Artificial Intelligence Opportunities: A More Intelligent Manufacturing Industry

In a 2016 article from Business Insider, General Electric described what an ideal intelligent factory would look like. Their vision for the “Brilliant Factory,” as they called it, would start with automatic ordering based on detected customer need, and use 3D printing technologies to design, prototype, and test a new part in hours rather than days or weeks.

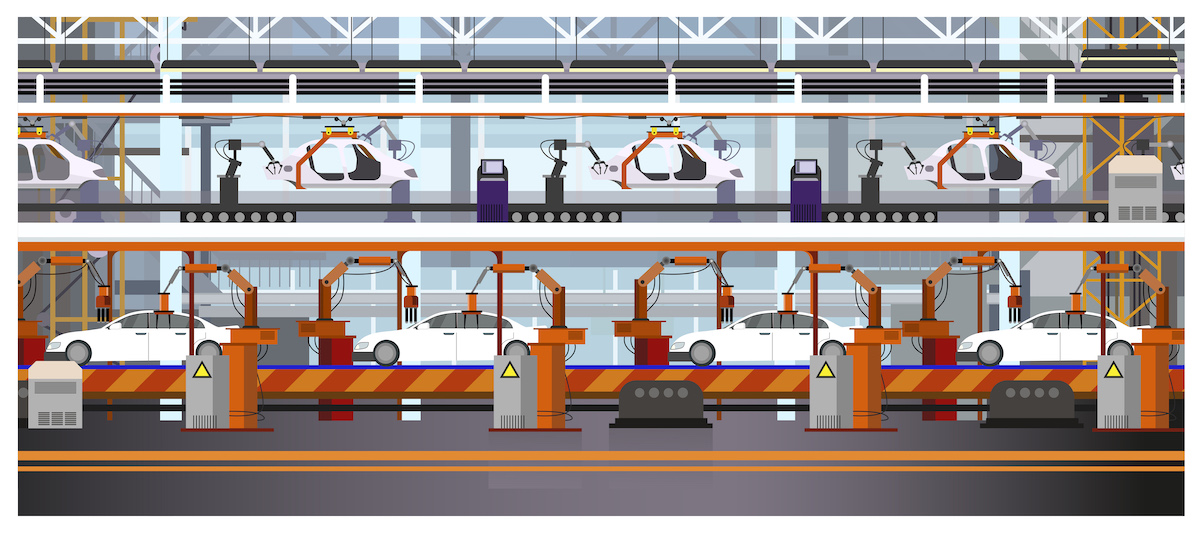

Streamlining production would be next, with highly intelligent robots bearing a majority of the assembly workload. These stages would be continuously monitored by artificial intelligence (AI) technologies to detect abnormalities or faults, and eliminate downtime in the process.

While posing an interesting trajectory for the manufacturing field, this “Brilliant Factory” remains in the future for now. However, current artificial intelligence opportunities allows manufacturing to become smarter, with a focus on research and development, procurement, and assembly line processes.

A “smart” foundation:

Research & Development

Adaptation and innovation are vitally important to the manufacturing industry today. Artificial intelligence has vast potential to help engineers’ and researchers’ approach as well as mitigate the challenges produced by fierce competition, continual change in consumers’ product preferences, and budget constraints. Manufacturers constantly search for the competitive edge keeping them afloat in a crowded industry subject to volatile conditions, such as economic slowdowns. AI-powered technologies facilitate real-time negotiations and interactions with regulatory organizations. This, in turn, contributes to shorter development cycles and faster product-to- market times.

Consumers’ ever-changing needs and penchant for customization require manufacturers to place a great deal of importance on their productivity and efficiency to keep pace with this demand. Natural language processing and deep learning, two key AI technologies, have potential to optimize engineers’ work processes. These AI-powered technologies could integrate client feedback into the production or design process in real time, which would eliminate waste and improve engineering efficiency.

In an industry where profit margins are already minimal, manufacturers constantly search for efficiencies. The industry can utilize artificial intelligence technologies to make value-based decisions, thereby ensuring optimal use of resources. For example, a car manufacturer could use AI-powered technology to provide a data-driven decision to improve the horsepower of a car by showing that the cost of the increase justifies the return when taking it to market.

Further reading: If AI has the power to transform all industries, why hasn’t it?

Procurement

Many project managers face the challenge of product design synchronization with process capabilities. Product design challenges are exacerbated when factories have non-collocated design engineering support scattered across the globe with limited visibility into operations health (inventory, design, supplier, machine health, scheduling). Fortunately, providing data-driven solutions to complex problems is an area in which artificial intelligence excels.

A more efficient and conclusive approach to procurement will help balance supply chain and optimize inventories in real time, therefore reducing inventory costs. AI-powered technologies provide transparency on supplier machine availability, performance, and downtime. More about Unplanned Downtime: Causes, Calculations, and Cures

Similarly, predictive and prescriptive analytics can benefit supply and demand planning. Predictability in operations has long been unexplored by manufacturers: Most of the data that operators have been able to collect and analyze in the past is capable of presenting past information for human processing, but never before have machines been able to essentially teach themselves what’s next.

Assembly line

Downtime substantially impacts the manufacturing space, and anything that effectively remedies unplanned interruptions should not be taken lightly. Like procurement, assembly line processes can use AI-powered technologies to reduce downtime and bring predictability to operations.

An article from McKinsey Quarterly explains, “Because of the prevalence of such predictable physical work, some 59 percent of all manufacturing activities could be automated, given technical considerations.” The ample opportunity for automation in manufacturing and specifically in assembly processes only scratches the surface of how AI can be beneficial.

Every year, manufacturers lose time and resources due to inefficiencies caused by existing fault detection and classification tools. Current tools remain inaccurate and, due to a static approach to detecting faults, do not bring the certainty needed to ensure an efficient assembly process.

Product design synchronization is another area that needs to be addressed with AI-powered technologies. This challenge is generally exacerbated when the factory has remote design engineering support with limited visibility into operations health. Artificial intelligence can provide clarity to the product assembly process and put all parties on the same page. More about The Intelligent Edge: What it is, what it’s not, and why it’s useful

Using predictive and prescriptive analytics through machine learning effectively makes assembly workers’ lives better by bringing predictability and certainty to operations. Accurately predicting defaults or production interruptions, prescribing the remediation of assembly errors, retaining knowledge to flatten the learning curve for new operators, automating risky activities, and incorporating deep learning to real-time information flows for visibility on risk management are all possibilities for AI-aided efficiency in assembly processes.

Although ample opportunity exists for AI improvements in the manufacturing space, there is still work to do before the solutions can see full implementation.

The article was written by Usman Shuja, General Manager Industrial IoT (IIoT) at SparkCognition. Prior to SparkCognition, Usman worked as a management consultant at the Boston Consulting Group (BCG) and in software development and sales roles at IBM.

The article was written by Usman Shuja, General Manager Industrial IoT (IIoT) at SparkCognition. Prior to SparkCognition, Usman worked as a management consultant at the Boston Consulting Group (BCG) and in software development and sales roles at IBM.