Industry’s first AI-driven remote machine monitoring solution for OEM’s & machine builders

What if you could stop a machine before a catastrophic failure? What if you could detect a bearing wearing faster than expected, before it was scheduled for maintenance and before it causes downtime? What if you could diagnose and resolve machine downtime for your customers without sending a technician on site?

MachineMetrics is answering these questions with the release of their latest application: MachineMetrics Service. MachineMetrics Service is the industry’s first AI-driven remote machine monitoring solution designed for CNC machine builders, providers, and distributors; a predictive analytics application on the MachineMetrics Industrial IoT platform that allows service teams to remotely monitor and manage machine assets in the field and at customer sites in real-time.

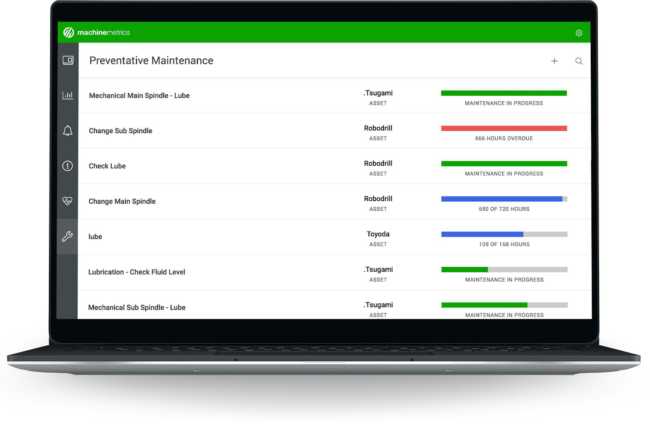

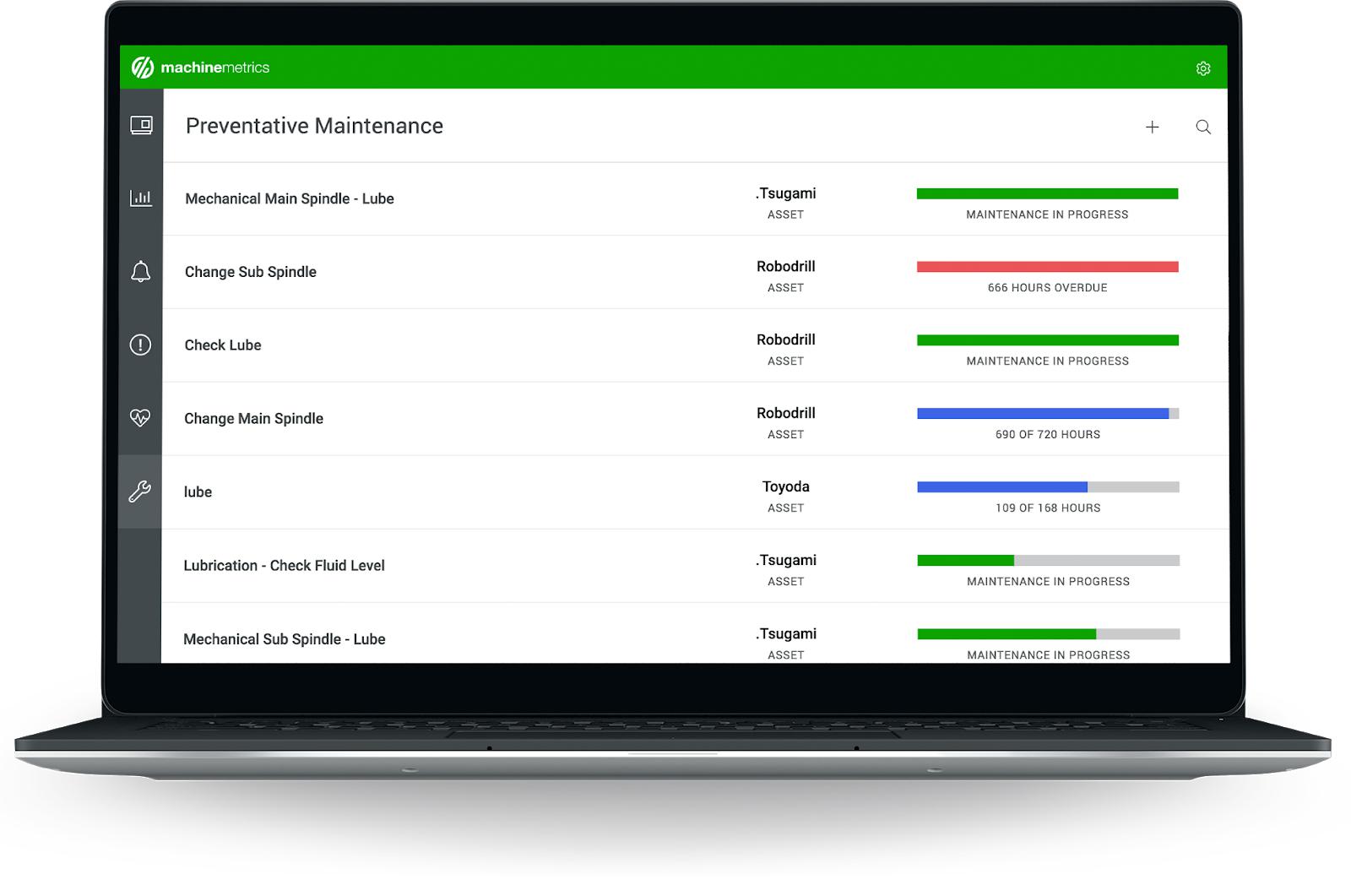

Using MachineMetrics Service, equipment manufacturers can transform their approach to service with the ability to see, understand and take action on their customer’s real-time machine data from anywhere at any time. The results? Faster service when customers have machine problems, reduction of on-site service visits by 10-20%, optimization of preventative maintenance plans, validation of warranty claims, and identification of new service opportunities through predictive maintenance pre and post-warranty period.

When customers require after-sales service, they expect their problem to be solved with minimum delay. Too many service calls require expensive and time-consuming on-site visits. Thus, equipment providers require remote access to monitor and assist with user operations to troubleshoot problems, resolve service events and monitor preventative maintenance tasks, all without leaving their office.

