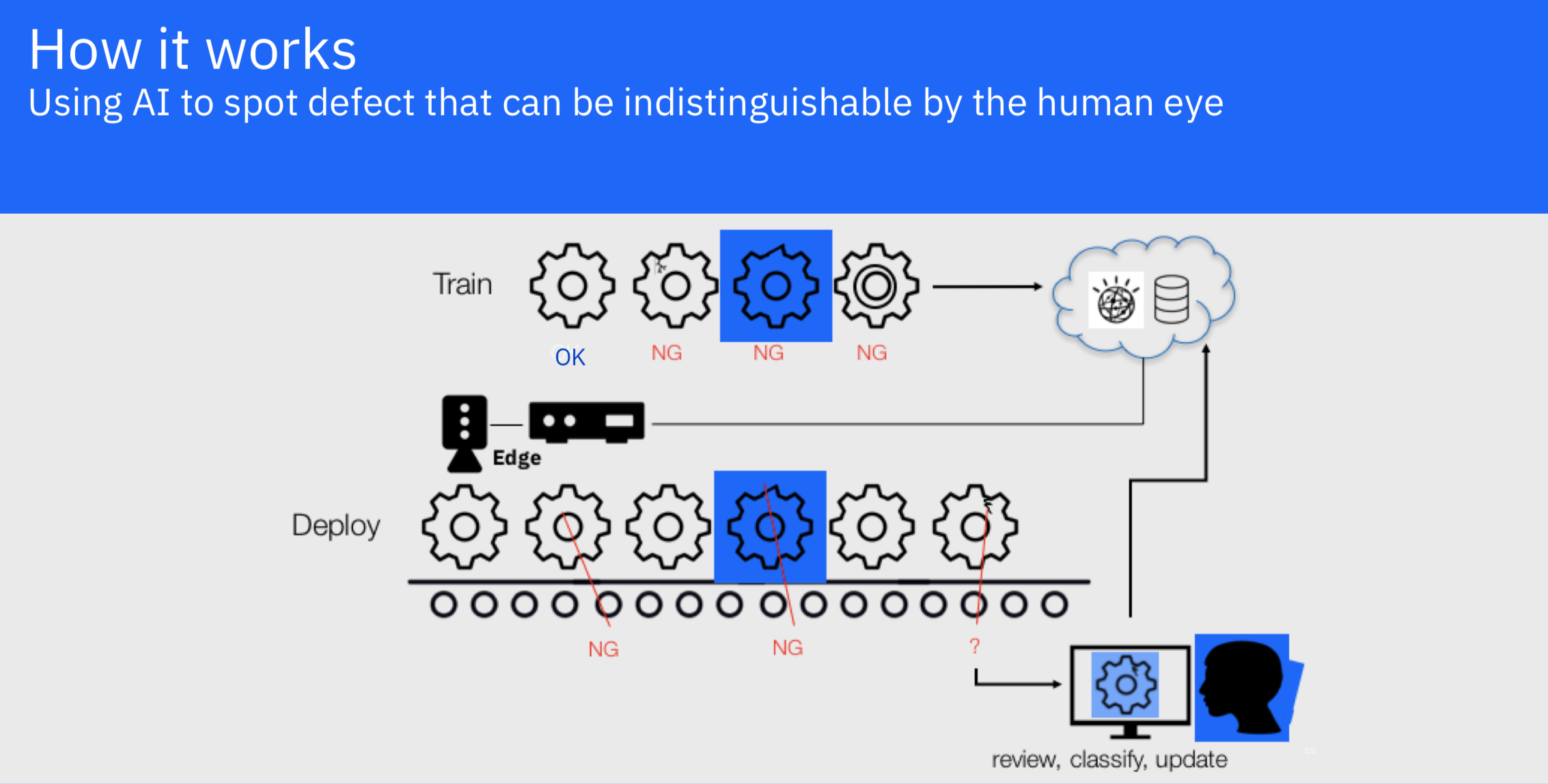

The cost of quality in manufacturing is rising, and traditional methods cannot keep up. Manual inspection of products can be slow, costly, ineffective and dangerous. With visual insights, IBM is helps manufacturers detect defects instantly applying AI.

McKinsey believes manufacturers can see 10-20% improvement in cost of quality through Industrial IoT.

Below are the most significant areas of improvement based on the percent of respondents assigning top 3 impact ranking:

Key takeaways:

- Visual Insights can be applied across multiple industries and at the edge

- Drives identification and management of defects using the power of Convolutional Neural Networks, providing visualization of real-time KPIs of the inspection processes (avg defect rate, frequency, etc.).

- Customers can achieve productivity increase, increase in defect detection rates, early warning of product quality issue patterns.

A part of this session (Industrial AI), presented by NVidia, can be accessed here.

A must-see video is our live tweet about collaborative robots that are using IBM visual insights to detect defects in production. Phil Derbyshire, Industrial IoT architect for IBM in the Industry Lab Munich, explains for IIoT-World how the robot is trained to recognize defects and how easy and fast is this process of learning.

