How Is Industry 4.0 Transforming Manufacturing and Supply Chain Management Globally?

As per many historians and economists, the second half of the 18th century was one of the most crucial periods in human history as the inventions and developments in this period led to the start of the first Industrial Revolution. Also called Industry 1.0, the phase was characterized by transition from an agrarian, handicraft-based economy to a stable manufacturing-based system fueled by scientific and technological progress. In subsequent years, Industry 2.0 and Industry 3.0, driven by electricity and IT, further transformed the manufacturing sector. In the past few years, with innovations such as artificial intelligence, machine learning, and IoT, a new era of business design and manufacturing has commenced, popularly known as Industry 4.0.

Opening new dimensions in manufacturing and business operations

Industry 4.0 can be defined as an advanced phase of manufacturing that is based on foundational principles of data connectivity, analytics and intelligence, robotics, and human-machine interaction. The growing need to improve efficiency, adapt to market unpredictability, develop new enterprise models, and streamline supply chains has ushered in a new age of business operations. The term has become quite popular since 2016 when Klaus Schwab, executive chairman and founder of the World Economic Forum, used it to signal a change in industrial capitalism.

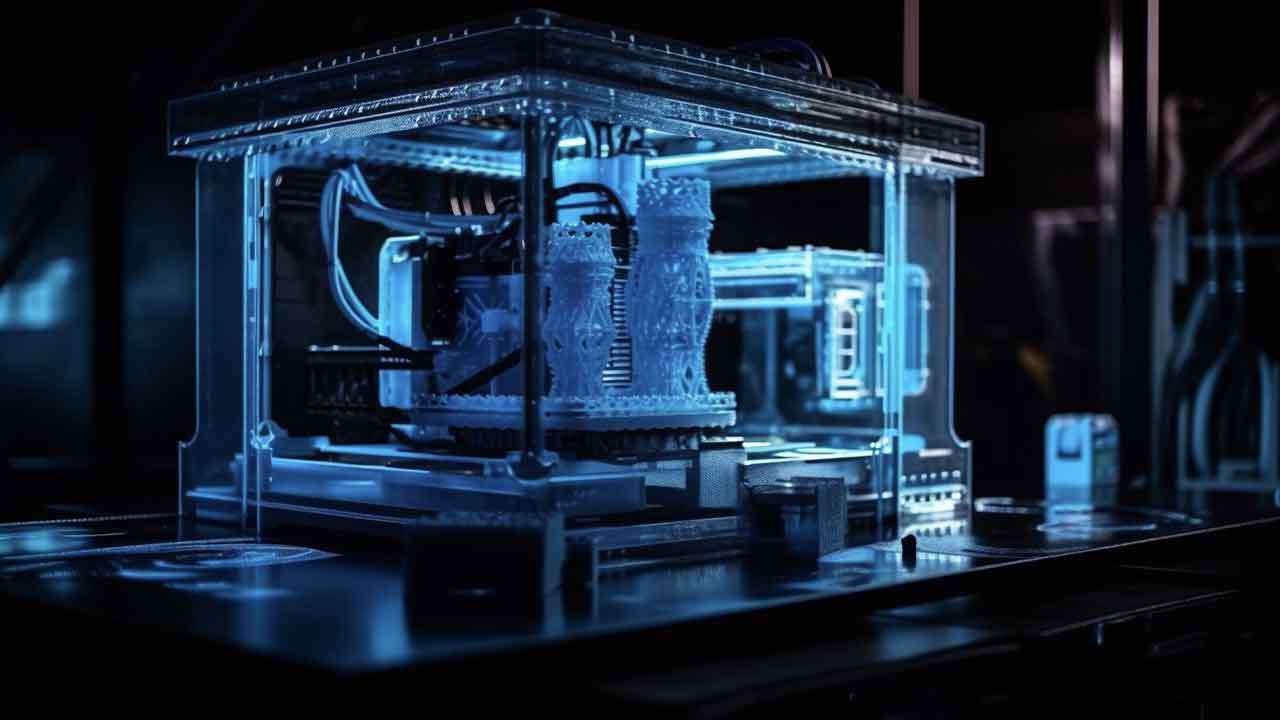

In recent times, this new model has been used to transform all levels of manufacturing. For instance, modern-age machinery and equipment are fitted with IoT-powered sensors to enhance productivity in manufacturing activities. These machines are generally provided with an IP address that helps in connecting them via a web-enabled network. Furthermore, these sensors continuously keep collecting data in real-time which aids the operators in monitoring the performance of the equipment. This also enables users to predict and detect problems in the processes and resolve them proactively, thereby reducing downtime and repair costs. In this exercise of anomaly detection, data analytics, AI, and machine learning algorithms also play a major role as their predictive maintenance capabilities make it easier to identify potential issues and address them through automation.