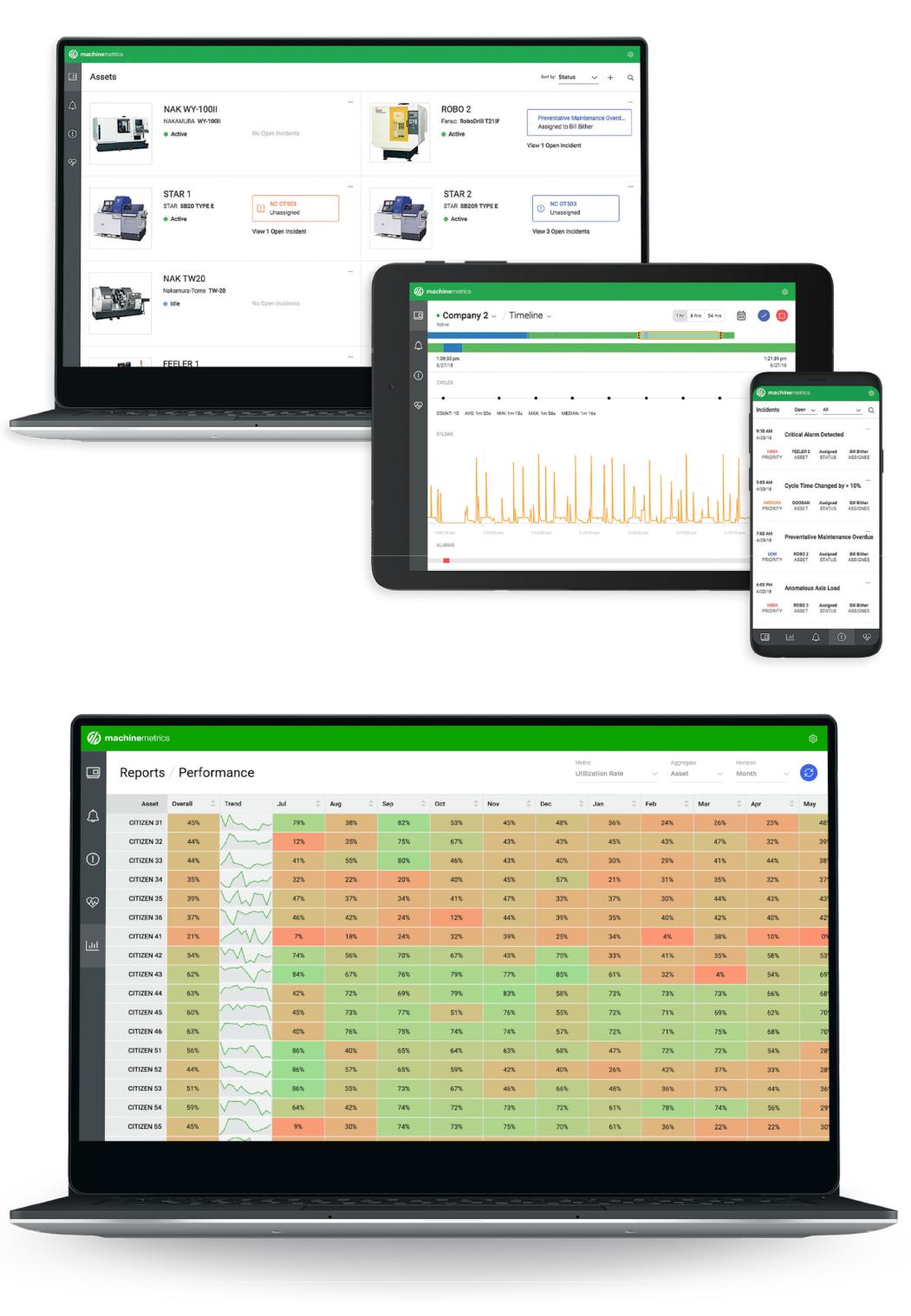

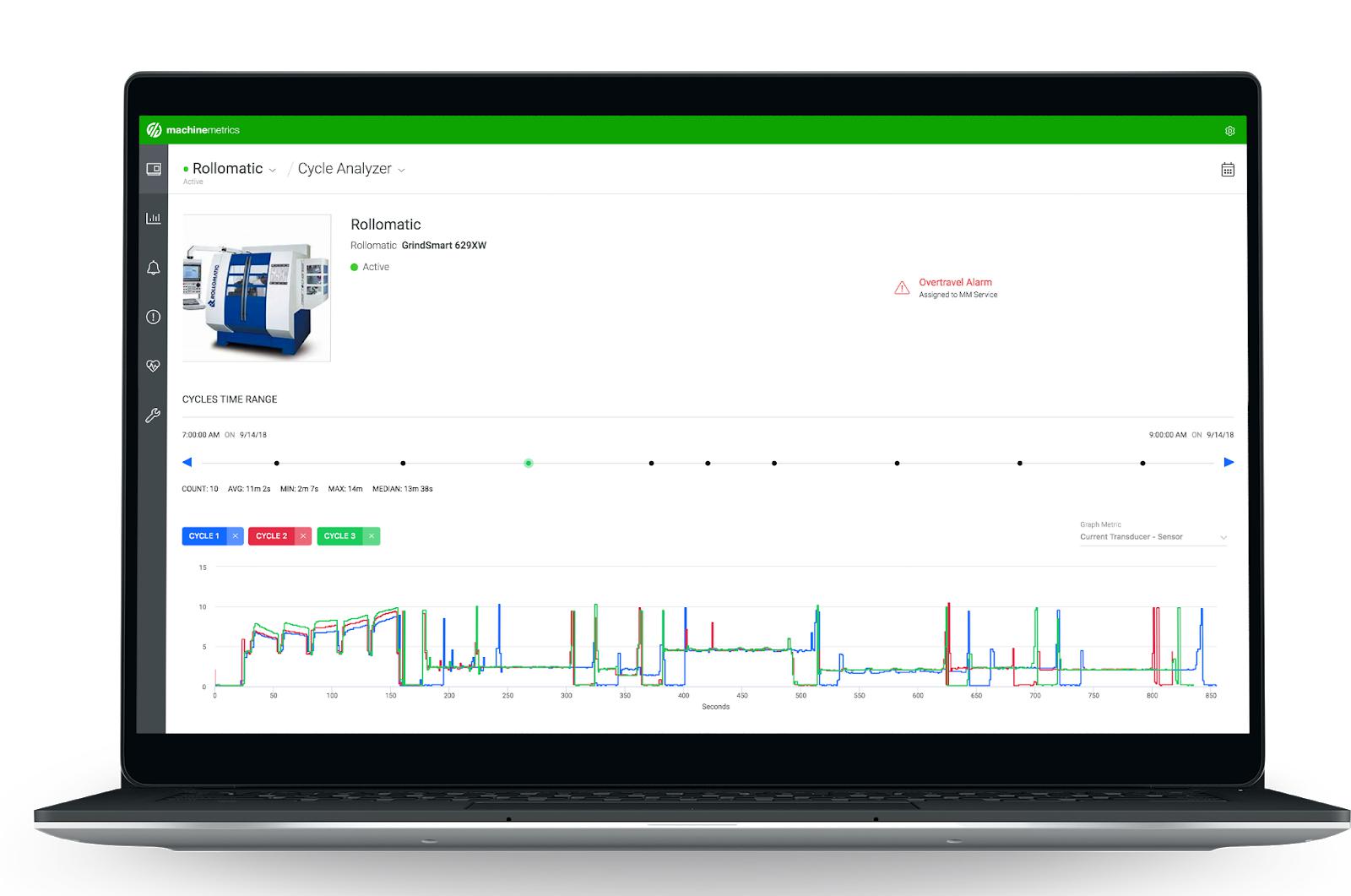

The historical and real-time machine data collected from MachineMetrics allows equipment manufacturers to gain insight into customers’ equipment health and condition, identify new service opportunities with analytics and reporting, predict and deliver early warning of potential equipment failures, highlight elevated risk areas that lead to machine downtime, or even determine to take preventative action before it impacts a customer’s machine performance.

How it works is actually quite simple: Any equipment provider, OEM or distributor, can install MachineMetrics Edge device on a new machine sold to a customer or retrofit any machine currently in the field. MachineMetrics Edge has the ability to connect to the machine’s PLC and any additional sensors into the electrical cabinet of the machine and allows for the data to be visible to the customer and shared with the equipment provider. There’s no need to install on customer’s internal IT infrastructure as MachineMetrics Edge comes with included cellular support. Once installed, the provider can add the device to a list of machine assets accessible via the MachineMetrics Service app and associate that machine with the location of the customer. Once the customer receives the machine and powers it on, that machine will appear active on the provider’s list of assets.

Encrypted data is then streamed to the secure MachineMetrics cloud where the data is structured and aggregated to enable visualizations and analytics for service teams to monitor industrial equipment. Access to the historical and real-time data is available through open APIs. Real-time dashboards, historical analysis, and integrations with other systems can be built with these APIs.

