Are You Underestimating the Cost of Manufacturing Downtime? | SPONSORED

For most manufacturers, downtime is the single largest source of lost production time. Although some may acknowledge this, the cost and extent of manufacturing downtimes tend to be grossly underestimated.

Determining the Real Cost of Manufacturing Downtime

Most manufacturers are aware they are losing time and money because of downtime. However, many manufacturers can not accurately answer the following questions.

- How much does downtime cost your plant each year?

- What amount of time can any specific machine go down without affecting another process?

- Why are your machines experiencing downtime and failures?

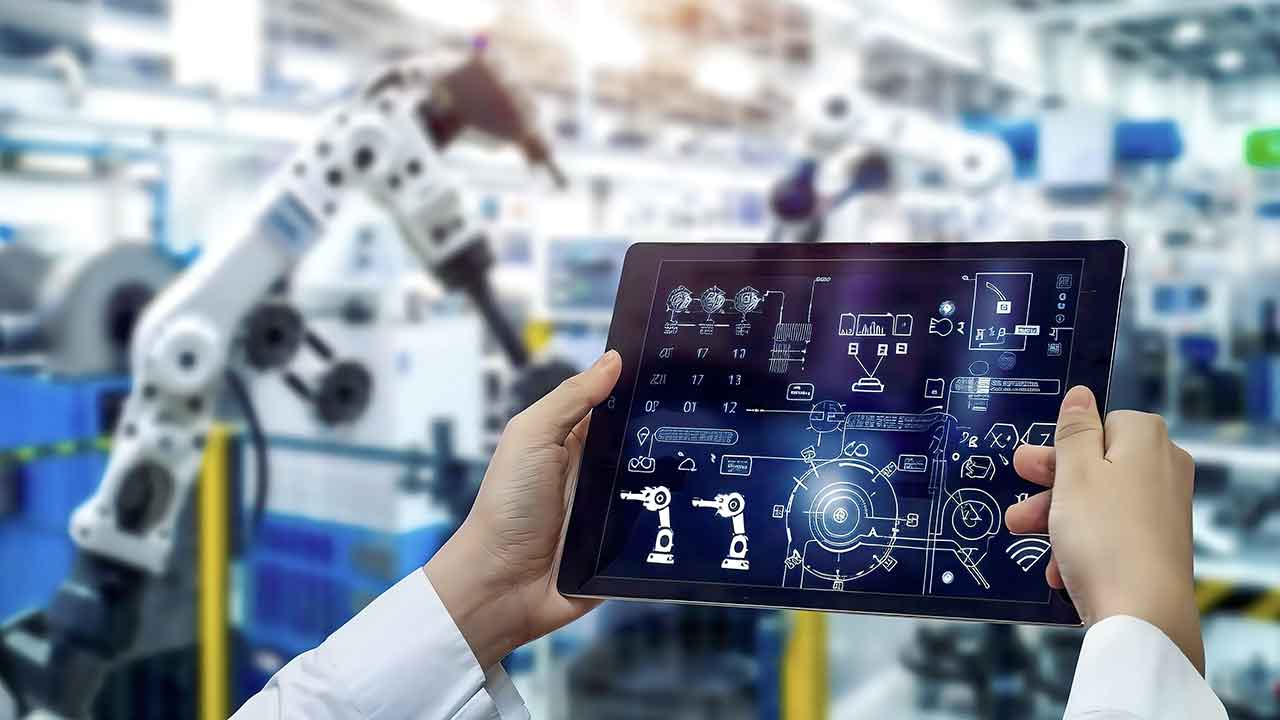

It is obvious that manufacturers benefit dramatically from automated data collection systems vs. manual data collection. Platform software should connect equipment and people to gain a full perspective about what is happening on the shop floor in real-time. Traditional or manual documentation takes time between reporting the data, analyzing it, and extracting useful information to improve, correct, or even know that downtime occurred. Operators might also be busy, tired, overworked, monitoring multiple machines, etc., which leads to inaccurate reports or reports not being filed. The ability to automatically collect real-time data from manufacturing equipment as well as contextual data from operators, via tablets placed at each machine is of great value.

If You Don’t Know, You Can’t Act

Research shows that the average rate of machine utilization is far lower than manufacturers expect. To increase machine utilization, key stakeholders including operators, technicians, and managers need accurate real-time production data. Making decisions without data leads to decisions based on gut instinct, resulting in increased problems, failures, and frustrations.

Read the full post from Machine Metrics which explores the value of real-time shop floor visibility and how downtime events can be quickly resolved by leveraging automated notifications and workflows.

About the Author

Bill Bither, CoFounder and CEO, Machine Metrics

Bill Bither, CoFounder and CEO, Machine Metrics

Bill is an experienced software entrepreneur, and the founder of Atalasoft, an enterprise software company that sold to Kofax (now Lexmark). Prior to Atalasoft he worked in aerospace manufacturing.

Learn more about how manufacturers can benefit from IIoT initiatives at IIoT World’s Digital Manufacturing Day on December 8, 2021. The first 500 tickets are free, so register today.