Three factors why Industrial IoT adoption is slow

The age of Industrial IoT (IIoT) is here. With IIoT the real-time data-net can sweep more broadly than ever before. However, companies in industries everywhere continue to use human beings to monitor their critical assets.

Oil and gas companies ask field technicians to drive tens to hundreds of miles to take inventory of water used for fracking. Environmental consulting firms still find themselves traveling to remote and dangerous parts of the world to assess fire risk. Agriculture and chemical distribution companies still use a hammer to ping their tanks to know tank levels and volumes. Water resources management, transportation, and tank monitoring are just a few of examples of inefficient monitoring that still goes on today.

All of these human heavy tasks can be performed remotely by machines. But why is IIoT adoption slow? Three factors come to mind. To earn the business of these organizations and industries, you must understand the following:

- Technology of IIoT

- Physical + virtual nature of the installation/implementation

- Customer’s pain point from their perspective

It is not enough to have great software. Nor is it enough to have reliable hardware to deliver data. You have to develop industry knowledge and speak the language of your customer. If you fail at any of the three above, your sensor telemetry solution will be outperformed by someone else.

- Hardware: IIoT is implemented successfully when an IIoT service provider can be elastic in their offering. A solution is rarely one size fits all. The ability to modify, expand, and modularize your hardware and service offerings is key. Being agile and understanding is critical to a successful hardware implementation. No one wants to be locked into hardware that is static. Those days are gone. Or at least on their way out!

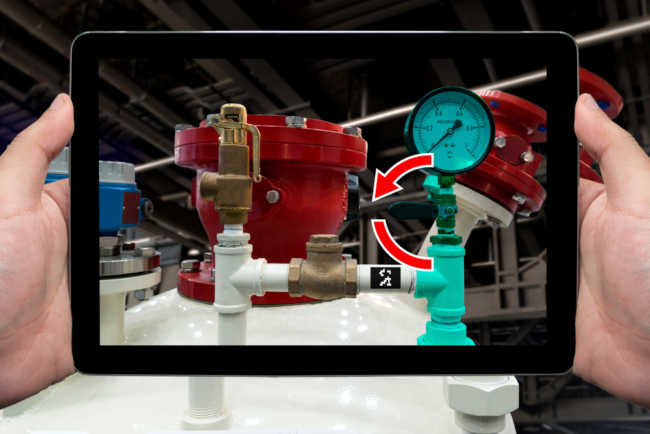

- Software: Business needs are constantly changing. Agility on the software side is also a key part of the sustainable IIoT solution. It is critical to understand the customer’s pain in the field. Get out there and get your boots dirty. See the challenge in situ, with your own eyes and hands. That helps you learn how to change, customize, and amend software to give the customer the real solution they need. It’s wonderful to provide the customer with the exact solution they need even when they can’t describe it. You know what they need because you’ve been in the field, close to the metal, and understand the real challenges. Note that there is a limit here, but often this willingness to be dynamic ends up making features that many customers will use down the road. If customers are asking for a feature to solve their pain point then it’s likely there are others that need the same thing for remote monitoring!

- Customer Service: Is the client getting what they need? Do you have the ability to look past what they want and give them what they need? Is the IIoT solution only providing a partial fix? Information like this can be difficult to elicit from a customer. Excellent IIoT means amazing customer service. Having people that understand personal relationships and care about what their customers are doing is a tremendous competitive advantage. It’s also a tremendous amount of work. And that work can’t be performed by just anyone. A few bad phone calls. A bad email. Then your customer service is a problem for your business. As with any provider, trust plays a significant part in Industrial IoT applications.

As much as IIoT is a software play, the handshake is a critical challenge. This is especially true for the companies that are still sending people out to do a machine’s job. IIoT makes it possible for folks to do more exciting work like analytics, less time driving and a lower environmental impact since money is saved when there are less costs of vehicle maintenance like tires, gas, and oil changes.

In the end, IIoT brings sustainability and improves your business’s bottom line. To successfully deploy Industrial IoT solutions requires a healthy balance between software, hardware, and customer service.

This article was written by Pawel Sasik and originally was published here. Pawel is an IIoT veteran, who developed and deployed real-time industrial IoT solutions across numerous industries, including but not limited to Oil and Gas, Agriculture, Water Resources and numerous others.

This article was written by Pawel Sasik and originally was published here. Pawel is an IIoT veteran, who developed and deployed real-time industrial IoT solutions across numerous industries, including but not limited to Oil and Gas, Agriculture, Water Resources and numerous others.