How Digital Transformation Creates New Revenue Streams in Manufacturing

Rethinking Value in Manufacturing

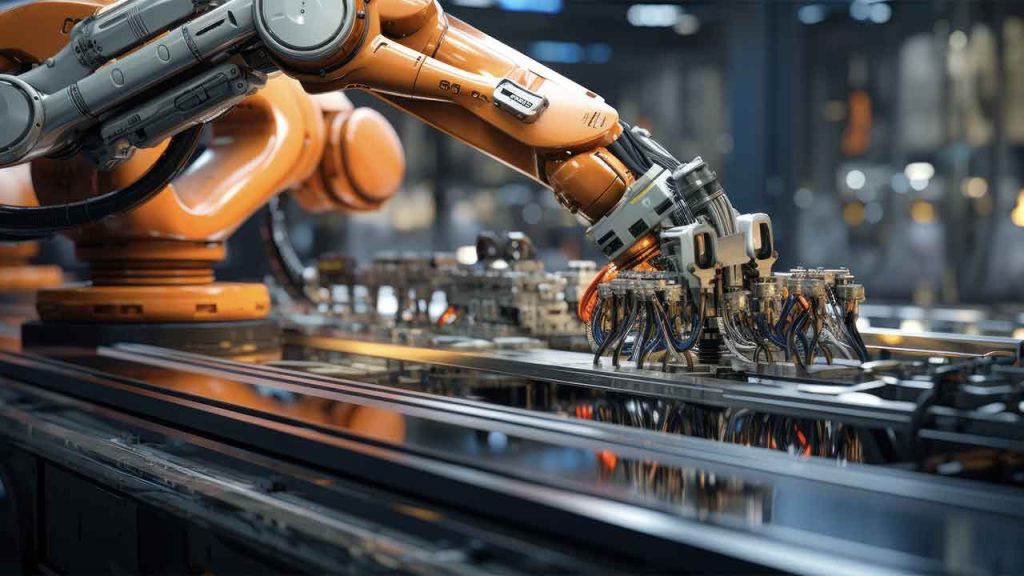

Digital transformation in manufacturing is no longer just about optimizing efficiency or cutting costs—it’s also about unlocking new revenue opportunities. By leveraging cutting-edge technologies like IoT, AI, and cloud computing, manufacturers are moving beyond traditional production models to create innovative products, services, and business models.

This article explores how digital transformation fosters revenue growth by enabling manufacturers to expand their offerings, improve customer experiences, and capture untapped market opportunities.

- From Products to Services: The Rise of Servitization

Servitization refers to the shift from selling products to offering them as a service, often bundled with maintenance, monitoring, or upgrades. Digital transformation technologies make this shift viable and scalable.

- Example: Industrial equipment manufacturers now use IoT sensors to offer Equipment-as-a-Service (EaaS) models. Instead of selling machines outright, they charge customers based on usage or performance, ensuring steady recurring revenue.

- Impact: This creates long-term customer relationships, reduces market volatility, and opens doors for upselling additional services.

- Data Monetization: Turning Insights into Income

The data generated by connected devices and manufacturing processes is a goldmine for manufacturers. By analyzing this data, companies can offer value-added services and insights to customers and partners.

- Example: John Deere transformed its traditional machinery business by integrating IoT into its tractors. Through its Operations Center, the company provides farmers with real-time data on soil quality, weather patterns, and crop health.

- Impact: This not only enhances customer value but also generates new revenue streams by selling data-driven services and insights.

- Customization at Scale: Meeting Consumer Demand

Consumers and businesses increasingly demand personalized products. Digital transformation technologies like additive manufacturing (3D printing) and AI-driven design tools allow manufacturers to deliver customization at scale.

- Example: Shoe manufacturer Adidas uses 3D printing to produce customized midsoles for its Futurecraft 4D line. Customers can design their footwear, and Adidas can produce them efficiently without high upfront tooling costs.

- Impact: By charging a premium for personalized products, manufacturers tap into niche markets and boost their profit margins.

- Digital Marketplaces: Expanding Distribution Channels

Digital platforms are enabling manufacturers to reach customers directly, bypassing traditional distributors and intermediaries.

- For example, some companies allow manufacturers to buy and sell industrial IoT applications and solutions via a digital marketplace.

- Impact: These marketplaces provide access to global customers, reducing reliance on traditional sales channels and increasing market reach.

- Predictive Maintenance Services: A New Value Proposition

Digital transformation technologies like IoT and AI enable manufacturers to offer predictive maintenance as a service. By monitoring equipment in real time, manufacturers can predict and prevent failures, reducing downtime for customers.

- Example: Siemens integrates IoT-enabled predictive maintenance into its manufacturing equipment. Customers pay for continuous monitoring and insights that optimize equipment performance.

- Impact: This model shifts revenue from one-time equipment sales to ongoing service contracts, providing a steady income stream.

- Green Manufacturing: Capitalizing on Sustainability

Sustainability is a growing priority for consumers and businesses. Digital tools help manufacturers adopt greener practices while creating new revenue opportunities.

- Example: Companies are using blockchain technology to certify sustainable sourcing and production. Manufacturers can charge a premium for verified green products.

- Impact: By aligning with environmental goals, manufacturers appeal to eco-conscious consumers and create a competitive edge.

Challenges in Monetizing Digital Transformation

Despite its potential, creating new revenue streams through digital transformation isn’t without challenges:

- Initial Investment Costs: Adopting digital technologies can require significant upfront investment.

- Cultural Shifts: Transitioning to new business models requires buy-in across the organization.

- Data Privacy Concerns: Monetizing data requires robust security measures and regulatory compliance.

A Blueprint for Growth

Digital transformation is not just a technological upgrade—it’s a strategic shift in how manufacturers operate and deliver value. By embracing new business models, leveraging data, and focusing on sustainability, manufacturers can unlock significant revenue potential.

As industries evolve, those that capitalize on the opportunities offered by digital transformation will position themselves as leaders in the manufacturing space, driving innovation and growth for decades to come.

Sources and References

- John Deere Technology

- Adidas 3D Printing

- Siemens IoT Solutions: Siemens IoT

- Bosch IoT Suite: Bosch IoT

Related articles: