Where gas and data flow

Equinor’s LNG facility on Norway’s Melkøya Island cools natural gas from the Barents Sea to minus 160 degrees Celsius, fills it into special tanks, and delivers it to ports around the world. To do this work, it particularly also uses digitalization tools from Siemens.

Whether competing in swimming, gymnastics or track and field, athletes have to deliver top performance on the spot. In the past when injuries occurred, medical care was reactive, with patients being treated on an as-needed basis. Today more and more teams are taking a comprehensive approach to athlete health: a whole crew of medical professionals monitors the athletes, reducing the risk for injuries while improving their chances to win. This holistic approach using close monitoring by experts is also being implemented increasingly at industrial plants.

If industrial plants fail, the consequential costs can run into the millions. To prevent this, drive train performance at the Equinor LNG plant on Melkøya Island is continuously monitored with the help of Siemens. The result is higher availability and reduced costs.

Condensed energy

Natural gas reaches Melkøya Island via a 160-kilometer gas pipeline from the Snøhvit field in the Barents Sea. At the island facility, water and CO2 are separated from the well stream before the natural gas is cooled down to minus 160°C and condensed to liquid form, or liquefied natural gas (LNG), and stored in dedicated tanks. In the process the separated CO2 is also cooled to a liquid and then transported back to the Snøhvit field for permanent storage beneath the seabed.

The LNG then leaves the island in custom-built ships destined for ports all over the world. After transport, it is regasified and fed into pipelines.

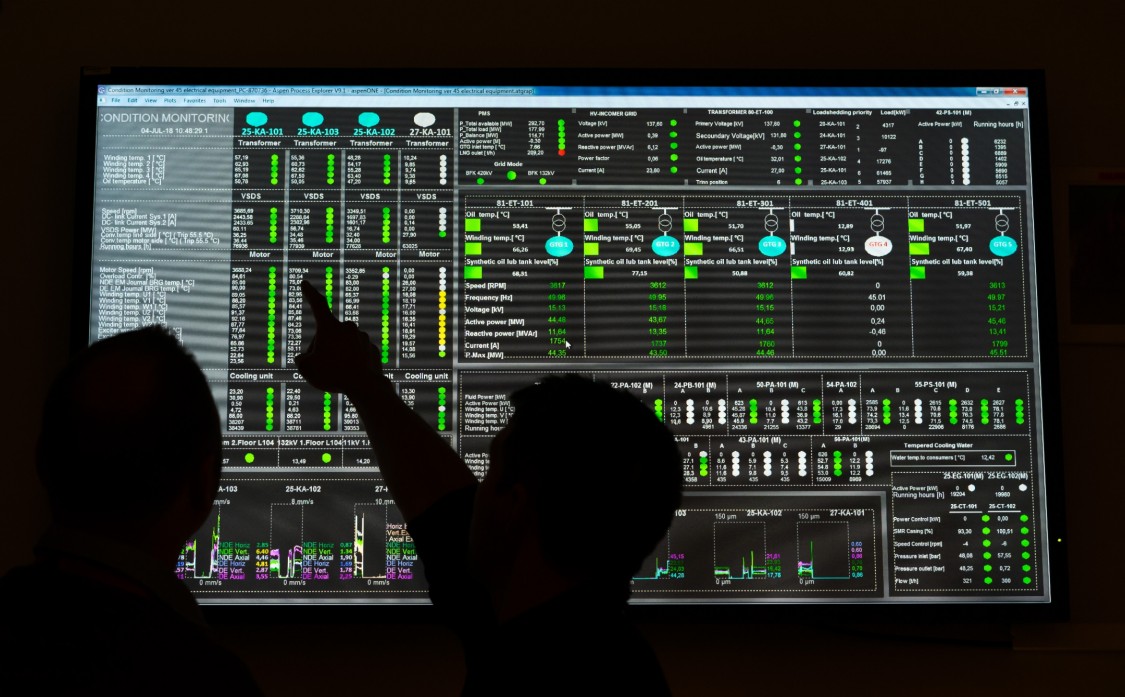

All systems in view: In the central control room, the operating data of Equinor’s LNG plant are continuously monitored