Advancements in Industry 4.0 revolutionizing the field of supply chain management

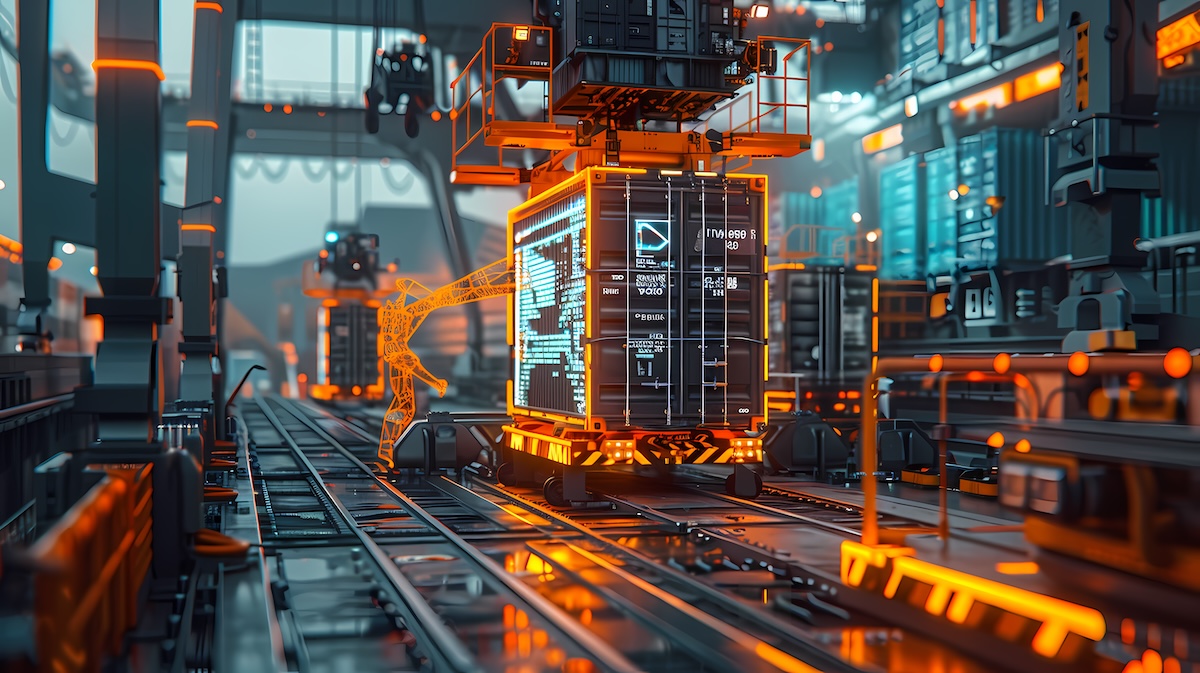

Another area that has witnessed a huge upheaval with the introduction of Industry 4.0 is supply chain and inventory management. Along with emerging technologies such as AI and IoT, this set of advanced manufacturing techniques also makes use of cloud computing to overcome the traditional constraints associated with connectivity. In the age of globalization, this feature becomes even more important as trade barriers have hampered global supply chains, thus causing problems of shortage and inflation.

Over the years, the rising geopolitical tensions and conflicts across the globe have made the issues associated with supply chains quite apparent. In such a scenario, improving the visibility of the logistics sector becomes vital to enhance the trust of customers with respect to the company. Increased transparency in supply chains also translates to accountability and optimized performance of the stakeholders, which ultimately improves the decision-making capabilities of businesses and reduces the overall costs of operations. The deployment of automation tools to perform repetitive tasks and employ manual labor for more productive work is another important feature of Industry 4.0. Finally, from the perspective of consumers, the use of these innovations helps them in getting personalized services and products.

To summarize, the advent of AI, machine learning, IoT, cloud computing, and data analytics has triggered a new wave of techniques and approaches that are collectively known as Industry 4.0. Apart from transforming the manufacturing sector, this set of technologies has also revolutionized the sphere of supply chain management, thus a transition in the global economy.

About the author

This article was written by Onkar Sumant. He has been working as a Senior Manager at Allied Market Research and has vast experience in the domain of information and communication technologies. He has been at the forefront of developing strategies and formulating plans to implement customer-centric approaches in the company.