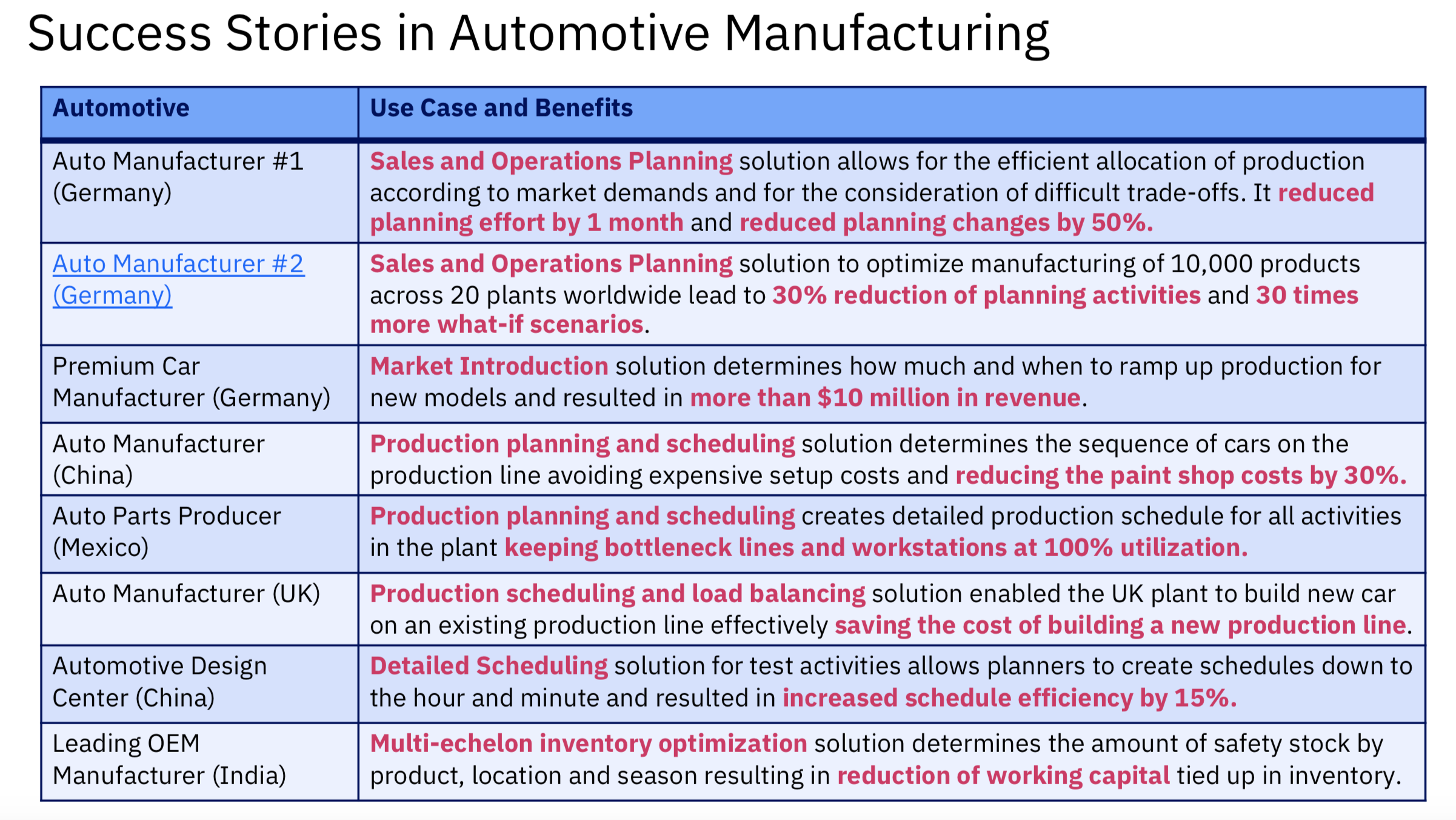

Another session we attended was “Manufacturing Industry Best Practices for Better, Faster, Smarter Decisions with IBM Analytics.” Bellow find a few case studies in Automotive Manufacturing that are leveraging Machine learning and decision optimization.

To see more examples of leveraging these techniques in product design and engineering, in inventory optimization, product planning, and scheduling or operations planning, see our live tweet from the event.

Other two must-see sessions are “Putting Smart to Work in Operations” and “How the IoT is Transforming Operations.”

Manufacturers are under pressure: The need to do more with less often means finding ways to save money and expand margins. Smart companies are turning to AI technology and IIoT principles to power their manufacturing transformations. They are using data from their operations plus advanced AI technologies to drive outcomes related to cost drivers like downtime, quality, and resource optimization. See our live tweet from the first session.

Here are the other three tweets from the second session:

Live Tweet 2 – Golden State Foods

Live Tweet 3 – Sandvik Mining and Rock Technology

Operating the energy systems of the future

One of the presentations was focused on operating the energy systems of the future. It was about today’s energy challenges and transformation in this industry, ABB’s digital positioning, what is the Internet of Energy and how ABB works IBM combining operational data with artificial intelligence to reduce costs and risks associated with the forecasting of renewable power generation.

Another presentation focused on the Energy Revolution and the Fourth Industrial Revolution can be accessed here. The IoT and AI: This Changes Every-thing keynote was about how Harman or Jaguar Land Rover are using AI and IIoT in their operations.

Also, we attended “Connecting Legacy Devices to Watson IoT” session where Opto22 presented a case study and a demo showing how Industrial Internet of Things (IIoT) can be leveraged to respond to dynamic energy pricing. For more resources about Automation 101 series and Opto22’s Node-RED video series, check this link.

If you’re interested to find out what IBM considers as five breakthrough technologies that will change the world, this is the video to watch.

The images in this posts were selected from the presentations made during IBM Think 2018.