Demand for absolute reliability

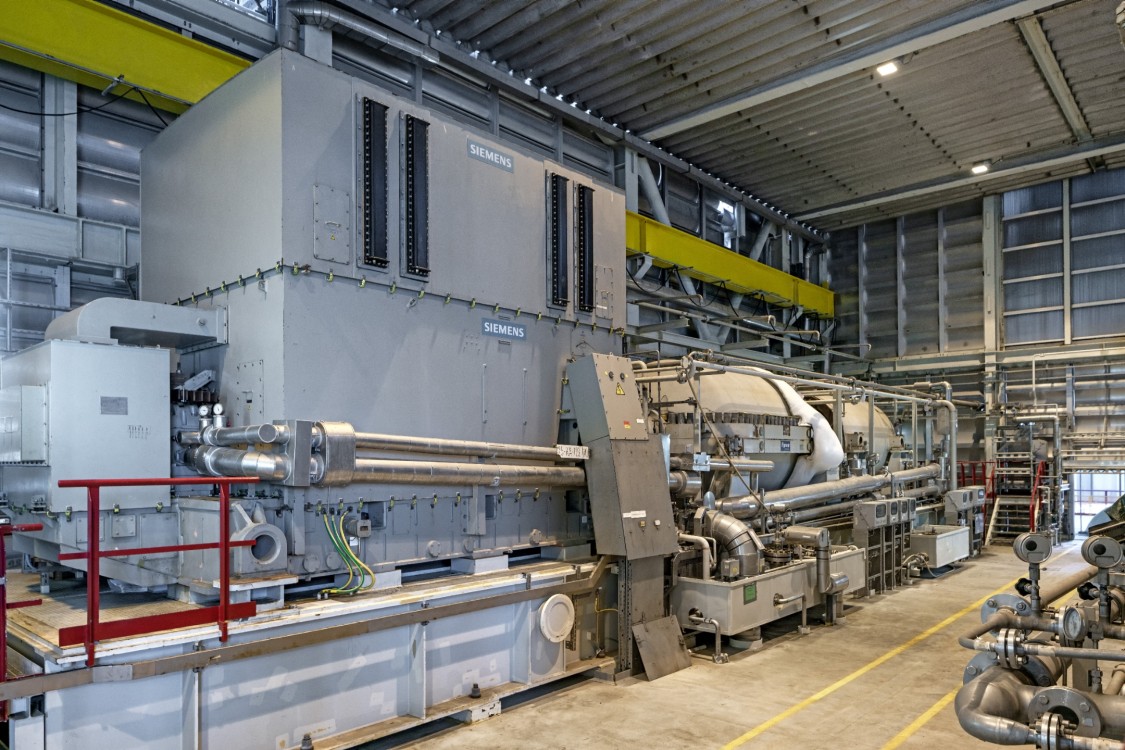

The focus on Melkøya Island is on the liquefaction process. The high-performance compressor trains required for this have to operate reliably, above all because of the site’s remote location far inside the Arctic Circle.

“The operators and service engineers are on a constant watch for optimized solutions to keep production running efficiently, such as by reducing maintenance intervals, assessing the condition of components, and quickly initiating service measures – whatever it takes to avoid surprises,” says Anders Dirdal, Corporate Account Manager at Siemens.

The heart of Equinor’s LNG plant on Melkøya Island is the liquefaction process

Built-in condition monitoring

The electric compressor trains have been equipped with the world’s largest Simotics high-voltage, high-speed 65 MW synchronous motors and Sinamics GL converters. This has led to a high efficiency level and high availability. Condition monitoring and data collection functions can be used to continuously monitor the electrical assets of the entire system. This data enables Equinor staff to carry out precise analyses of component performance and make fine-tuned improvements in efficiency.

In 2013 Equinor introduced a new condition monitoring system for the compressor drive train of the LNG installation. Today, the Sidrive IQ platform from Siemens can be used to monitor, analyze and optimize the compressor drive trains. Since the plant’s launch, the team had learned that to achieve maximum availability, a holistic approach encompassing the whole drive train was required – much like the strategy that winning Olympic teams implement for their athletes’ performance. Together with engineers from Siemens, additional sensors were installed on further components of the drive train and used to collect data on items such as dust flow, magnetic flux density and vibration.

With the help of this data, Siemens service specialists can provide valuable assistance and determine maintenance strategies even more precisely in advance. This makes it possible to avoid unplanned outages and reduce planned downtimes.

Thanks to Sidrive IQ the condition of the electric compressor trains is continuously monitored

Using data for troubleshooting

Sidrive IQ has already helped Equinor’s engineers to correct an issue before it could result in an extended plant outage: Siemens experts in Germany analyzed a critical situation on the basis of data from Sidrive IQ and were able to locate the defective parts and determine the true cause of the fault. They also developed a solution for the problem and created a list of the spare parts needed. Instead of the usual days or even weeks, this all happened within a few hours. In principle, downtimes can be slashed by up to 70 percent and maintenance costs cut by up to 20 percent thanks to Sidrive IQ.

Sidrive IQ always keeps an eye on the operating data of the LNG plant

Upcoming future: digital twin

Equinor trusts in its collaboration with Siemens to keep the LNG facility on Melkøya Island running reliably and efficiently. “Siemens is a trusted partner,” states Gunder B. Gabrielsen, Leader Process Technology Downstream of Equinor at Hammerfest site.

The next step is to develop a digital twin of the compressor drive train to simulate and predict the condition of the high-speed high voltage motors. This makes it possible to extend the service intervals from the current three years to four years. In addition, the monitoring can determine what happens when motors are operated above their nominal capacity for a given period of time.

Just as it takes a team of experts to help athletes bring home Olympic gold, so too are experts needed to prevent expensive unplanned downtime, ensure reliability and safeguard efficiency at industrial sites. And when these efforts are based on digital tools such as the ones in use at Equinor’s Hammerfest LNG plant on Melkøya Island, the results are not just impressive, but show the way to a more efficient, reliable future.

This article was written by Paul Elflein. He is responsible for Corporate Communications at Siemens Large Drives Applications. Originally the article was published here.