How to achieve Overall Equipment Effectiveness (OEE) using Real-time Maintenance (RtM)

What if your production equipment was always available as planned?

What if your cycle time was never compromised because of a damaged machine?

What if your production equipment self-detected and alerted you of quality defects?

Applying Real-time Maintenance (RtM) technologies to your production equipment increases equipment availability, maintains machine throughput, and minimizes material losses.

Common industrial maintenance strategies

There are 3 basic types of industrial maintenance processes, and each have costs associated with them.

• Reactive maintenance — highest total cost of ownership. Run-to-failure strategy and unplanned downtime is usually more expensive than planned downtime and typically there is secondary damage to other components.

• Preventative maintenance— downtime is scheduled prior to failure. Carries a high cost because parts and labor are consumed prematurely.

• Predictive or Condition-based maintenance — uses RtM technology to optimize equipment use. Maintenance is performed only when necessary, without production loss.

What is Overall Equipment Effectiveness (OEE)?

Overall Equipment Effectiveness or OEE is one of the primary RtM metrics used to determine how well your production equipment is performing. Applying RtM technologies provides visibility to machine operation and therefore allows you to reduce losses. The following chart is widely used to explain OEE.

RtM technologies for predictive maintenance

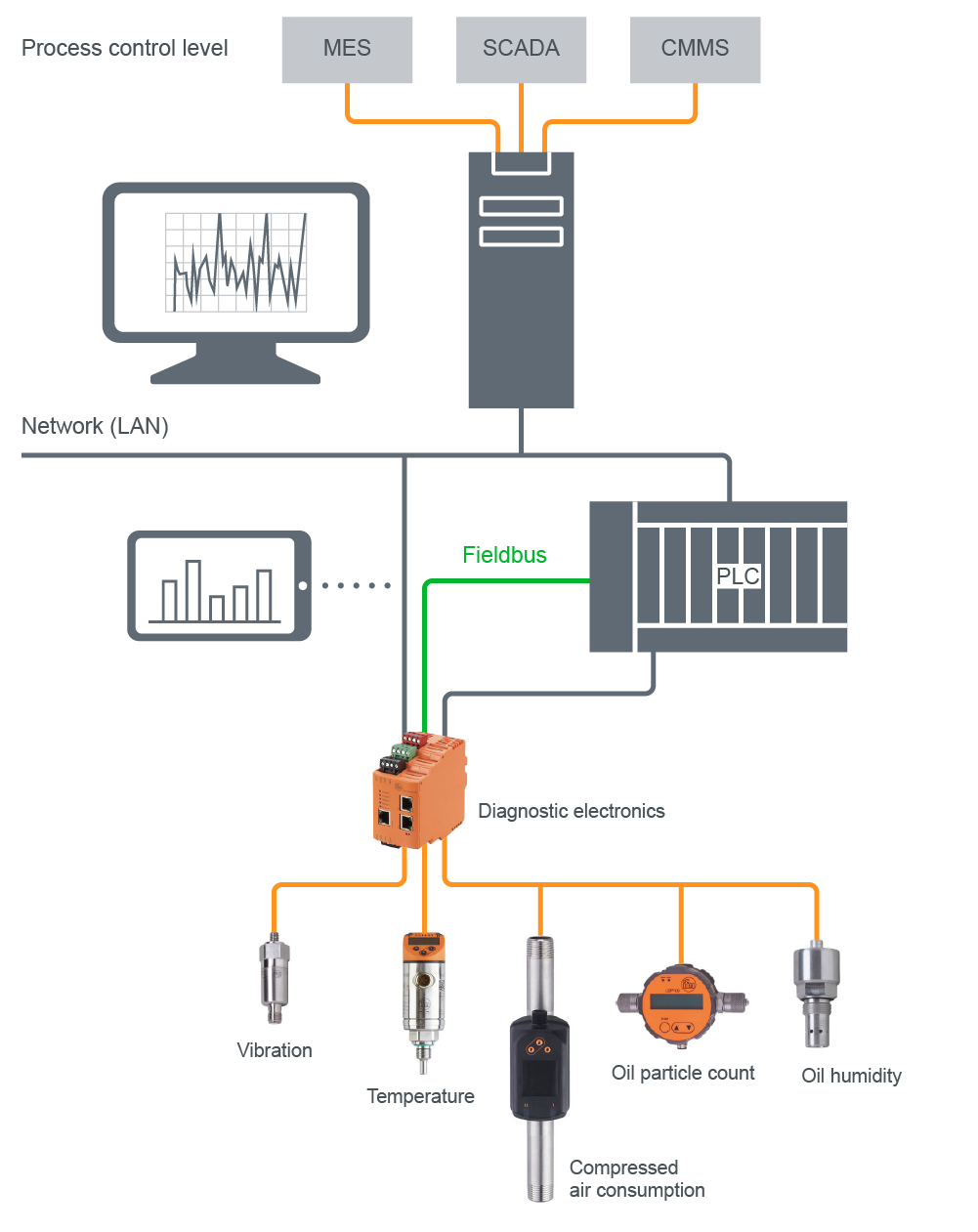

Advances in technologies for industrial networks, reduction in size and cost of computational power, and advances in smart sensors are making predictive systems a reality. These innovations are changing the way companies manage their industrial equipment maintenance. Operational worthiness in real time is key to improving OEE (Overall Equipment Effectiveness) and increasing profits. Implementing RtM is at the core of any Industry 4.0 initiative. With ifm RtM products, machines can communicate their operational status in real time, automatically plan maintenance, reduce downtime, and improve quality – all improving your bottom line.

Image source: IFM

An RtM system ties operational data together with condition-based monitoring data to improve information quality and help you make informed decisions.

Monitor oil quality in real time

Oil systems are found on nearly all industrial machines. Whether the oil is used to lubricate rotating components or to transfer hydraulic energy, maintaining a contaminate-free oil supply is necessary for trouble free operation.

Oil quality sensors monitor oil degradation and moisture ingress in real time, extending machine availability and performance. Premature time-based oil changes are expensive and can be replaced by condition-based oil changes, improving machine performance, and reducing operating costs. Equipment is protected from damage due to contaminated oil. Real-time insight of developing mechanical issues can be quickly identified and corrected before primary, secondary or catastrophic damage occurs.

How to Improve Overall Equipment Effectiveness?

OEE (Overall Equipment Effectiveness) is the gold standard for measuring manufacturing productivity. Simply put – it identifies the percentage of manufacturing time that is truly productive. Find more use cases of OEE in IoT.

Availability and performance are improved through real-time oil condition monitoring.

• Safeguard machinery from damage

• Increase productivity and reliability

• Extend intervals between oil changes

• Reduce maintenance costs

• Reduce waste oil disposal costs

• Improve total cost of ownership of equipment

Read more about RtM and OEE on IFM’s website.