The MachineMetrics AI analytics engine will monitor any connected machine’s conditions and other manufacturing data points and initiate a workflow action or text notifications when a monitor is triggered such as an alarm state, a threshold is exceeded, a preventative maintenance task is due, or an anomaly is detected. This ability can prevent thousands of dollars of equipment replacement costs and days of downtime, not to mention unearth new service opportunities that were never visible to service teams before.

Data from thousands of connected machines allow the MachineMetrics Data Science team to work with service teams to identify trends and develop standard preventative maintenance and repair schedules that benefit both the service team and the customers. So while service teams are focusing on addressing issues that may immediately impact their customers, MachineMetrics can help identify big-picture issues that benefit both the equipment provider and the end-user. Find out top 10 reasons to implement a remote monitoring system leveraging IIoT.

“For years now we have been working directly with manufacturers to improve manufacturing equipment uptime, OEE, and productivity with real-time machine monitoring and analytics,” said Bill Bither, CEO of MachineMetrics, “By allowing machines to be monitored remotely and in real-time, we are enabling OEM’s to extend these benefits to their customer base while providing them with faster, better service. Our data science team is working closely with the data to deliver optimized preventative and predictive maintenance specific to their machines to improve machine uptime.”

OEM’s are already experiencing the benefits of implementing MachineMetrics Service: “Tsugami/Rem Sales is thrilled to be working with MachineMetrics, bringing cutting edge, disruptive technology directly into our end-users’ businesses,” explained Michael Mugno, Vice President, Tsugami/Rem Sales. “The addition of MachineMetrics Service to our Swiss-turn machine platform packages allows users to collect data on machine health, production status, downtime, and so much more that they may never have known existed – bettering businesses across the industry.”

About MachineMetrics

MachineMetrics is an award-winning manufacturing analytics platform for discrete manufacturers. Their Industry 4.0-ready AI solutions work out-of-the-box to increase productivity through edge connectivity, real-time visibility, deep manufacturing analytics and AI driven predictive notifications. MachineMetrics has simplified Industrial IoT to digitize the shop floor and enable teams to drive decisions with machine data.

Now integrated into factories across North America and Europe, MachineMetrics is the fastest growing manufacturing analytics provider in the industry, featuring global customers and partners such as Fastenal, Snap-On Tools, Gardner Denver, TurboCam, Shiloh Automotive, McKinsey and Co., SECO Tools and Tsugami/Rem Sales.

Originally this article was published here. Learn more about MachineMetrics solutions here.

Graham Immerman is Director of Marketing for MachineMetrics, a venture-backed manufacturing analytics platform. Graham has quickly become an authority on digital transformation and the application of IIoT technology for the manufacturing industry. An accomplished leader and experienced start-up veteran with an integrated background in digital, social, traditional, account-based marketing, growth strategies, and business development.